ԿՈՆՏԱԿՏԱՅԻՆ ՏԵՂԵԿՈՒԹՅՈՒՆՆԵՐ

Միավոր 1011, Պինգնինգ ឧստրիալ, Լոնգհաի RICT, Չանգչուու քաղաք, Ֆուջիան մարզ

Նույն Յորք.

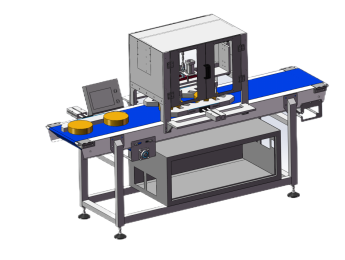

Վանլիսոնիկ Ավտոմատացված Մաքսի Կերական Սահքի Կատարող Ռոբոտ Հավասարակշռված Դատարկման Ֆունկցիայի Հետ նորացնում է սառկող գույնի պատրաստումը իր ավանդական տեխնոլոգիայի միջոցով։ Դիզայնավորված հատուկ սառկող մուսային քաղցիների համար, այս նորագույն համակարգը ժամանակակից հուլտրասոն ճշգրտությամբ համատեղ կտրում է երեք կլոր ստորագրություն (կարգավորելի 50-150 մմ տրամագիծ)՝ պահպանելով mooieն սառկող տեքստուրաների ամենակարևոր մանրամասները։ Հիմնված բարձր հաճախականության հուլտրասոն կոտորակների վրա, այն ապահովում է կարևոր և անգույն կտրում։ Առավելագույնությամբ ինքնակարգավոր ստորականացման տեխնոլոգիայի միջոցով, համակարգը ավտոմատ ձեռնարկում է կոտորակներից մնացորդ արտադրանքները կտրում ցիկլերի միջև՝ ապահովելով համապատասխան հիգիենային պայմաններ և անջատելով կրոս-կամարտությունը։ Երկարական հիգիենային ստանդարտներին համապատասխան համատեսական արտադրանքից կառուցված համակարգը իдеալ է արտադրանքային հացանոցների և սառկող արտադրանքների համար։ Կոտորակների, արագության և հիգիենայի միացումով, Wanlisonic փոխում է աշխատանքային ձեռնարկման գործընթացը ավտոմատացված գործընթաց։ Իդեալ է շոկոլադի, միրգին կամ միրգային գլազիրով մուսային քաղցիների համար, այս մեքենան ավելացնում է արդյունավետությունը՝ պահպանելով գեղարվեստական պատիսերի արվեստը։

★Միջին արագություն՝ 45 կտրումներ արժանիկ .

★T ekran ուժեղ օգտագործողին հարմար chnittaran .

★Ավարտ և կարող սկզբնական աղեղ .

★Ավելացված որոշումը և աշխատանք խանգիտությունը դարձնում են ավելի լավ հատուկությունը .

★Հասնելի մաս որոշումը և համապատասխանություն

Ապրանքի մանրամասների ցուցադրում

|

|

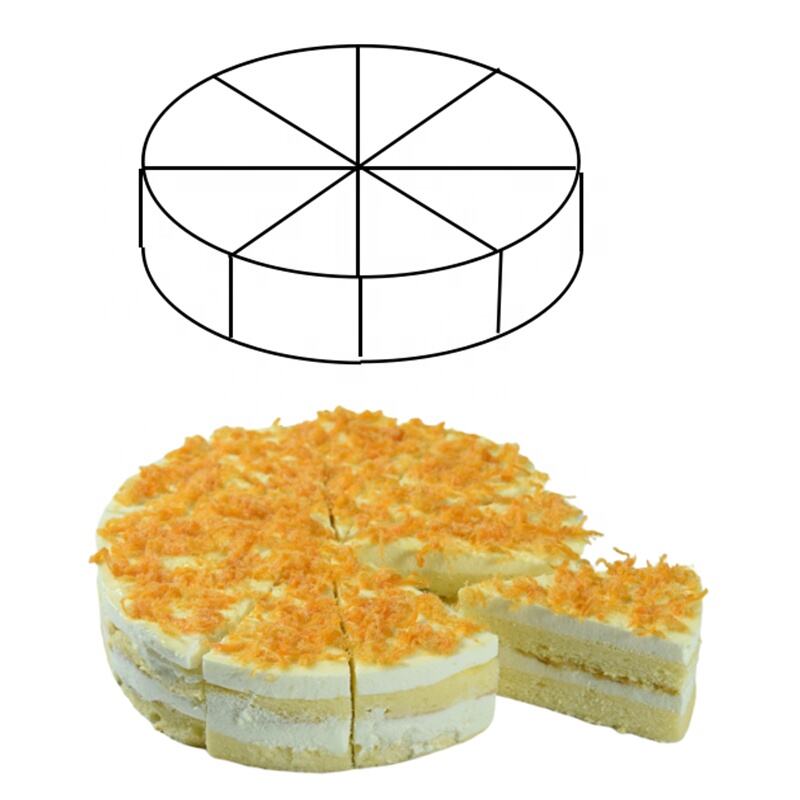

| Կտրման โրդ & Օրինակ կտրելու |

|

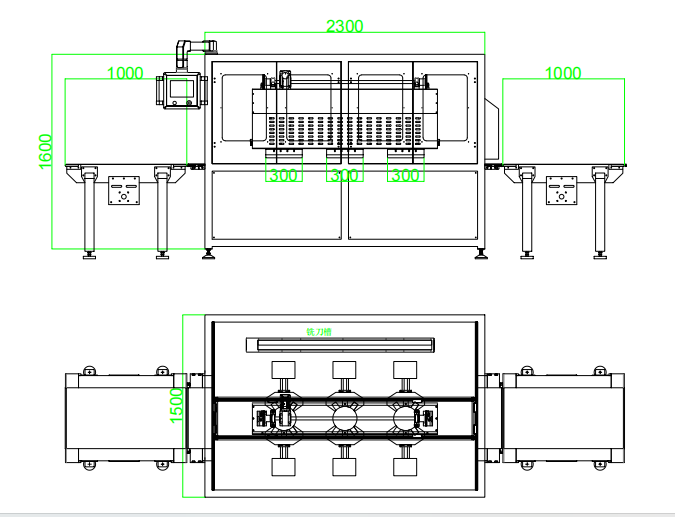

| Characteristics | Սարքի չափերը (Ե x Ծ x Բ) |

• Կամար անոթափոխ կառուցվածք և բաժակատար պլաստմասներ |

|

Ապարատի Նկարագրություն

Ոչ, ես չեմ ուզում: |

Անվանումը բաղադրիչի |

Բրենդ |

Ներածություն |

Նկարի |

1 |

Ալտրասոնային կոտորակ |

Պատվերական |

Artículo պատրաստված է Տիտանի Համադրությունից, որի մեխանիկական ուժը ավելի լավ է, քան անգամից, ձայնափոխությունը լավ է, ձայնահաճախությունը չի ստորագում ներքին փոխանցման ժամանակ, ունի ուժեղ թթվաբարության կորոզիայի կարողություն |

|

2 |

Կտրելու մաքնինային կառուցվածքը սովորականից ավելի հաստ և մեծ |

Wanlisonic |

Լիցքավոր ստալենական, հեշտ է կլանել, սովորականից ավելի հաստ չինական նորմատիվ նյութերով կառուցված, Anshan Iron and Steel Company-ի կողմից ստեղծված |

|

3 |

Էներգիայի փոխակերպիչ |

Wanlisonic |

Էլեկտրաէներգիան փոխակերպվում է կինետիկ էներգիայի, որպեսզի կատարդի արտադրանքները |

|

4 |

Փոխակրիչ |

Wanlisonic |

Եկամուտային մակարդակի տրանսպորտատորի շղթա |

|

5 |

Հասանելի էկրան |

Դելտա |

Ինտելեկտուալ կառավարում, համակարգի գործողությունների և մոնիտորինգի համար |

|

6 |

PLC Կառավարման Համակարգ |

Դելտա |

Սխալների կանգնացում, ապահովության թեստավորում, ալարմի ցույց |

|

7 |

Ռելե |

Օմրոն |

Տաք կանցնիչ |

|

8 |

Սենսոր |

Leuze |

Արտադրանքների առկայության թեստավորում կատարդիչի տակ |

|

9 |

Շրջանառության փոխարկիչ |

ՍԱՆՋԻՆԳ կամ Delta |

Debeqneri dpiranq toxel |

|

10 |

Սերվո շարժիչ |

Դելտա |

Kilichneri dpiranq toxel |

|

11 |

Stepmotor |

Դոռնա |

Kilichneri dpiranq toxel |

|