Contact Info

Unit 1011, Pingning Industrial, Longhai District, Zhangzhou City, Fujian Province

New York.

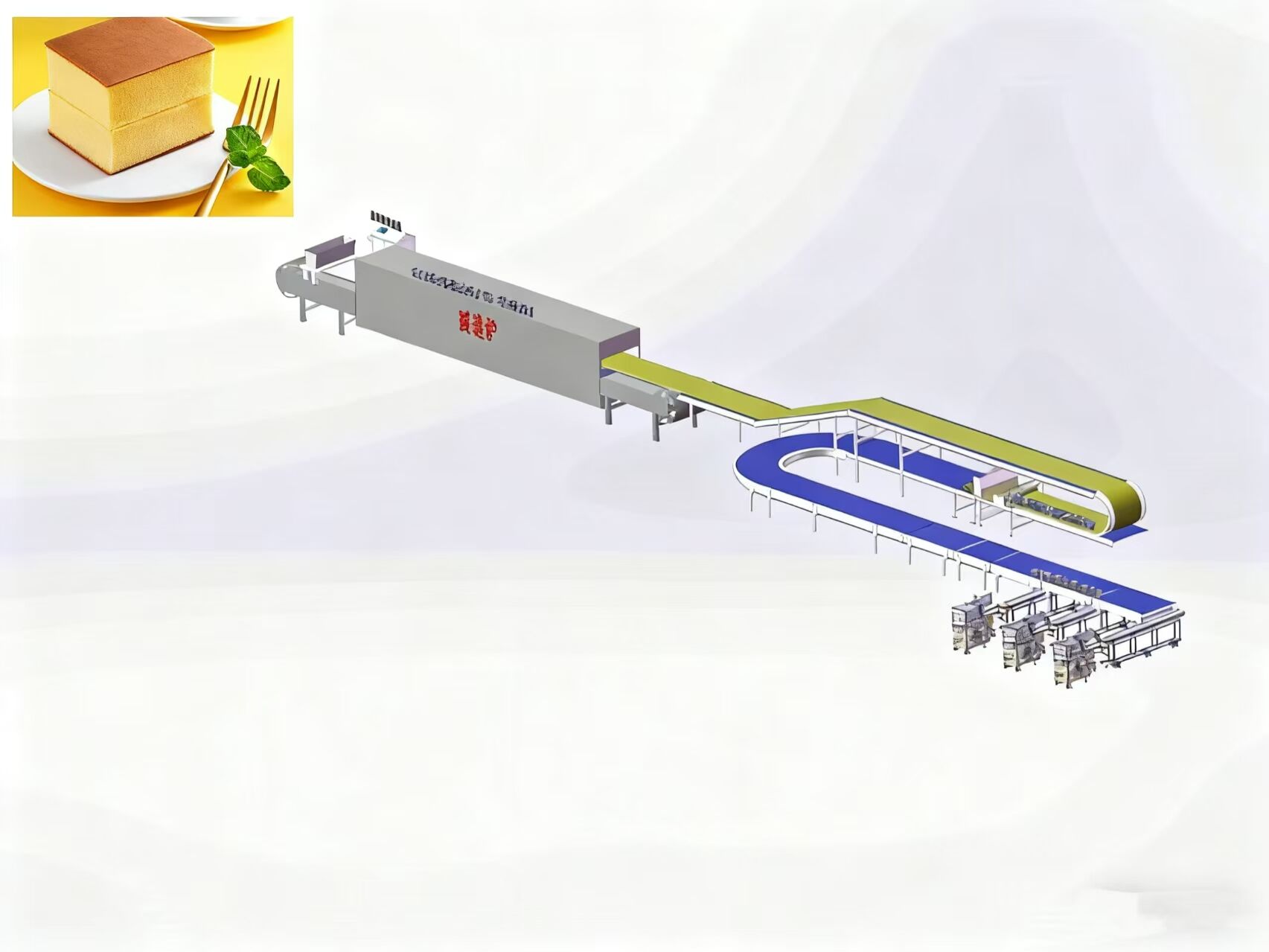

In the modern baking industry, the level of production automation and product standardization directly impacts enterprises' market competitiveness. Through innovative ultrasonic technology and automated processes, Zhangzhou Wanli introduces the Wanli Fully Automated Cake Production Line, providing global baking enterprises with complete solutions from raw material processing to finished product packaging.

Innovative Technical Advantages

The Wanli Fully Automated Cake Production Line adopts modular design, integrating seven core systems: raw material processing, batter preparation, precision baking, rapid cooling, intelligent decoration, automated packaging, and central control. The line's most significant technological breakthrough lies in perfect integration of ultrasonic cutting technology with automated production processes, achieving non-contact cutting through high-frequency vibrations that ensures smooth, aesthetically pleasing product surfaces while maintaining cake structure integrity.

Compared to traditional equipment, this production line offers distinct advantages:

· Precision Control: The batter dispensing system ensures accurate tray placement with weight error controlled within 3%

· Flexible Production: Product specifications can be modified by adjusting ultrasonic cutting speed without requiring molds

· Hygiene and Safety: Fully enclosed design combined with food-grade stainless steel materials minimizes contamination risks

· Energy Efficiency: Intelligent temperature control systems and energy-saving designs reduce energy consumption by 30% compared to conventional equipment

Intelligent Production System

The Wanli Fully Automated Cake Production Line demonstrates intelligence across multiple levels:

Smart Control System

Utilizes industrial-grade PLC and servo motor coordination, featuring color touchscreen interfaces supporting storage and rapid recall of 20 product recipes. Operators can easily master equipment operation through intuitive graphical interfaces, achieving precise adjustment of production parameters.

Adaptive Production Units

Each production stage incorporates smart sensing devices that automatically adjust process parameters based on material characteristics. From batter viscosity monitoring to baking temperature control, the system continuously optimizes production conditions to ensure consistent product quality.

Data Management Platform

Integrated cloud data storage and analysis functions enable real-time equipment status monitoring and production report generation. Through remote diagnostic systems, technical personnel can promptly address equipment anomalies, minimizing downtime.

Outstanding Performance

The Wanli Fully Automated Cake Production Line delivers significant benefits:

High Production Capacity

Single-line output increases over 50%compared to traditional methods, perfectly adapting to different scale production requirements.

Quality Assurance

Product consistency reaches 99%, substantially enhancing brand standardization levels.

Cost Optimization

Automated production reduces labor requirements by 60%while minimizing material waste.

Professional Service System

Wanli Group has established a comprehensive global service network, providing clients with all-around support:

Customized Solutions

Offers personalized production line configurations based on client site conditions and capacity requirements.

Professional Training

Technical teams provide comprehensive training from equipment operation to maintenance.

Continuous Support

Implements rapid response mechanisms to ensure trouble-free client production.

FAQ

1. Does the production line support different types of cakes?

The Wanli Fully Automated Cake Production Line utilizes modular design, adapting to various cake types including sponge cakes and chiffon cakes through parameter adjustments, offering excellent production flexibility.

2. How long does equipment specification changeover require?

Through intelligent recipe management systems, specification changes complete within 3 minutes. The equipment supports 20 sets of process parameter storage, ensuring production continuity.

3. Is routine maintenance complicated?

The equipment features modular design with smart maintenance reminder systems. Routine cleaning and maintenance tasks are straightforward, significantly reducing maintenance costs.

4. What are the site requirements for the production line?

We provide professional site planning services. Technical personnel offer optimal layout solutions based on actual client conditions, ensuring efficient production line operation.

5. Are special process requirements supported?

Yes, personalized customization services are available, allowing equipment configuration and process adjustments according to specific client needs.

The Wanli Fully Automated Cake Production Line offers innovative production models for the baking industry through its advanced technology and exceptional performance. We look forward to collaborating with global clients to jointly advance intelligent upgrading in the baking industry.

Hot News

Hot News2025-12-14

2025-12-13

2025-12-12

2025-12-11

2025-12-10

2025-12-08