Contact Info

Unit 1011, Pingning Industrial, Longhai District, Zhangzhou City, Fujian Province

New York.

Innovative Cutting Solution for Modern Food Production

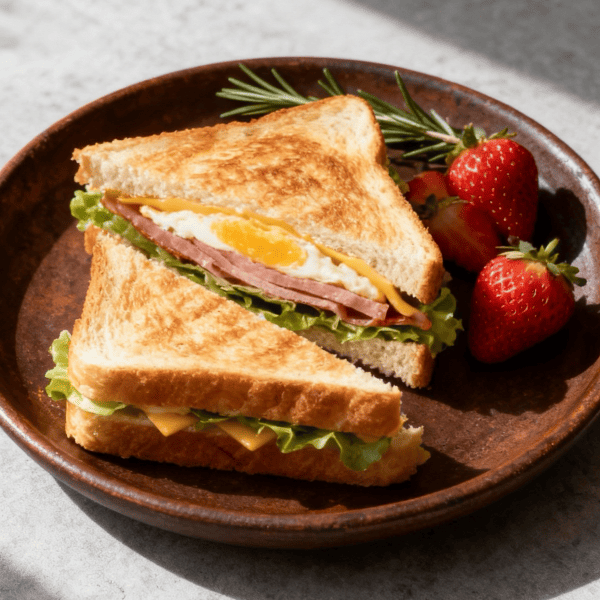

Wanli Machinery introduces revolutionary ultrasonic cutting technology to the sandwich production industry. Our advanced systems utilize high-frequency vibrations to replace traditional cutting methods, delivering perfectly clean cuts without compression or deformation. This innovative approach maintains product integrity and eliminates filling spillage, ensuring consistent portion control and superior product appearance throughout production runs.

Smart Sandwich Cutting Technology

The Zhangzhou Wanli sandwich cutting machine designed specifically for various sandwich types, our equipment features:

Precision Cutting System

Ensures accurate portion control with clean edges and minimal product waste.

Adaptable Configuration

Quick-adjust settings allow rapid switching between different sandwich sizes and specifications.

Integrated Handling

Gentle product transport maintains sandwich structure and presentation quality.

Intelligent Operation and Maintenance

Wanli Group engineers have focused on operational efficiency in every aspect of the design:

User-Friendly Control Interface

Color touchscreen with multi-language support enables simple operation with minimal training requirements.

Automated Monitoring

Self-diagnostic systems alert operators to maintenance needs before issues affect production.

Modular Construction

Quick-access components and easy-clean surfaces simplify maintenance and reduce downtime.

Key Performance Benefits

Wanli machinery delivers significant improvements to production efficiency:

Enhanced Productivity

Automated cutting process increases output capacity while maintaining consistent quality.

Labor Optimization

Reduces manual handling requirements by up to 75%compared to traditional methods.

Quality Consistency

Maintains uniform portion sizes and clean presentation throughout extended production runs.

Technical Specifications

Our sandwich cutting systems accommodate various production requirements:

Production Capacity

Configurable systems available for small-scale operations (800+ pieces/hour) to industrial-scale production (3000+ pieces/hour).

Flexible Adaptation

Customizable cutting patterns accommodate different sandwich sizes and configurations.

Hygienic Design

Food-grade materials and sanitary construction meet international food safety standards.

Comprehensive Support Services

Zhangzhou Wanli provides complete technical support:

Professional Installation

Factory-trained technicians ensure proper setup and operational training.

Ongoing Maintenance

Preventive maintenance programs and remote support minimize operational disruptions

Global Parts Support

Genuine Wanli components available through worldwide logistics network.

Discover Our Technology

Visit wanlimachinery.com for detailed technical specifications and application case studies. Contact our engineering team to discuss your specific production requirements.

Frequently Asked Questions

1. What types of sandwiches are suitable for the Wanli cutting system?

Our equipment handles various sandwich types including breakfast sandwiches, tea sandwiches, club sandwiches, and wrapped sandwiches with consistent results.

2. How does ultrasonic cutting improve sandwich quality?

The vibration-based cutting action prevents compression and deformation while ensuring fillings remain intact within the sandwich structure.

3. What training is provided with equipment purchase?

We offer comprehensive operational training, maintenance procedures, and technical documentation to ensure optimal system performance.

4. Can the machine handle different sandwich sizes?

Yes, our systems feature adjustable parameters to accommodate various product dimensions and configurations.

5. What is the typical maintenance requirement?

Daily cleaning and periodic blade inspection are the primary requirements, with most maintenance procedures requiring minimal downtime.

Hot News

Hot News2025-12-14

2025-12-13

2025-12-12

2025-12-11

2025-12-10

2025-12-08