Contact Info

Unit 1011, Pingning Industrial, Longhai District, Zhangzhou City, Fujian Province

New York.

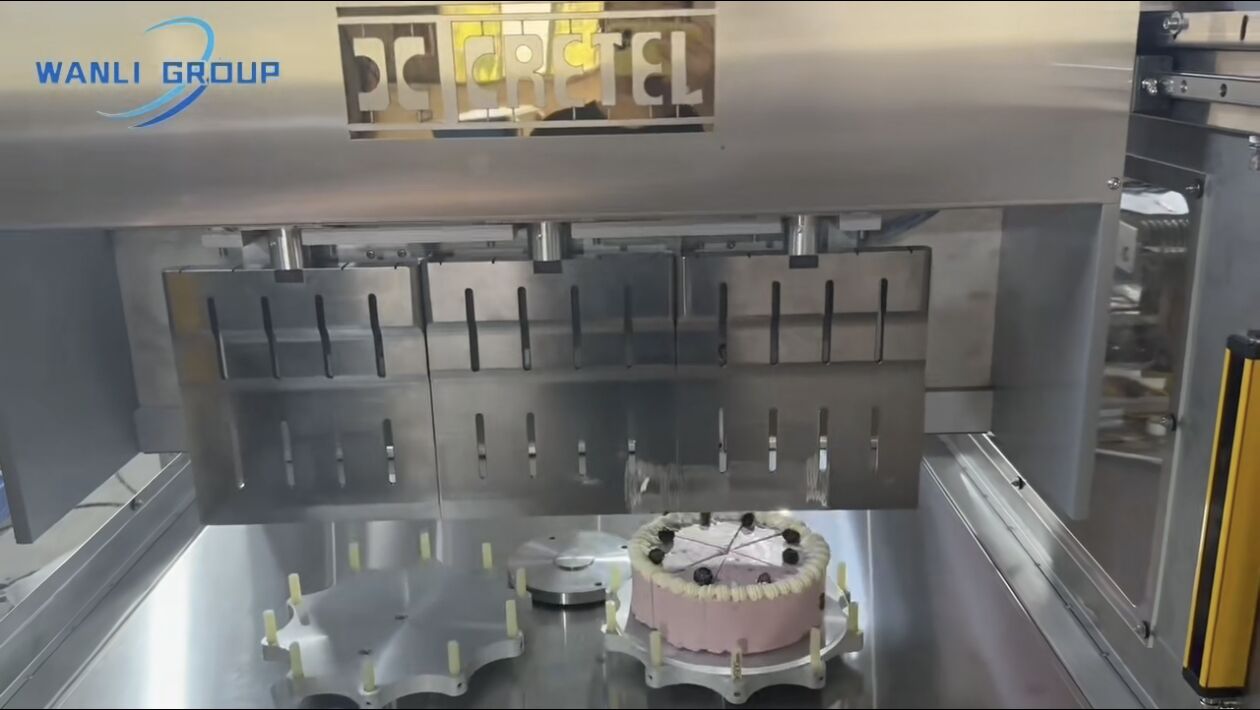

In the global frozen food processing sector, precision cutting of frozen cakes represents a critical production phase that directly impacts product quality and economic returns. Leveraging proprietary ultrasonic cutting technology, our latest Wanli Ultrasonic Frozen Cake Cutting System delivers intelligent solutions for international food manufacturers.

Advanced Ultrasonic Cutting Technology

Ultrasonic cutting technology operates on the principle of converting electrical energy into high-frequency mechanical vibrations for precise material separation. The system's ultrasonic generator transforms standard 50/60Hz current into 20-40kHz high-frequency electrical energy, which is then converted into mechanical vibrations through a transducer and transmitted to the cutting tool, creating microscopic vibrations at tens of thousands of cycles per second. This vibration generates instantaneous energy through molecular friction, enabling clean low-temperature cutting.

Key advantages over conventional cutting methods include:

· Zero-Pressure Cutting: Eliminates product damage while maintaining structural integrity.

· Cold Cutting Process: Prevents heat accumulation to preserve flavor and nutritional value.

· Automatic Edge Sealing: Simultaneously seals cut surfaces to prevent filling leakage.

Technical Excellence of Wanli Ultrasonic Cutting System

Intelligent Control System

· Multi-Axis Motion Control: Integrated PLC and servo systems enable complex cutting patterns.

· Vision Positioning System: High-precision cameras ensure accurate cutting alignment.

· Parameter Memory: Stores multiple process configurations for quick product changeover.

User-Centric Design

· Interactive Interface: 7-10 inch color touchscreen with intuitive graphical controls.

· Smart Monitoring: Built-in diagnostics with real-time operational status tracking.

· Multilingual Support: Interface available in multiple languages for global operations.

Maintenance Efficiency

· Modular Components: Standardized parts for easy service and replacement.

· Automated Cleaning: Self-cleaning mechanism meeting food safety standards.

· Reduced Downtime: High-quality components ensure sustained performance.

Wanli Group Technical Advantages

Wanli Ultrasonic Frozen Cake Cutting System delivers exceptional performance:

· Precision Engineering: ±0.2mm cutting accuracy meets premium market requirements.

· High Throughput: 1,000-1,500 portions per hour capacity.

· Material Efficiency: 99% product integrity rate minimizes waste.

The system accommodates various frozen cake types including mousse cakes, cream-filled varieties, and cheesecakes, demonstrating excellent material adaptability.

Frequently Asked Questions

1. What specific product types is the equipment suitable for?

The Wanli Ultrasonic Frozen Cake Cutting Machine suits most frozen cake products, including multi-layer mousse cakes, filled cakes, and cheesecakes, showing excellent adaptability to products with varying fat contents and textures.

2. Is the production specification changeover process complex?

Using the smart memory system, the equipment completes specification changes within 2-3 minutes, supporting up to 20 preset parameter groups, greatly enhancing production flexibility.

3. What does routine maintenance primarily include?

Routine maintenance mainly involves blade cleaning, transmission system inspection, and regular servicing. The modular design enables most maintenance to be completed within 30 minutes, significantly reducing downtime.

4. What are the production environment requirements?

Recommended operation in environments of 0-25°C with humidity ≤85%, requiring stable power and air sources. Specific requirements can be customized according to client conditions.

5. Can custom cutting shapes and sizes be accommodated?

Various custom requirements are supported, including special cutting shapes, dimensions, and capacity configurations. Our engineering team provides professional technical consultation and sampling services.

6. How long does operator training require?

Basic operation training takes approximately 4 hours, advanced maintenance training about 8 hours. We provide detailed manuals and video tutorials to ensure rapid proficiency.

7. What is the after-sales service response mechanism?

Our global service network ensures 24-hour domestic response and 48-hour international technical support, maintaining continuous client production.

Wanli Machinery is committed to providing innovative technical solutions for the global food industry. The Wanli Ultrasonic Frozen Cake Cutting Machine represents our latest achievement in ultrasonic cutting technology. We look forward to establishing long-term partnerships with global clients to jointly advance technological progress in the baking sector.

Hot News

Hot News2025-12-14

2025-12-13

2025-12-12

2025-12-11

2025-12-10

2025-12-08