Contact Info

Unit 1011, Pingning Industrial, Longhai District, Zhangzhou City, Fujian Province

New York.

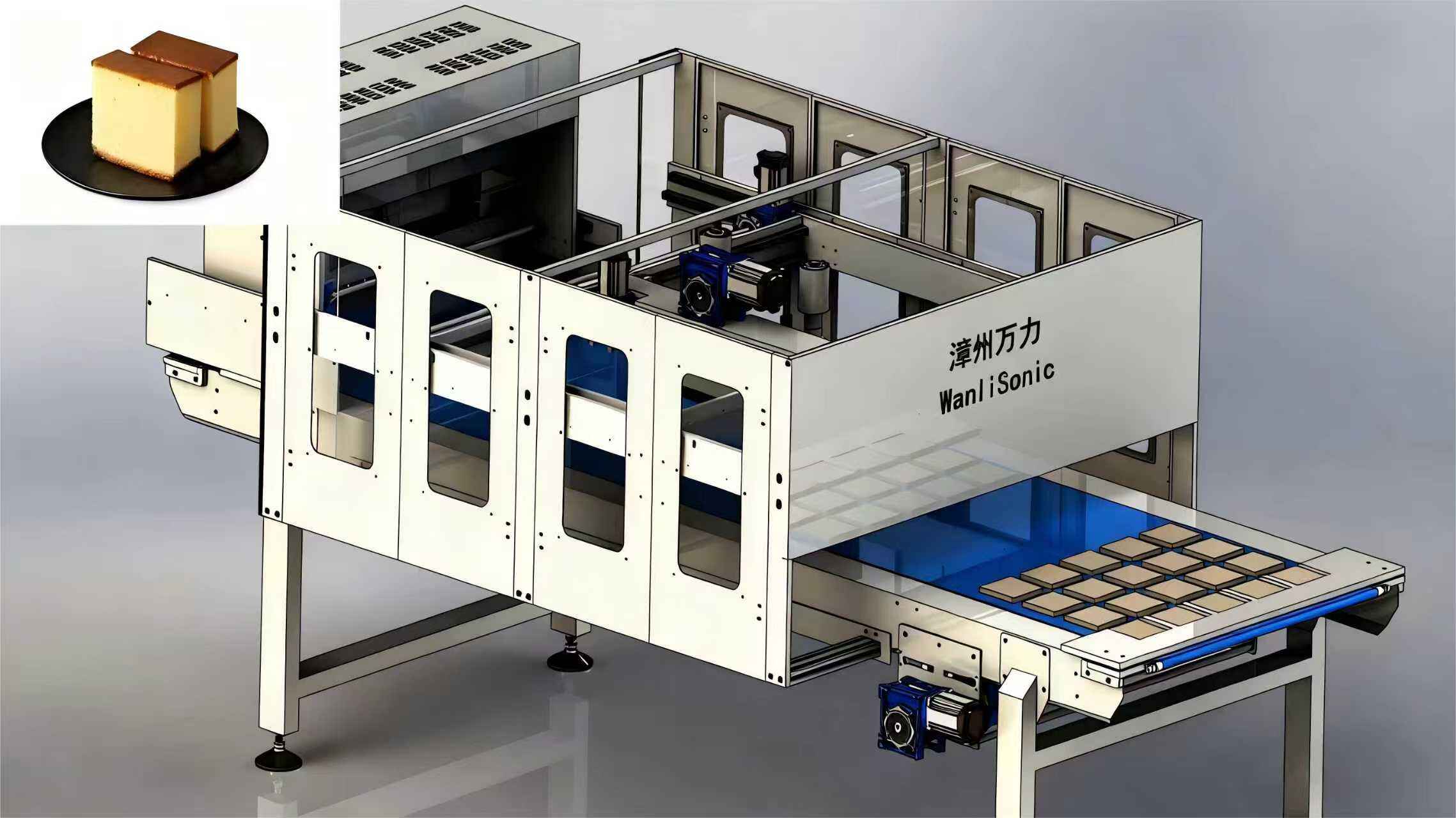

In modern baking production, cutting quality, efficiency, and hygiene safety are key factors determining product competitiveness. Leveraging years of R&D experience, Wanli introduces the fully automatic ultrasonic cake cutting machine, helping global baking enterprises achieve high-precision, low-waste slicing processing.

Overview of Ultrasonic Cutting Technology

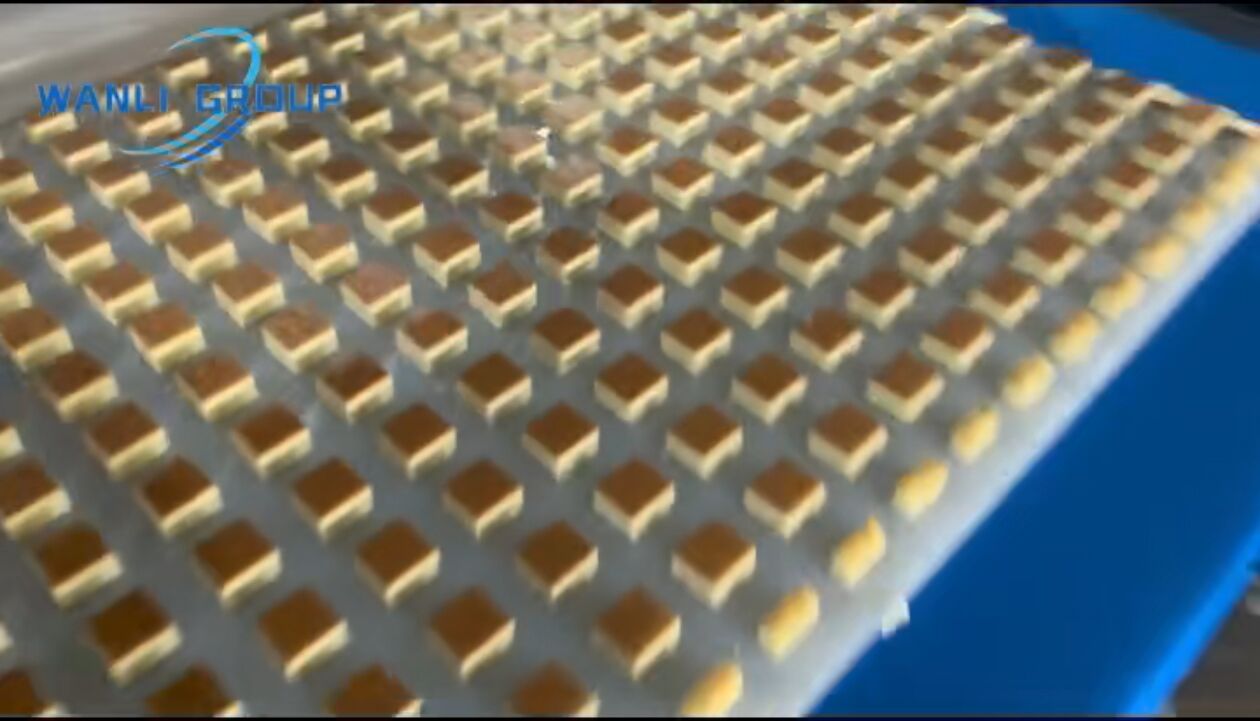

Ultrasonic cutting utilizes high-frequency (above 20 kHz) mechanical vibrations, enabling the cutting tool to create extremely fine cuts within microseconds. This process generates almost no indentation or adhesion, making it particularly suitable for sticky, soft, or frozen foods like cream cakes, Swiss rolls, and chocolate. Compared to traditional blades, ultrasonic cutters have low frictional resistance, producing smooth, crumb-free cuts that significantly reduce product breakage rates and secondary cleaning costs. Furthermore, the ultrasonic energy momentarily softens the local material during cutting, avoiding deformation caused by excessive pressure, ensuring consistent appearance and intact texture for every cake piece.

Core Advantages of Wanli Ultrasonic Cake Cutting Machine

1. Intelligent Control System

The Wanli Ultrasonic Cake Cutting Machine is equipped with a PLC and touchscreen interface. Users can quickly set cutting patterns (round, slice, rectangle, triangle, etc.), speed, and angle through the graphical menu. The system features automatic positioning and size detection, enabling real-time cutting path correction on the production line to ensure precise dimensions for every cake piece.

2. Simple Operation

Simply select the desired cutting shape on the touchscreen, and the machine automatically completes the entire process of feeding, positioning, cutting, and discharging. Even first-time operators can become proficient within minutes, requiring no on-site debugging by specialized technicians.

3. Easy Maintenance

The ultrasonic transducer and cutting tool employ a modular design. Routine cleaning only requires detaching the tool for rinsing. The transducer body features a self-check function, allowing quick fault location and part replacement to minimize downtime. The compact machine footprint, only 3.5 m × 0.9 m, facilitates flexible layout in production facilities of various scales.

4. High Efficiency and Reliability

The Wanli Ultrasonic Cake Cutting Machine incorporates a built-in 5000 W ultrasonic generator, combined with servo motor drive, achieving a cutting speed of up to 60 cycles per minute, meeting high-volume production demands. Constructed from stainless steel and titanium alloy materials, it offers corrosion resistance and long service life. The machine has passed multiple international quality certifications and is highly regarded by customers in markets including Europe, America, and Southeast Asia.

5. Comprehensive Safety Protection

Equipped with safety fencing and photoelectric protection devices, the system automatically stops if an operator mistakenly enters the cutting area, ensuring safe and reliable operation.

Application Scenarios

· Commercial Baking Chains: Standardizes slice specifications, improves product consistency, and enhances brand image.

· Large-Scale Cake Factories: High-speed automated cutting significantly reduces labor costs and increases production capacity.

· Frozen Dessert Production: Low-temperature ultrasonic cutting prevents thawing, maintaining product texture and structure.

Why Choose Wanli

Zhangzhou Wanli possesses over 20 years of experience in baking machinery R&D and has established a comprehensive global after-sales service network. The company adheres to the principle of "Quality First, Reputation First," implementing strict quality management throughout the entire chain of R&D, production, and service. Products are exported to numerous countries and regions, including Europe, America, and Southeast Asia, earning trust from international buyers. Wanli provides customers with one-stop services, from solution design and equipment customization to on-site commissioning, training, and maintenance.

Conclusion

With advanced ultrasonic cutting technology, an intelligent human-machine interface, and a design philosophy emphasizing easy maintenance, the Wanli Ultrasonic Cake Cutting Machine has become the ideal choice for enhancing baking production efficiency and ensuring product quality. We look forward to collaborating with global partners to jointly promote the intelligent upgrade of the baking industry.

Frequently Asked Questions (FAQ)

Q1: What types of food can the ultrasonic cutter cut?

A: It is suitable for sticky or fragile foods like cakes, bread, Swiss rolls, chocolate, cheese, and frozen desserts, producing smooth, non-stick cuts.

Q2: What is the cutting accuracy of the equipment?

A: Utilizing PLC automatic positioning, the cutting dimension error can be controlled within ±0.2 mm, meeting the strict requirements of high-end baking products.

Q3: How is the machine maintenance scheduled?

A: Daily cleaning only requires detaching and rinsing the cutting tool; ultrasonic transducer calibration is recommended every 6 months; spare parts for key components (e.g., servo motor, PLC) are available for on-site replacement.

Q4: Does it support customized cutting patterns?

A: Yes, based on customer-provided CAD drawings or cutting templates, we can customize simultaneous multi-blade cutting or special shape cutting to achieve personalized product requirements.

Q5: What are the power requirements and power consumption of the equipment?

A: The standard model uses a 220 V, 50 Hz power supply, with a power rating of approximately 5000 W, equipped with an efficient cooling system for stable operation.

Q6: How is the after-sales service guaranteed?

A: Wanli has technical service centers globally, providing 24-hour remote diagnostics, on-site repairs, and one year of free maintenance to ensure long-term, efficient equipment operation.

Hot News

Hot News2025-12-14

2025-12-13

2025-12-12

2025-12-11

2025-12-10

2025-12-08