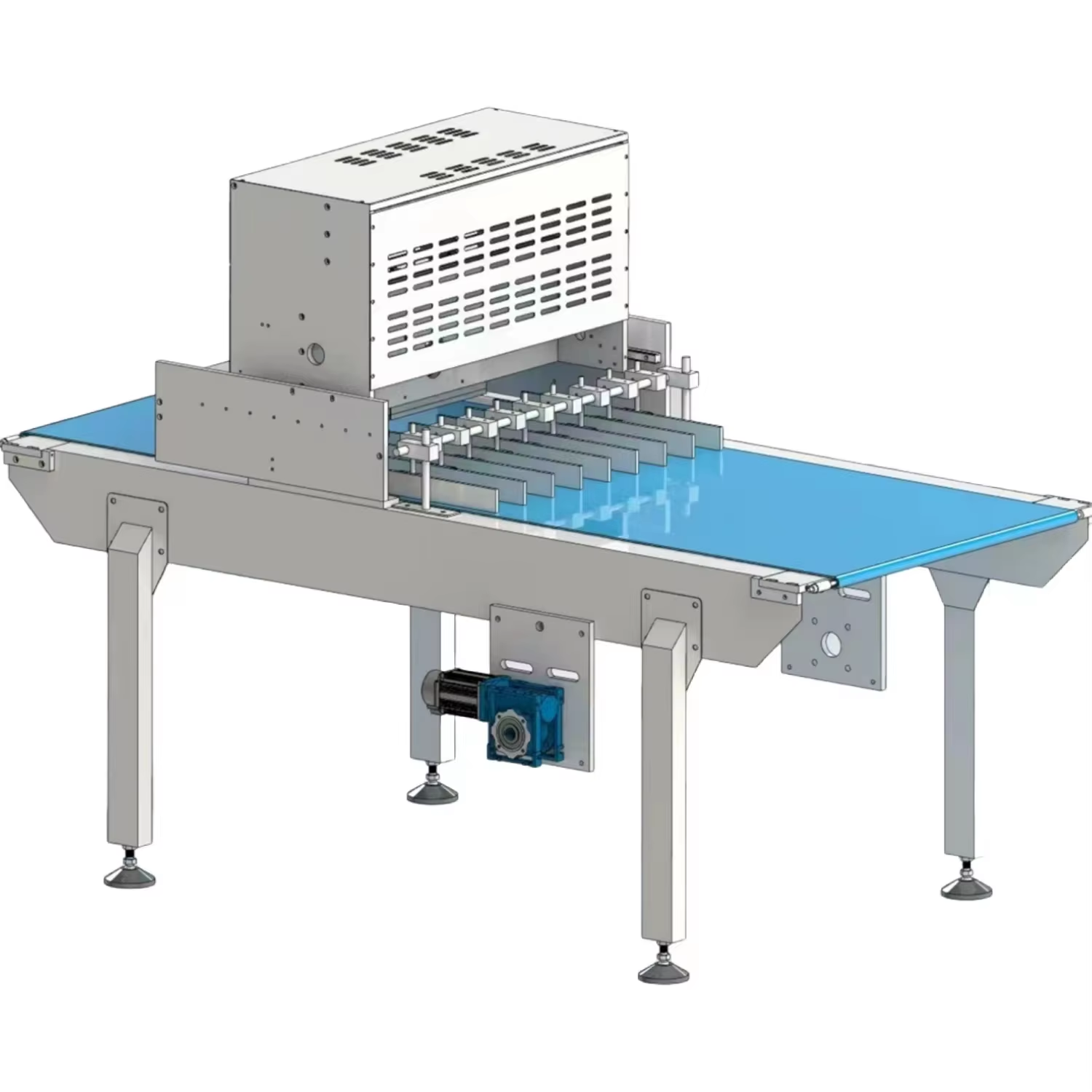

The confectionery industry faces unique challenges when processing sticky, dense candy products like nougat, where traditional cutting methods often result in product deformation, blade sticking, and inconsistent portion sizes. Modern food processing facilities are increasingly turning to advanced ultrasonic technology to overcome these obstacles and achieve the precision required for commercial-scale candy production. An ultrasonic nougat cutting machine represents a revolutionary approach to handling challenging confectionery materials that have historically been difficult to process efficiently.

The integration of ultrasonic technology in candy processing equipment has transformed how manufacturers approach the cutting and portioning of sticky confectionery products. This sophisticated machinery utilizes high-frequency vibrations to create clean, precise cuts without the common issues associated with conventional blade cutting methods. The technology delivers consistent results across various nougat formulations, from soft honey-based varieties to harder nut-embedded compositions.

Understanding Ultrasonic Cutting Technology in Confectionery Applications

Fundamental Principles of Ultrasonic Food Processing

Ultrasonic cutting technology operates on the principle of high-frequency mechanical vibrations, typically ranging from 20 to 40 kilohertz, which are transmitted through a specially designed cutting blade or horn. These vibrations create microscopic oscillations that effectively reduce friction between the cutting tool and the food product, allowing for smooth penetration through even the stickiest materials. The ultrasonic waves generate localized heating at the cutting interface, which temporarily softens the product material just enough to facilitate clean separation without affecting the overall product structure.

The amplitude and frequency of the ultrasonic vibrations can be precisely controlled to match the specific characteristics of different nougat formulations. This adaptability ensures optimal cutting performance across a wide range of product densities, temperatures, and ingredient compositions. The technology maintains consistent cutting quality regardless of ambient conditions, making it particularly valuable in commercial production environments where temperature and humidity variations are common.

Advantages Over Traditional Mechanical Cutting Methods

Traditional guillotine or rotary cutting systems struggle with nougat due to its adhesive properties and variable texture composition. Conventional blades often become clogged with product residue, requiring frequent cleaning and resulting in production downtime. The sticky nature of nougat causes significant product waste as material adheres to cutting surfaces and must be scraped away, leading to inconsistent portion weights and reduced yield efficiency.

Ultrasonic cutting eliminates these challenges by preventing product adhesion to the cutting blade through continuous vibration. The self-cleaning action of the ultrasonic blade means minimal product buildup and significantly reduced maintenance requirements. This results in higher production efficiency, improved product quality consistency, and reduced material waste, making the ultrasonic nougat cutting machine an economically advantageous solution for commercial confectionery operations.

Technical Specifications and Operating Parameters

Power Systems and Frequency Control

Modern ultrasonic nougat cutting systems typically feature variable power control ranging from 500 to 2000 watts, allowing operators to adjust the cutting intensity based on specific product requirements. The frequency generators maintain precise control over ultrasonic wave production, ensuring consistent cutting performance throughout extended production runs. Advanced systems incorporate digital feedback controls that automatically adjust power levels based on product resistance and cutting speed requirements.

The ultrasonic generator components are designed for continuous industrial operation, featuring robust construction and thermal management systems to prevent overheating during extended use. Many systems include programmable memory functions that store optimal settings for different nougat formulations, enabling quick changeovers between product varieties without manual recalibration. This automation capability significantly reduces setup time and minimizes the potential for operator error in parameter selection.

Cutting Blade Design and Materials

The cutting blades used in ultrasonic nougat processing are manufactured from specialized titanium alloys or hardened stainless steel designed to efficiently transmit ultrasonic vibrations while maintaining sharp cutting edges. The blade geometry is carefully engineered to optimize ultrasonic wave transmission and minimize energy loss during the cutting process. Surface treatments and coatings further enhance the non-stick properties of the blade, reducing product adhesion and extending blade life.

Blade thickness and profile configurations can be customized to accommodate different nougat cutting requirements, from thin slicing applications to thicker portioning cuts. The modular design of many ultrasonic cutting systems allows for quick blade changes without requiring specialized tools or extensive downtime. Regular blade maintenance involves simple inspection and occasional replacement, with typical blade life extending several months under normal production conditions.

Production Benefits and Quality Improvements

Precision Cutting and Portion Control

One of the most significant advantages of ultrasonic nougat cutting technology is the exceptional precision achievable in portion control and product uniformity. The consistent cutting action eliminates the variations commonly seen with mechanical cutting methods, resulting in uniform piece weights and dimensions that meet strict commercial specifications. This precision is particularly important for packaged candy products where weight accuracy directly impacts profitability and regulatory compliance.

The clean cutting action preserves the visual appeal of nougat products by maintaining sharp, defined edges without the crushing or deformation typical of traditional cutting methods. This enhanced appearance quality is crucial for premium confectionery products where visual presentation significantly influences consumer purchasing decisions. The ability to achieve consistent, professional-looking cuts across all products in a production run helps maintain brand reputation and customer satisfaction.

Increased Production Efficiency and Reduced Waste

Ultrasonic cutting technology significantly increases overall production throughput by eliminating the frequent cleaning and maintenance breaks required with conventional cutting systems. The continuous operation capability allows for uninterrupted production runs, maximizing equipment utilization and reducing labor costs associated with machine maintenance. The reduced downtime translates directly into increased daily production capacity and improved return on investment for processing equipment.

Material waste reduction is another crucial benefit, as the clean cutting action minimizes product loss due to adhesion and deformation. The precise cutting capability also reduces the need for trimming or reworking of improperly cut pieces, further improving yield efficiency. In high-volume production environments, these waste reductions can result in significant cost savings and improved profit margins, making the ultrasonic nougat cutting machine a valuable investment for commercial confectionery operations.

Applications Across Different Nougat Varieties

Soft and Chewy Nougat Processing

Soft nougat varieties, characterized by their high moisture content and flexible texture, present unique challenges for conventional cutting methods due to their tendency to compress and stick to cutting surfaces. Ultrasonic technology excels in processing these products by maintaining consistent cutting pressure while preventing the compression that leads to uneven cuts and product deformation. The gentle cutting action preserves the delicate structure of soft nougat while achieving clean separation between pieces.

The temperature control capabilities of ultrasonic systems are particularly beneficial for soft nougat processing, as the controlled heating at the cutting interface helps maintain optimal product consistency without affecting the overall product temperature. This localized heating effect also helps seal the cut edges, reducing moisture loss and extending product shelf life. The ability to process soft nougat at various temperatures expands production flexibility and accommodates different manufacturing schedules.

Hard and Nut-Embedded Nougat Varieties

Hard nougat formulations containing nuts, dried fruits, or other inclusions require different cutting approaches due to their heterogeneous composition and varying density throughout the product. Ultrasonic cutting technology adapts automatically to these density variations, maintaining consistent cutting quality regardless of the presence of hard inclusions. The high-frequency vibrations effectively cut through both the nougat matrix and embedded ingredients without causing cracking or separation.

The power and frequency adjustability of ultrasonic systems allows operators to optimize cutting parameters for specific inclusion types and concentrations. This adaptability ensures that products with different nut varieties or inclusion levels can all be processed efficiently using the same equipment, reducing the need for multiple specialized cutting systems. The consistent results across different product formulations help maintain quality standards and reduce production complexity in facilities processing multiple nougat varieties.

Maintenance Requirements and Operational Considerations

Routine Maintenance Procedures

Regular maintenance of ultrasonic nougat cutting equipment involves several key procedures designed to ensure optimal performance and extend equipment life. Daily cleaning protocols include thorough sanitization of all food-contact surfaces using approved cleaning agents that are compatible with ultrasonic components. The blade assembly requires regular inspection for wear patterns and edge sharpness, with replacement schedules typically based on production volume and product characteristics.

Ultrasonic generator maintenance involves periodic calibration checks to ensure frequency and power output remain within specified parameters. Most modern systems include diagnostic capabilities that monitor performance metrics and alert operators to potential issues before they affect production quality. The modular design of many ultrasonic systems facilitates quick component replacement and minimizes maintenance downtime, allowing for efficient servicing during scheduled production breaks.

Training and Safety Requirements

Proper operator training is essential for safe and effective operation of ultrasonic nougat cutting equipment. Training programs typically cover equipment operation, safety procedures, basic troubleshooting, and maintenance protocols. Operators must understand the relationship between cutting parameters and product characteristics to make appropriate adjustments for different nougat formulations and production requirements.

Safety considerations include proper personal protective equipment, understanding of ultrasonic wave exposure limits, and emergency shutdown procedures. The high-frequency vibrations generated by ultrasonic equipment require specific handling precautions to prevent operator exposure to potentially harmful vibration levels. Regular safety training updates ensure that all personnel remain current with best practices and regulatory requirements for ultrasonic food processing equipment operation.

Cost Analysis and Return on Investment

Initial Investment Considerations

The initial capital investment for an ultrasonic nougat cutting machine typically ranges from moderate to high depending on production capacity requirements and automation level. However, this investment must be evaluated against the total cost of ownership, including reduced maintenance expenses, decreased material waste, and improved production efficiency. Many manufacturers find that the operational savings achieved through ultrasonic technology justify the initial equipment cost within the first year of operation.

Financing options and leasing programs are often available for ultrasonic cutting equipment, allowing manufacturers to spread the investment cost over several years while immediately benefiting from improved production capabilities. The modular nature of many systems also allows for phased implementation, starting with core functionality and adding advanced features as production requirements grow or additional capital becomes available.

Long-term Operational Savings

Long-term operational savings from ultrasonic nougat cutting technology come from multiple sources, including reduced labor costs due to decreased maintenance requirements, lower material waste percentages, and improved production throughput. The consistent cutting quality reduces the need for manual sorting and rework, further reducing labor costs and improving overall production efficiency. Energy consumption is typically lower than conventional cutting systems due to the efficient power transfer characteristics of ultrasonic technology.

The extended equipment life typical of well-maintained ultrasonic systems contributes to favorable long-term economics, as replacement intervals are generally longer than traditional mechanical cutting equipment. The ability to process a wide variety of products using the same equipment also provides operational flexibility that can accommodate changing market demands without requiring additional capital investment in specialized cutting equipment.

FAQ

What types of nougat products can be processed with ultrasonic cutting technology?

Ultrasonic cutting technology is versatile enough to handle virtually all nougat varieties, from soft honey-based formulations to hard, nut-embedded products. The adjustable power and frequency settings allow operators to optimize cutting parameters for different product characteristics, including varying densities, temperatures, and inclusion types. This adaptability makes ultrasonic systems suitable for facilities producing multiple nougat varieties using a single cutting system.

How does ultrasonic cutting affect product shelf life and quality?

Ultrasonic cutting actually helps preserve product quality and can extend shelf life by creating clean, sealed cut edges that reduce moisture loss and contamination risk. The gentle cutting action maintains product structure integrity while the minimal heating effect at the cutting interface helps seal cut surfaces. This preservation of product quality is particularly beneficial for premium confectionery products where appearance and texture are critical quality factors.

What are the typical maintenance requirements for ultrasonic nougat cutting equipment?

Maintenance requirements for ultrasonic cutting equipment are generally lower than traditional mechanical systems, involving daily cleaning, periodic blade inspection and replacement, and routine calibration checks of the ultrasonic generator. Most systems include diagnostic capabilities that monitor performance and alert operators to maintenance needs before they affect production quality. The modular design facilitates quick component replacement and minimizes maintenance downtime.

Can ultrasonic cutting systems be integrated into existing production lines?

Yes, ultrasonic nougat cutting systems are designed for integration into existing production lines with minimal modifications to surrounding equipment. Most systems feature standard conveyor interfaces and can be synchronized with upstream and downstream equipment for seamless operation. The compact footprint of many ultrasonic systems also allows for installation in space-constrained production environments without requiring extensive facility modifications.

Table of Contents

- Understanding Ultrasonic Cutting Technology in Confectionery Applications

- Technical Specifications and Operating Parameters

- Production Benefits and Quality Improvements

- Applications Across Different Nougat Varieties

- Maintenance Requirements and Operational Considerations

- Cost Analysis and Return on Investment

-

FAQ

- What types of nougat products can be processed with ultrasonic cutting technology?

- How does ultrasonic cutting affect product shelf life and quality?

- What are the typical maintenance requirements for ultrasonic nougat cutting equipment?

- Can ultrasonic cutting systems be integrated into existing production lines?