Contact Info

Unit 1011, Pingning Industrial, Longhai District, Zhangzhou City, Fujian Province

New York.

Introduction to Ultrasonic Cutting Technology

Ultrasonic cutting represents a significant leap forward in food processing technology. Unlike traditional blades that rely on brute force, ultrasonic cutters utilize high-frequency vibrations (typically 20kHz to 40kHz) to perform clean, precise cuts. This technology offers unparalleled advantages for bakery products, especially delicate items like cakes. The high-frequency vibrations minimize friction and pressure, effectively sealing the edges of the product as it cuts. This results in crumb-free slices, perfect shapes, and significantly extended blade life due to reduced wear and tear. For products with sticky fillings or soft textures, ultrasonic cutting eliminates the common problems of sticking, deformation, and ragged edges.

Technical Advantages of Wanlisonic Equipment

The core advantage of Wanlisonic equipment lies in its advanced ultrasonic generator and cutting blade design. Our generators maintain stable frequency output even under fluctuating voltage conditions, ensuring consistent cutting performance. The titanium alloy cutting blades are manufactured to withstand continuous high-frequency vibrations while maintaining structural integrity. This robust engineering translates to reliable operation in high-volume production environments where equipment durability is paramount.

Introducing the Wanlisonic Intelligent Square Cake Cutting Machine

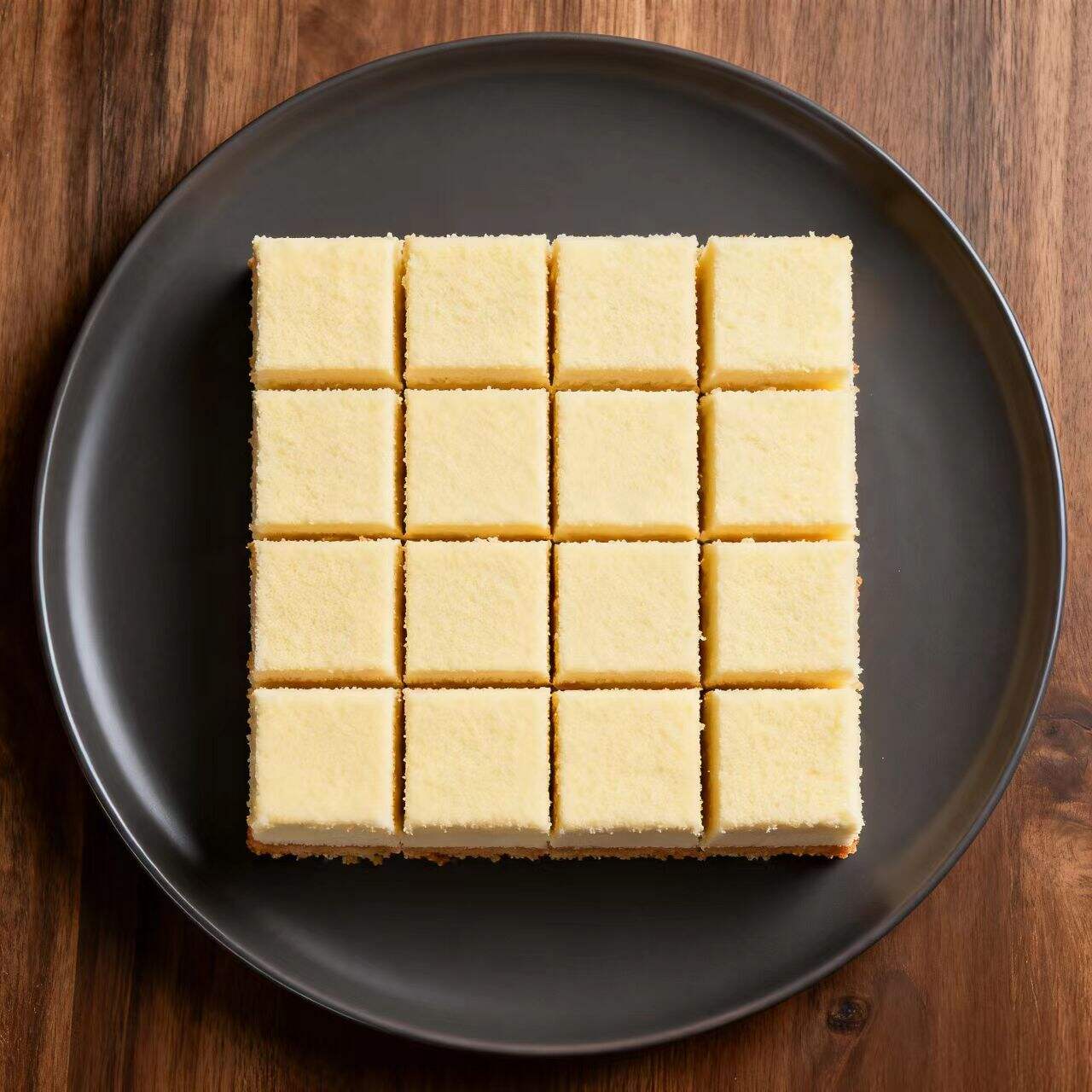

The Wanlisonic Intelligent Square Cake Cutting Machine is engineered specifically for high-volume production lines requiring consistent, high-quality results on square or rectangular cake products.

Key Features and Benefits:

1. Intelligent Design & User-Friendly Operation: The machine incorporates a sophisticated industrial-grade PLC (Programmable Logic Controller) and features a 10-inch high-resolution HMI (Human-Machine Interface) touchscreen. Operators can easily set parameters such as cutting dimensions (with precision up to 0.1mm), production speed (adjustable from 10-60 cycles per minute), and cutting quantity with just a few taps. The system allows for storing up to 50 different product recipes, enabling quick changeover between production batches. The intuitive graphical interface displays real-time operational data including production counts, maintenance reminders, and error diagnostics, minimizing training time and reducing the potential for human error.

2. Exceptional Ease of Maintenance: We understand that downtime directly impacts profitability. The Wanli square cake cutter features a modular design with quick-disconnect components for easy access. The main cutting module can be detached within minutes for thorough cleaning or maintenance. The ultrasonic transducer system is equipped with automatic frequency tracking and overload protection, preventing damage during operation. Routine maintenance primarily involves basic cleaning and visual inspections, which can be efficiently performed by regular production staff following our comprehensive maintenance guidelines.

3. Superior Cutting Quality: By harnessing Wanlisonic ultrasonic technology, this machine delivers flawless cuts consistently. The high-frequency vibrations (20kHz or 35kHz options available) create micro-oscillations that cleanly slice through cakes with delicate layers, sticky icings, or soft crumb structures without compressing the product. The non-thermal cutting process preserves product integrity and freshness. The result is perfectly portioned slices with smooth, sealed edges that enhance visual appeal and extend shelf life by reducing moisture loss and contamination risk.

Industry Applications and Versatility

Beyond standard square cakes, this versatile machine accommodates various product types including layered cream cakes, cheesecakes, brownies, and dense pastry products. The adjustable cutting parameters allow processors to handle products with different densities and textures without compromising cutting quality. For specialized applications, Wanli Machinery offers custom blade configurations and conveyor modifications to meet specific production requirements.

Why Choose Zhangzhou Wanli?

Choosing Wanli Machinery means investing in a comprehensive partnership. We provide end-to-end support including:

• Pre-sales technical consultation and production analysis

• Customized solution design and factory layout planning

• Professional installation and commissioning services

• Comprehensive operator and maintenance training programs

• Ongoing technical support and spare parts supply

Visit our website at http://wanlimachinery.com to explore our complete range of ultrasonic cutting solutions. Contact our technical team for a free production assessment and discover how our square cake cutting machine can transform your bakery operations.

Frequently Asked Questions

Q1: What types of products are suitable for the Wanlisonic Square Cake Cutting Machine?

A: This machine is ideal for cutting a wide variety of square or rectangular bakery products, including sponge cakes, sheet cakes, layered cakes with creams or jellies, brownies, and fudge. It excels with products that are difficult to cut cleanly using traditional methods.

Q2: How does the intelligent control system improve operation?

A: The PLC and HMI system allows for precise di

Q2: How does the intelligent control system improve operation?

A: The PLC and HMI system allows for precise digital control over all cutting parameters. Recipes can be saved and recalled instantly, ensuring consistency across different batches and operators. The system can also provide diagnostic information, simplifying troubleshooting.

Q3: Is the machine difficult to maintain for our factory staff?

A: Not at all. The machine is designed for ease of maintenance. Wanli provides detailed operation and maintenance manuals, and our technical support team is available for guidance. Routine maintenance primarily involves basic cleaning and visual checks, which your staff can quickly learn.

Q4: Can Wanli customize the machine to fit our specific production line layout?

A: Yes, absolutely. As a core strength of Wanli Group, we specialize in providing customized solutions. We can adapt the machine's dimensions, conveyor system, and integration points to seamlessly fit into your existing production line.

Q5: What after-sales support does Zhangzhou Wanli offer?

A: We provide comprehensive after-sales support, including detailed installation guidance (onsite or remote), operator training, a warranty period, and readily available spare parts. Our service team is committed to ensuring your equipment operates optimally.

Q6: What's the typical installation and commissioning timeline?

A: For standard models, installation and commissioning typically take 3-5 working days. For customized solutions, the timeline may vary depending on specific requirements. Our project managers will provide detailed schedule planning during the order process.

Hot News

Hot News2025-12-14

2025-12-13

2025-12-12

2025-12-11

2025-12-10

2025-12-08