Contact Info

Unit 1011, Pingning Industrial, Longhai District, Zhangzhou City, Fujian Province

New York.

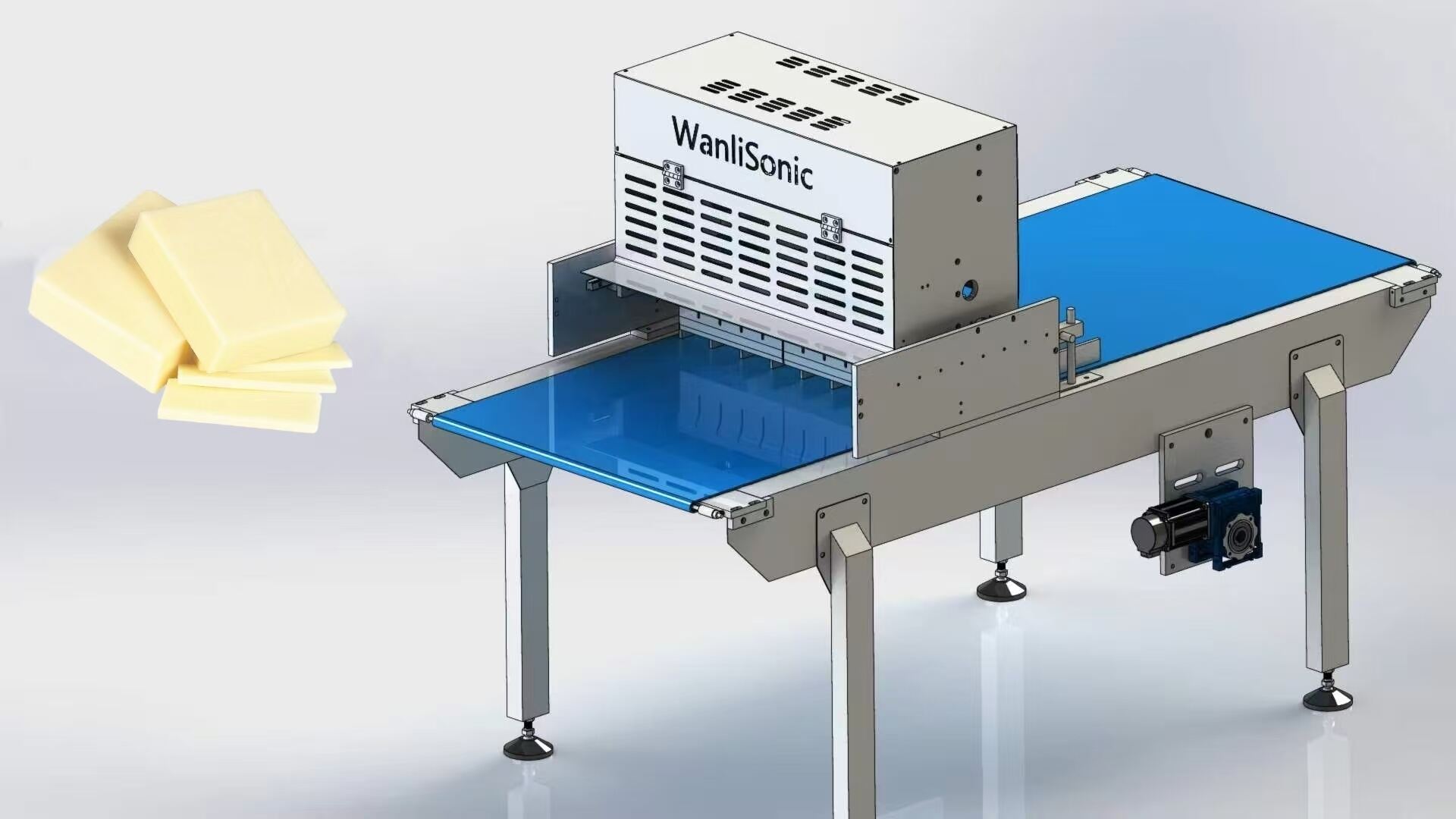

In the dairy and baking industries, achieving efficient, clean slicing of soft cheeses, cream cheese, and various fresh cheeses remains an ongoing production challenge. Traditional blade or wire saw cutting methods are prone to product adhesion, deformation, and crumb generation. This not only compromises product aesthetics and portion consistency but also leads to significant material waste and rising labor costs. Addressing this industry pain point, Zhangzhou Wanli introduces the innovative Wanli Fully Automatic Ultrasonic Cheese Slicer. This equipment is specifically engineered for the precision processing of sticky, soft-textured foods, aiming to provide global food producers with a cutting solution that combines high efficiency, high precision, and exceptional hygiene standards.

Ultrasonic Cutting Technology Farewell to Adhesion, Achieve Pure Cutting

Traditional cutting relies on physical pressure to force a blade through material, which for soft, fat- and moisture-rich cheeses easily causes product adhesion to the blade and structural compression. The ultrasonic cutting technology employed by Wanli Group represents a fundamentally different philosophy of precision cutting.

Its core principle involves converting electrical energy into high-frequency mechanical vibrations (typically 20-40kHz) via an ultrasonic generator, which are transmitted to a special alloy blade. The blade edge consequently produces microscopic vibrations tens of thousands of times per second. Upon contact with the cheese, it does not "press-cut" but uses the energy from high-frequency vibrations to rapidly and locally separate the material at a molecular level. This process delivers three fundamental advantages:

1. Non-Contact Cutting: The vibrating blade generates almost no lateral pulling force, treating the product with utmost gentleness. It perfectly preserves the original soft texture and complete shape of products like cheese and soft bread, preventing collapse or deformation.

2. Eliminates Product Adhesion: High-frequency vibration drastically reduces the coefficient of friction between the blade and the material, fundamentally solving the sticking problem caused by fats and sugars. This ensures each slice separates automatically after cutting, leaving a pristine, clean surface.

3. Elevates Hygiene Standards: The dry cutting process greatly minimizes food residue accumulation on the blade. Combined with the equipment's easy-clean design, it effectively controls microbial growth risks, complying with stringent international food safety regulations.

Intelligent Design Simplifying Complexity, Empowering Efficient Production

The success of the Wanli Fully Automatic Ultrasonic Cheese Slicer stems not only from advanced cutting technology but also from its human-centric intelligent and user-friendly design, allowing sophisticated technology to integrate seamlessly into daily production.

· Intuitive Smart Control Center: The equipment features a user-friendly color touchscreen with a logically clear interface. Staff can easily set parameters like slice thickness, cutting speed, and count. The system supports storage for multiple product recipes, enabling one-touch recall when switching tasks. This significantly reduces adjustment time, minimizes human error, and ensures high consistency between batches.

· Precision Adjustable Cutting System: The integrated adjustable blade mechanism delivers uniform slices or cubes. Whether requiring paper-thin cheese slices or neat cubes, the Wanli Fully Automatic Ultrasonic Cheese Slicer achieves it effortlessly through precise parameter control. It minimizes product weight variation, directly enhancing raw material utilization and cost-control accuracy.

· Operational Efficiency Built for Productivity: With stable automated operation, the equipment performs 20 to 40 precise cutting cycles per minute, sustaining high-efficiency operation. This not only liberates operators from repetitive, labor-intensive manual work—significantly reducing labor costs and dependence—but also reliably boosts overall production line capacity.

· Hygiene Philosophy Implemented Throughout: Core contact components are constructed from high-quality, food-grade stainless steel with smooth, crevice-free surfaces. The modular design allows key parts like the blade head and conveyor belt to be quickly disassembled and reassembled, facilitating thorough and rapid cleaning and maintenance. This ensures the equipment maintains optimal hygienic condition, meeting requirements of certification systems like HACCP.

Core Value Infusing Dairy and Baking Enterprises with Powerful Momentum

Choosing the Wanli Fully Automatic Ultrasonic Cheese Slicer means opting for a more competitive mode of production. Wanli Machinery provides not just a machine, but a complete solution for enhancing quality, efficiency, and profitability.

· Superior Product Quality: Ensures every slice of cheese or soft pastry boasts perfect appearance and precise specifications, strengthening premium brand image and customer satisfaction.

· Significant Economic Benefits: Achieves rapid return on investment by reducing product waste, saving labor costs, and increasing production line throughput.

· Seamless Production Integration: With its compact design, it functions as a standalone workstation or integrates flexibly into existing packaging or sorting lines, elevating overall automation levels.

Frequently Asked Questions

1. What products is this machine primarily suitable for?

The Wanli Fully Automatic Ultrasonic Cheese Slicer is optimized for processing soft, sticky products. It is ideal for various fresh cheeses, cream cheese, mozzarella, soft breads, cream cakes, and pastries with similar textures. Its pressure-free cutting perfectly preserves the texture of these products.

2. Can ultrasonic cutting truly completely solve cheese sticking to the blade?

Yes. This is a core advantage of Wanlisonic ultrasonic technology. The high-frequency vibrating blade creates microscopic separation from the product during cutting, greatly reducing contact area and friction. This virtually eliminates product adhesion to the blade, ensuring cutting continuity and clean slice surfaces.

3. Are the operation and maintenance of the equipment highly demanding for technicians?

We are committed to lowering the technical barrier. The equipment features a full touchscreen control with an intuitive interface; ordinary operators can become proficient after training. Daily cleaning and maintenance are very straightforward thanks to stainless steel materials and modular design. Wanli Group also provides detailed operation manuals and professional remote support.

4. What is the adjustment range for cutting thickness and speed? Can it meet our variable production needs?

Absolutely. The Wanli Fully Automatic Ultrasonic Cheese Slicer allows precise adjustment of cutting thickness and operational speed (20-40 cycles per minute) within a wide range. Combined with the storable recipe function, you can quickly switch between different product specifications, making it perfectly suited for modern facilities requiring small-batch, multi-variety production.

5. How is long-term stability and hygiene guaranteed in different production environments?

Zhangzhou Wanli selects durable, corrosion-resistant food-grade stainless steel as the primary material. The robust construction ensures stability during long-term operation. Hygienic design is integral throughout, with smooth surfaces and detachable parts facilitating deep cleaning. Furthermore, the equipment operates smoothly with low noise, adapting well to various production environments.

Wanli Machinery, empowering the food industry with innovative technology. We look forward to the Wanli Fully Automatic Ultrasonic Cheese Slicer becoming your reliable partner in enhancing quality, efficiency, and competitiveness.

Hot News

Hot News2025-12-14

2025-12-13

2025-12-12

2025-12-11

2025-12-10

2025-12-08