Modern ready-meal production lines face constant pressure to increase output while maintaining consistent product quality. Traditional cutting methods often struggle with the demanding pace and precision required in high-volume food manufacturing environments. An ultrasonic sandwich cutter represents a revolutionary advancement in food processing technology, utilizing high-frequency vibrations to slice through various sandwich compositions with remarkable speed and accuracy. This cutting-edge equipment has transformed how manufacturers approach sandwich production, enabling them to meet growing consumer demand while reducing operational costs and minimizing product waste.

Understanding Ultrasonic Cutting Technology

The Science Behind Ultrasonic Vibrations

Ultrasonic cutting technology operates on the principle of high-frequency mechanical vibrations, typically ranging from 20,000 to 40,000 cycles per second. When an ultrasonic sandwich cutter blade vibrates at these frequencies, it creates microscopic oscillations that effectively reduce friction between the cutting surface and food materials. This phenomenon allows the blade to slice through even the most challenging sandwich components without dragging or compressing the ingredients. The ultrasonic energy creates a temporary separation at the molecular level, enabling clean cuts through soft breads, delicate vegetables, and sticky fillings that would otherwise deform under conventional cutting pressure.

The ultrasonic waves generate localized heating effects that can slightly warm the cutting interface, further reducing resistance when processing temperature-sensitive ingredients. This controlled thermal effect ensures that frozen or chilled sandwich components maintain their structural integrity during the cutting process. Food manufacturers benefit from this technology because it eliminates the need for excessive downward pressure, which often causes ingredient displacement and aesthetic defects in finished products.

Blade Design and Material Considerations

The effectiveness of an ultrasonic sandwich cutter depends heavily on specialized blade construction designed to transmit and amplify vibrational energy. These blades typically feature titanium or high-grade stainless steel compositions that can withstand continuous ultrasonic stress without degradation. The blade geometry includes precisely calculated horn shapes and amplitude patterns that optimize energy transfer throughout the cutting edge. Manufacturing engineers carefully tune blade resonance frequencies to match the ultrasonic generator output, ensuring maximum cutting efficiency.

Surface treatments and coatings further enhance blade performance by reducing food adhesion and improving hygiene standards. Non-stick coatings specifically formulated for food contact surfaces help maintain consistent cutting performance throughout extended production runs. The blade assembly includes sophisticated mounting systems that isolate vibrations from surrounding machinery while ensuring precise alignment and stability during high-speed operations.

Speed Advantages in Ready-Meal Production

Increased Throughput Capabilities

Ready-meal production facilities implementing an ultrasonic sandwich cutter typically experience throughput increases of 30 to 50 percent compared to conventional cutting methods. The reduced cutting resistance allows machinery to operate at higher linear speeds without compromising cut quality or causing product damage. This speed enhancement directly translates to increased production capacity, enabling manufacturers to process larger order volumes without additional labor or extended operating hours. The consistent cutting performance eliminates the need for frequent stops to clean blades or adjust cutting parameters, maintaining continuous production flow.

High-volume operations particularly benefit from the ability to maintain cutting speed regardless of sandwich composition complexity. Traditional cutting systems often require speed reductions when processing sandwiches containing multiple layers, sticky sauces, or hard ingredients like nuts or seeds. An ultrasonic sandwich cutter maintains consistent performance across diverse product formulations, allowing production schedulers to optimize line efficiency without accounting for product-specific speed variations. This reliability enables manufacturers to commit to tighter delivery schedules and respond more effectively to market demand fluctuations.

Reduced Downtime and Maintenance Requirements

The self-cleaning action inherent in ultrasonic cutting significantly reduces maintenance-related production interruptions. Traditional blade systems accumulate food residue and require frequent cleaning cycles that halt production and consume valuable operational time. The vibrational energy of an ultrasonic sandwich cutter prevents most food particles from adhering to cutting surfaces, extending the intervals between mandatory cleaning procedures. This extended operational time directly contributes to improved overall equipment effectiveness and higher daily production totals.

Predictive maintenance programs become more effective with ultrasonic cutting systems because wear patterns are more consistent and predictable. The reduced mechanical stress on cutting components extends blade life and decreases replacement frequency. Maintenance teams can schedule servicing activities during planned downtime rather than responding to unexpected equipment failures. The improved reliability reduces the need for backup equipment and allows manufacturers to operate with leaner maintenance inventories while maintaining production consistency.

Quality Enhancement Through Precision Cutting

Consistent Portion Control

Precision portion control becomes achievable with ultrasonic sandwich cutter technology because the consistent cutting force eliminates variability introduced by ingredient resistance. Traditional cutting methods often produce portions that vary in weight and dimensions due to ingredient compression and blade deflection under varying loads. The ultrasonic cutting process maintains dimensional accuracy regardless of sandwich density or filling distribution, ensuring that each portion meets predetermined specifications. This consistency reduces product giveaway costs and helps manufacturers maintain profit margins while meeting consumer expectations for uniform portions.

Automated portion control systems integrate seamlessly with ultrasonic cutting technology, enabling real-time weight monitoring and adjustment capabilities. The precise cutting action allows for tighter tolerances in portion specifications, reducing the safety margins typically required to accommodate cutting variability. Food manufacturers can optimize recipe formulations and packaging designs around more predictable portion dimensions, leading to improved supply chain efficiency and reduced packaging waste.

Preservation of Product Integrity

The gentle cutting action of an ultrasonic sandwich cutter preserves the visual appeal and structural integrity of delicate sandwich ingredients that might be damaged by conventional cutting methods. Soft breads maintain their texture without compression, while fillings remain properly distributed rather than being squeezed out during the cutting process. This preservation of product appearance directly impacts consumer perception and purchase decisions, particularly in retail environments where visual presentation influences buying behavior.

Temperature-sensitive ingredients benefit from the minimal heat generation associated with ultrasonic cutting, preventing thermal damage that could affect taste, texture, or nutritional content. Cheese layers remain properly positioned, vegetables retain their crispness, and sauces maintain their intended consistency throughout the cutting operation. The improved product integrity reduces customer complaints and returns while supporting premium pricing strategies for high-quality ready-meal products.

Energy Efficiency and Cost Considerations

Power Consumption Analysis

Despite the sophisticated technology involved, an ultrasonic sandwich cutter typically consumes less energy than comparable conventional cutting systems when evaluated on a per-unit production basis. The reduced cutting resistance decreases motor loads and allows drive systems to operate more efficiently. Energy consumption remains relatively constant regardless of sandwich composition, eliminating the power spikes and variations common with mechanical cutting systems encountering difficult materials. This predictable energy usage helps manufacturers better forecast operating costs and optimize production scheduling around peak demand periods.

The elimination of hydraulic or pneumatic assist mechanisms further reduces energy requirements while simplifying utility connections and reducing installation complexity. Modern ultrasonic generators incorporate advanced power management systems that automatically adjust output based on cutting demands, minimizing energy waste during idle periods or light production runs. These efficiency improvements contribute to reduced carbon footprints and support sustainability initiatives increasingly important to food manufacturers and their customers.

Return on Investment Calculations

Investment recovery periods for ultrasonic sandwich cutter installations typically range from 18 to 36 months, depending on production volumes and labor cost structures. The primary cost savings derive from increased throughput, reduced labor requirements, and decreased product waste rather than just equipment operational savings. Higher production speeds enable manufacturers to fulfill larger contracts with existing equipment capacity, deferring or eliminating the need for additional production lines. The improved product consistency reduces quality control labor and rework costs while minimizing customer returns and warranty claims.

Long-term financial benefits extend beyond direct operational savings to include improved market positioning through enhanced product quality and reliability. Manufacturers can pursue premium market segments that demand consistent portion sizes and superior product presentation. The ability to handle diverse product formulations without equipment changes enables more flexible production planning and faster response to market opportunities. These strategic advantages often provide returns that exceed the direct operational cost savings used in initial investment justifications.

Integration with Existing Production Lines

Retrofit Compatibility Options

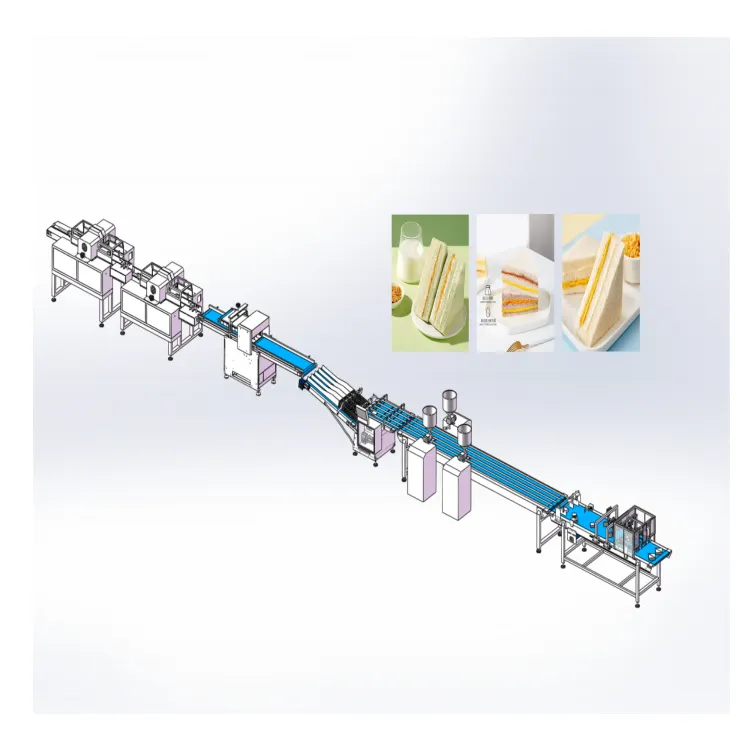

Most existing ready-meal production lines can accommodate ultrasonic sandwich cutter installations with minimal structural modifications or disruption to adjacent processes. The compact design of modern ultrasonic cutting systems allows integration into tight spaces where traditional cutting equipment might require extensive facility modifications. Modular mounting systems facilitate installation while maintaining access for maintenance and cleaning procedures. The standardized interfaces and communication protocols enable integration with existing control systems and production management software without extensive programming modifications.

Retrofit projects benefit from the ability to maintain existing conveyor systems and upstream preparation equipment while upgrading only the cutting function. This selective modernization approach allows manufacturers to realize immediate benefits from ultrasonic cutting technology without the expense and disruption of complete line reconstruction. The improved cutting performance often creates capacity increases that benefit the entire production line, maximizing return on the retrofit investment through enhanced overall system productivity.

Automation and Control Integration

Advanced ultrasonic sandwich cutter systems integrate seamlessly with automated production control systems, enabling remote monitoring and adjustment of cutting parameters. Real-time feedback systems monitor cutting performance and automatically compensate for variations in product characteristics or environmental conditions. Integration with upstream systems allows cutting parameters to be automatically adjusted based on product formulation data, ensuring optimal performance across diverse sandwich recipes without manual intervention. These automated capabilities reduce operator skill requirements while maintaining consistent cutting quality throughout production runs.

Data logging and analysis capabilities provide valuable insights into production efficiency and quality trends that support continuous improvement initiatives. Integration with enterprise resource planning systems enables real-time production tracking and inventory management based on actual cutting performance rather than theoretical calculations. The detailed performance data supports predictive maintenance programs and helps optimize production scheduling to maximize equipment utilization and minimize operational costs.

Food Safety and Hygiene Benefits

Contamination Prevention Features

The design characteristics of an ultrasonic sandwich cutter inherently support improved food safety standards through reduced contamination risks and enhanced cleaning effectiveness. The vibrating blade surface prevents bacterial adhesion and biofilm formation that commonly occur on stationary cutting surfaces in traditional systems. The reduced need for cutting lubricants eliminates potential contamination sources while simplifying cleaning procedures and reducing chemical usage. Smooth surface finishes and minimal crevices in ultrasonic cutting assemblies facilitate thorough sanitization and inspection procedures.

The elimination of cutting force variability reduces the risk of product cross-contamination that can occur when ingredients are compressed and displaced during cutting. Clean separation of sandwich components prevents filling migration that could introduce allergens or other contaminants into adjacent products. The consistent cutting action maintains ingredient placement accuracy, supporting allergen control programs and traceability requirements increasingly important in ready-meal production facilities.

Cleaning and Sanitization Efficiency

Cleaning cycles for ultrasonic cutting systems typically require 40 to 60 percent less time than conventional cutting equipment due to the self-cleaning action of the vibrating surfaces. The reduced cleaning frequency and duration decrease chemical consumption and water usage while minimizing production interruptions for sanitation procedures. Automated cleaning systems can be more effectively implemented with ultrasonic cutting technology because the predictable soil loading patterns enable optimized cleaning programs that ensure thorough sanitization without excessive chemical usage or cycle times.

The improved cleaning effectiveness supports more stringent food safety standards and enables manufacturers to pursue certifications that require enhanced hygiene protocols. The reduced cleaning labor requirements free personnel for other value-added activities while ensuring consistent sanitation standards throughout production operations. These hygiene improvements reduce the risk of product recalls and regulatory violations that could significantly impact business operations and brand reputation in competitive ready-meal markets.

FAQ

What maintenance is required for ultrasonic sandwich cutting equipment

Ultrasonic sandwich cutting equipment requires routine maintenance focused primarily on ultrasonic generator calibration, blade inspection, and cleaning system verification. Daily maintenance typically involves visual inspection of cutting surfaces and verification of ultrasonic frequency output through built-in diagnostic systems. Weekly procedures include thorough cleaning of all food contact surfaces and inspection of blade mounting assemblies for wear or damage. Monthly maintenance encompasses generator performance testing, vibration analysis, and replacement of consumable components such as gaskets and filters. Annual servicing includes comprehensive calibration of ultrasonic parameters, replacement of wear items, and updating control software as needed.

How does cutting speed compare between ultrasonic and traditional methods

Ultrasonic sandwich cutting systems typically operate 30 to 50 percent faster than traditional mechanical cutting methods when processing similar product volumes. The consistent cutting force enables higher linear speeds without quality degradation, while traditional systems must reduce speed when encountering difficult ingredients or complex sandwich formulations. Ultrasonic systems maintain steady cutting rates regardless of product composition, eliminating the speed variations that reduce overall throughput in conventional systems. The reduced maintenance downtime and cleaning requirements further contribute to higher effective production speeds throughout typical operating shifts.

What types of sandwich products work best with ultrasonic cutting

Ultrasonic cutting technology performs exceptionally well with multi-layer sandwiches containing soft breads, delicate vegetables, sticky sauces, and temperature-sensitive fillings that challenge traditional cutting methods. Products with frozen or chilled components benefit particularly from the reduced cutting force that prevents ingredient damage during processing. Sandwiches containing nuts, seeds, or other hard inclusions that typically cause blade wear in conventional systems process smoothly with ultrasonic technology. The versatility of ultrasonic cutting enables processing of diverse product formulations without equipment adjustments, making it ideal for facilities producing multiple sandwich varieties on the same production line.

What are the power requirements for ultrasonic cutting systems

Typical ultrasonic sandwich cutting systems require 220-480V electrical service with power consumption ranging from 2 to 8 kW depending on cutting capacity and system configuration. The power requirements remain relatively constant regardless of product difficulty, unlike traditional systems that experience significant power variations based on cutting resistance. Most installations require only standard industrial electrical connections without specialized power conditioning equipment. The predictable power consumption facilitates accurate cost calculations and enables integration with energy management systems for optimal operational efficiency. Backup power systems can be sized appropriately based on consistent power draw characteristics rather than peak demand scenarios common with conventional cutting equipment.