Contact Info

Unit 1011, Pingning Industrial, Longhai District, Zhangzhou City, Fujian Province

New York.

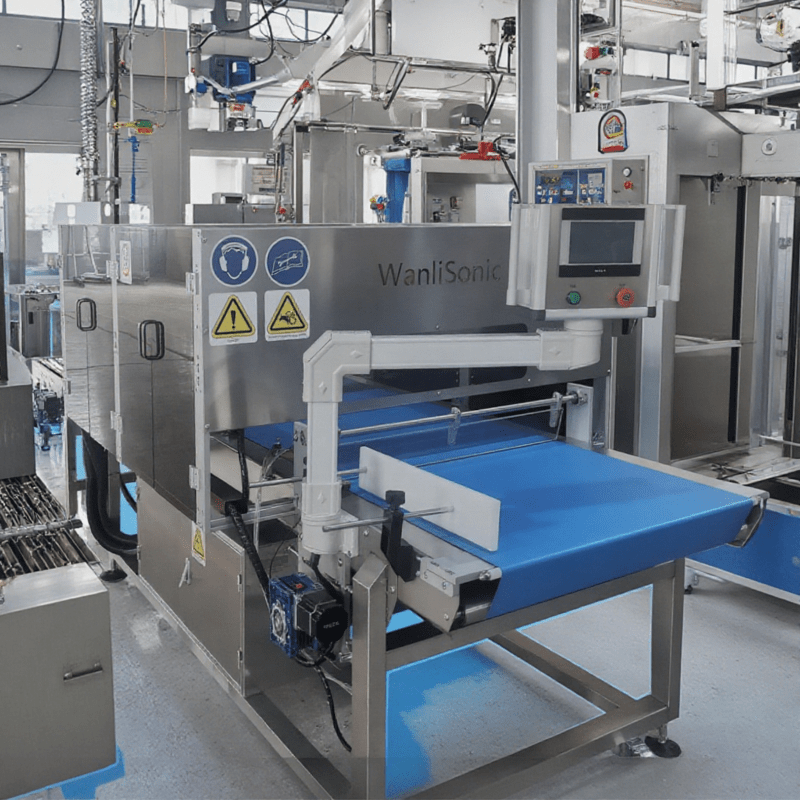

In the food processing industry, sheet cakes are highly popular for their rich flavors and diverse forms. However, for producers, efficiently, precisely, and hygienically cutting sheet cakes remains a significant challenge. Zhangzhou Wanli, with its innovative ultrasonic food cutting equipment, brings a revolutionary solution to sheet cake cutting.

Precision Positioning Initiates an Efficient Cutting Journey

The video begins by showcasing the automatic tracking ultrasonic cutting equipment's precise positioning capability for 400mm*600mm sheet cakes. As the cake slowly enters the cutting area, the system acts as if it possesses "intelligent eyes," capable of real-time monitoring of the cake's position and movement speed to ensure it remains correctly positioned for cutting. This feature is crucial, as the cake's position might shift slightly during conveying in actual production. Leveraging advanced automatic tracking technology, this Wanli equipment can swiftly adjust the cutting path regardless of the cake's entry orientation, guaranteeing cutting precision.

Furthermore, the equipment demonstrates robust continuous operation capability. Even with cakes entering the cutting area consecutively, it performs cutting tasks methodically, significantly boosting production efficiency and meeting the demands of large-scale production. This is undoubtedly a major advantage for food processing enterprises pursuing high output.

Vertical and Horizontal Cuts Demonstrate Masterful Cutting Craftsmanship

During the cutting process, the vertical cutting blade exhibits exceptional performance. It employs ultrasonic cutting technology, utilizing energy generated from high-frequency vibrations to effortlessly penetrate the cake, achieving clean and neat cuts. The cut cake strips remain connected post-cut; this design ensures cutting integrity while facilitating subsequent handling and packaging. Simultaneously, the equipped detection photoelectric system functions like a meticulous "supervisor," accurately sensing the cake's edges to ensure every cut is made in the correct position, preventing uneven cutting.

Based on preset dimensions, the equipment automatically adjusts cutting parameters. In the video, the current vertical cutting size is set to 25 millimeters. Such precise control ensures consistent thickness for every cake slice, delivering a uniform taste experience for consumers.

The horizontal cutting phase is equally impressive. The equipment is fitted with detection sensors that enable automatic counting and allow flexible adjustment of trimming dimensions according to production needs. The current horizontal cutting size is 40 millimeters. The resulting cake pieces are neatly arranged, uniform in size, and highly visually appealing. This combination of vertical and horizontal cutting fully utilizes the equipment's versatility, catering to diverse customer requirements for cake shapes and sizes.

Intelligent Design Ensures Effortless Operation and Maintenance

This Wanli automatic tracking ultrasonic cutting equipment exemplifies a strong focus on intelligent design. Operators can easily manage the entire cutting process through simple settings. This user-friendly design significantly reduces operational difficulty, enabling rapid proficiency even for personnel without specialized technical backgrounds, thereby saving substantial training costs and time for enterprises.

The equipment also excels in maintenance. Its modular design allows key components to be independently disassembled and replaced. If a component fails, maintenance personnel can quickly identify the issue and perform repairs without requiring extensive disassembly of the entire system. This not only improves maintenance efficiency but also reduces equipment downtime, ensuring production continuity.

Finished Product Showcase Highlights Exceptional Cutting Quality

The video concludes by displaying the finished cut products. The neatly arranged cake pieces feature smooth, flat cut surfaces completely free of crumbs or frayed edges. When separated, the internal structure remains intact, and the soft texture is almost palpable through the screen. Pre-set trimming waste is automatically ejected after a designated time, further ensuring product neatness and hygiene. This high-quality cutting result undoubtedly enhances product market competitiveness, helping food processing enterprises win greater consumer favor.

Frequently Asked Questions (FAQ)

Q: Can this equipment cut other foods besides sheet cakes?

A: Yes, our automatic tracking ultrasonic cutting equipment offers strong versatility. With appropriate adjustments and configuration, it can also be used for cutting other foods of similar texture and dimensions, such as certain soft pastries and breads.

Q: Will the cutting accuracy degrade over time with use?

A: No. We use high-quality materials and advanced manufacturing processes, ensuring stable equipment performance. Furthermore, regular maintenance helps keep the equipment operating at optimal cutting precision.

Q: What is your service response time if the equipment encounters a malfunction?

A: We have established a comprehensive after-sales service system. For international markets, we will dispatch technical personnel for repairs as quickly as possible based on the client's location and specific circumstances, ensuring prompt restoration of normal equipment operation.

Zhangzhou Wanli, with its innovative ultrasonic food cutting equipment, provides a completely new solution for sheet cake cutting. Choosing Wanli means choosing an efficient, precise, and intelligent food processing experience. Visit our official website at wanlimachinery.com to learn more. Let us collaborate to create a brighter future for the food processing industry!

Hot News

Hot News2025-12-14

2025-12-13

2025-12-12

2025-12-11

2025-12-10

2025-12-08