Kontaktoplysninger

Enhed 1011, Pingning Industrial, Longhai-distrikt, Zhangzhou-by, Fujian-provinsen

New York.

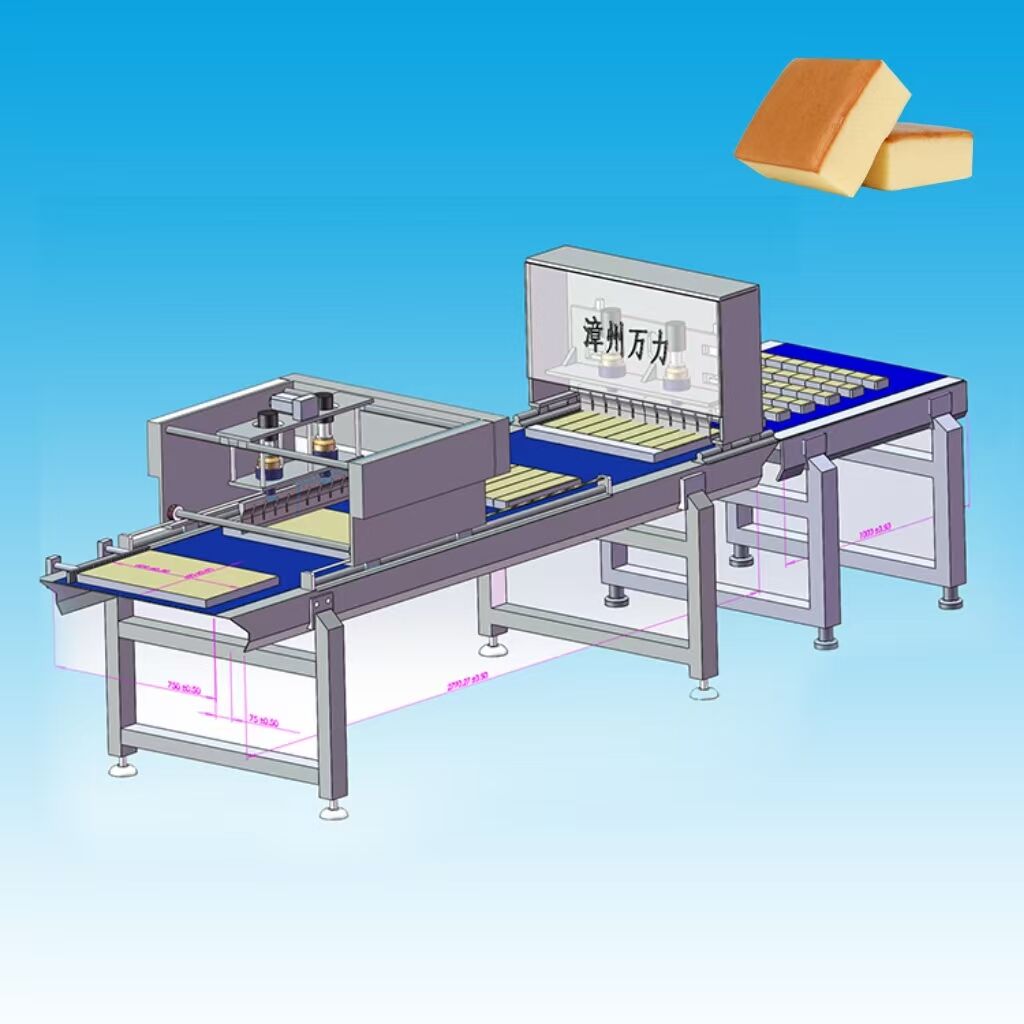

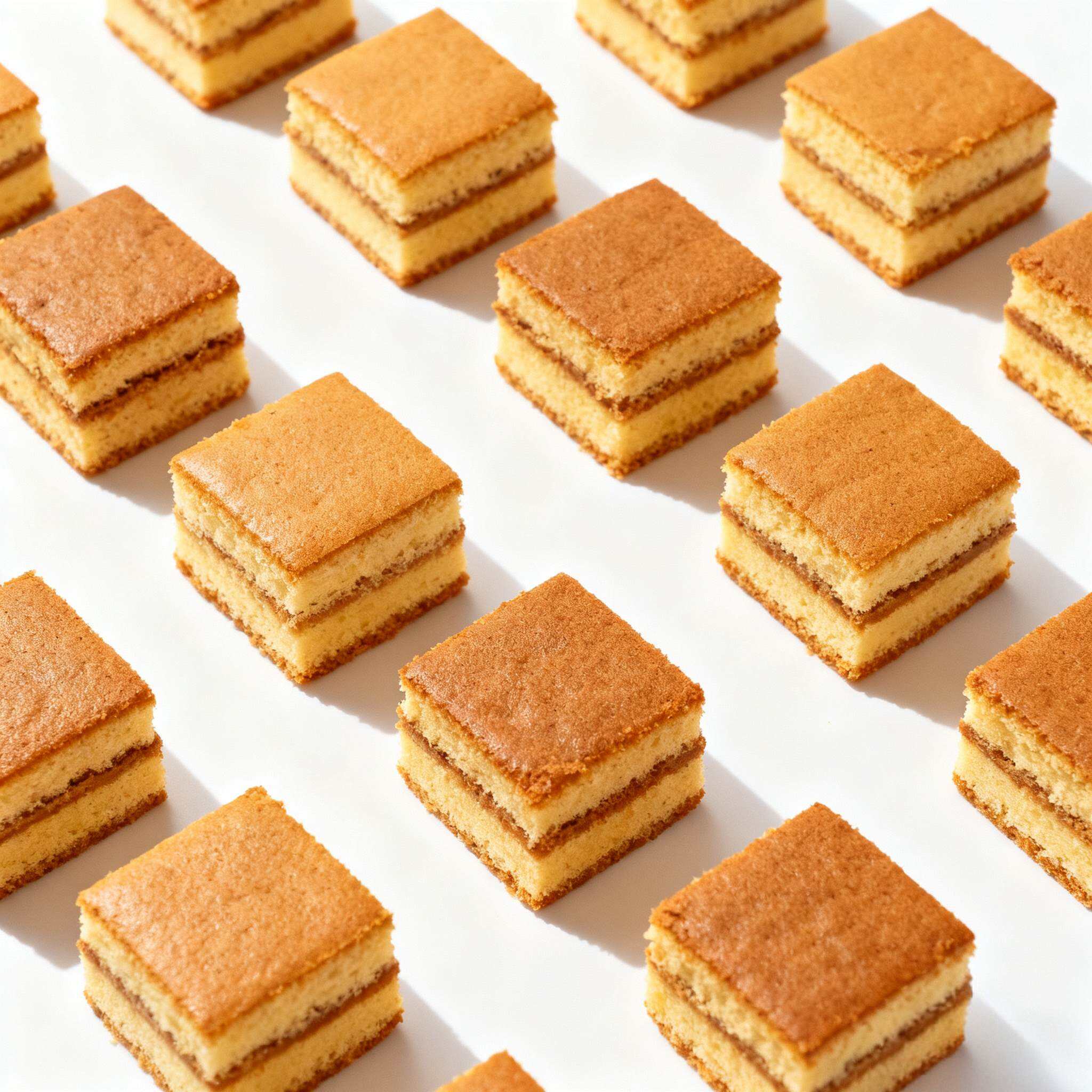

I bagvareindustrien har det i lang tid været en udfordring at opnå præcise skæringer af produkter som rektangulære kager og cheesecakes. Traditionelle knivskæringsmetoder fører ofte til produktdeformation, klistrende blade og ru overflade, hvilket kompromitterer udseendet og medfører spild af materiale. Ved brug af nyeste ultralyd teknologi, Zhangzhou Wanli introducerer den revolutionerende Wanli helt automatiske ultralyd kageskærer , designet til at give bageriernes verden over den perfekte løsning til skæring af rektangulære og mange andre typer kager.

Princip og fordele ved ultralydsskæringsteknologi

Ultralydskæring er en innovativ berøringsfri bearbejdningsteknologi. Kerneprincippet består i, at en ultralydsgenerator omdanner elektrisk energi til højfrekvente mekaniske vibrationer ved 20.000 cyklusser per sekund (20 kHz). Disse højfrekvente vibrationer overføres gennem en transducer til et specielt designet skæreblad, hvilket fremkalder mikroskopiske vibrationer, som er usynlige for det menneskelige øre.

Når dette "vibrerende blad" kommer i kontakt med fødevarer som kage, anvender det ikke traditionelt mekanisk tryk til "knusende skæring". I stedet bruger det højfrekvent vibrerende energi til øjeblikkeligt og forsigtigt at adskille de molekylære bindinger i fødevarematerialet. Denne proces giver banebrydende fordele:

Kerneinnovationer i Wanli fuldautomatiske ultralydskage-skærer

Bygger på denne kermeteknologi, Wanli Gruppen gaver den Wanli fuldautomatiske ultralydskage-skærer , designet specifikt til moderne produktionslinjer. Det er ikke blot et skæreværktøj, men et komplet intelligent og højt tilpasningsdygtigt produktionssystem.

1. Alsidsig og højt tilpasningsdygtig skæring

Konstruktionen af dette Wanli helt automatiske ultralydskæreapparat til kager tager fuldt ud højde for produktionsfleksibilitet. Det håndterer effektivt standard rektangulære kager og kan ved hjælp af enkelte programindstillinger og tilbehørsjusteringer nemt skifte til skæring i skiver, stave og endda samtidigt og præcist skære to runde produkter (f.eks. mousse i ringform). Denne "flerfunktionsmaskin"-egenskab gør den til det ideelle valg for at håndtere varierede produktlinjer og opnå mindre serier med høj fleksibilitet.

2. Intelligent og brugervenlig design

Intelligens er en integreret del af Wanli-udstyr. Denne maskine er udstyret med en intuitiv farve-touchskærm med et klart og enkelt betjeningsinterface. Alle parametre, herunder skæretykkelse, hastighed og tilstand, kan indstilles og gemmes med et enkelt tryk. Det avancerede styresystem sikrer, at hver eneste skæring er perfekt nøjagtig, reducerer menneskelige fejl til næsten nul og forbedrer produktets ensartethed markant.

Vedligeholdelsen er lige så enkel. Udstyret er modulformet, så det er nemt at demontere og samle vigtige komponenter. Det er især bemærkelsesværdigt, at det innovative automatiske rengøringssystem kan rengøre og tørre den ultralydsskarpede klinge - Hvad? Dette reducerer drastisk nedetid for manuel rengøring og sikrer produktionen hygiejne og kontinuitet.

3. Det er ikke muligt. Udestående kapacitet og økonomiske fordele

Med en stabil skæringshastighed på 30-40 cyklusser i minuttet den Wanli fuldautomatiske ultralydskage-skærer kan fungere uophørligt døgnet rundt. Den erstatter direkte flere kvalificerede arbejdere, hvilket ikke blot betydeligt sparer høje arbejdskraftomkostninger, men også eliminerer kvalitetsudsving forårsaget af arbejdernes træthed. Samtidig medfører et næsten nultab af materialeadhäsion direkte betydelige omkostningsbesparelser. Investering i Wanli-udstyr betyder samtidig forbedringer af kvalitet, effektivitet og rentabilitet.

Konklusion

I et stadig mere konkurrencepræget globalt fødevaremarked er stræben efter effektivitet, kvalitet og fleksibilitet uendelig. Wanli Group's fuldt automatiske ultralydskære til kage er præcis det værktøj, der er skabt til dette formål. Det omdefinerer skærestandarder med teknologi og hjælper bagervirksomheder med at bryde igennem produktionsflaskehalse og skabe mere konkurrencedygtige produkter.

Vi byder globale partnere velkommen til at kontakte os og sammen udforske de muligheder, som ultralydskæringsteknologi kan bringe til jeres virksomhed.

Ofte stillede spørgsmål (FAQ)

Spørgsmål 1: Kan denne maskine virkelig løse problemet med, at flødeskumkager sidder fast på kniven?

Svar 1: Absolut. Dette er en kerdefordel ved ultralydskæring . De 20 kHz højfrekvente vibrationer skaber et mikroskopisk vibrationsmellemrum mellem kniven og fødevarematerialet, hvilket grundlæggende eliminerer klæbrighedskræfterne. Det er særlig effektivt til behandling af stærkt klæbrige materialer som flødeskum, påstrøg og ost.

Spørgsmål 2: Er det operationelt kompliceret at skifte fra at skære én varetype til en anden (f.eks. fra rektangulær til cirkulær)?

A2: Det er meget enkelt. For standardkontakter skal du kun hente de forudindstillede procesprogrammer op på berøringsskærmen. Hvis der skal skiftes fixturer eller blade, gør vores modulære design også denne proces hurtig og nem, hvilket minimerer omstillingstiden.

Q3: Er hygiejnisk rengøring af maskinen besværlig?

A3: Takket være det automatiske rengøringsystem og konstruktionen i rustfrit stål til fødevarebrug er daglig rengøring og vedligeholdelse meget praktisk. Det automatiske program kan rengøre kniven med mellemrum efter tidsplan, og hovedkonstruktionen har ingen hygiejniske døde punkter, hvilket overholder strenge internationale krav til fødevaresikkerhedssystemer som HACCP.

Q4: Kræver vedligeholdelse af udstyret specialiseret teknisk personale?

A4: Nej. Udstyret er designet med fokus på nem vedligeholdelse. Almindelig rengøring, smøring og udskiftning af sliddele er tydeligt beskrevet i vores betjeningsvejledning. Desuden Wanli Gruppen yder omfattende fjernbetjeningsteknisk support og et lokaliseret service netværk.

Q5: Hvordan kan jeg sikre, at udstyret opfylder mine specifikke produktionsbehov?

A5: Wanli Machinery tilbyder professionel rådgivning før salg. Vores ingeniører kan anbefale den mest velegnede modelkonfiguration baseret på dine produkters egenskaber, størrelseskrav og kapacitetsmål. Vi kan endda levere skræddersyede løsninger for at sikre, at udstyret integreres perfekt i din produktionslinje.

Seneste nyt

Seneste nyt2025-12-14

2025-12-13

2025-12-12

2025-12-11

2025-12-10

2025-12-08