Contact Info

Unit 1011, Pingning Industrial, Longhai District, Zhangzhou City, Fujian Province

New York.

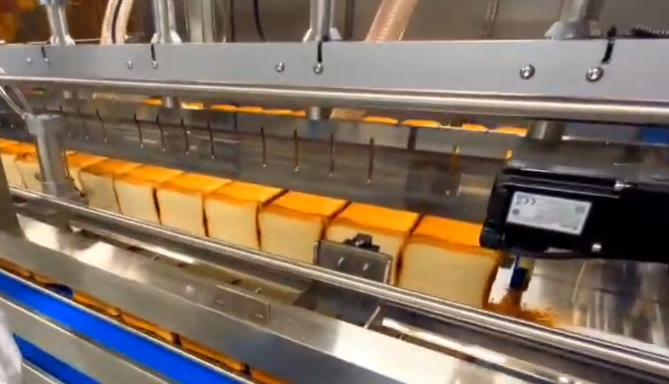

In the modern baking industry, production automation and process precision have become key factors for enterprises to enhance competitiveness. Zhangzhou Wanli has introduced the Wanli Fully Automatic Ultrasonic Toast Production Line, based on innovative ultrasonic cutting technology, providing comprehensive intelligent production solutions for global baking businesses.

Innovative Ultrasonic Cutting Technology

Traditional toast cutting methods often face challenges such as product deformation, excessive crumbs, and limited efficiency. The Wanli Fully Automatic Ultrasonic Toast Production Line utilizes unique high-frequency vibration technology, achieving precise cutting through 20,000 to 40,000 vibrations per second. This innovative non-contact cutting process perfectly preserves the soft texture of toast, ensuring each slice has uniform thickness and a smooth cutting surface.

Compared with traditional cutting methods, this technology demonstrates significant advantages:

· Pressure-Free Cutting: Avoids compression damage to soft toast structures.

· Smooth Cutting Surface: Clean and neat cutting surface, effectively reducing crumb generation.

· Precision Control: Cutting accuracy up to millimeter level, ensuring uniform product specifications.

· Hygiene and Safety: Fully enclosed design complies with international food safety standards.

Intelligent Control System

The Wanli Fully Automatic Ultrasonic Toast Production Line integrates multiple innovative technologies, showcasing outstanding performance characteristics.

Intelligent Control Platform

Utilizes advanced PLC and servo motor collaborative control, equipped with an intuitive touchscreen interface. The system supports three user login levels (Operator, Supervisor, Technician), enabling hierarchical production management and ensuring operational safety and professionalism.

Adaptive Adjustment System

Automatically optimizes cutting parameters based on toast texture characteristics. The unique temperature compensation technology ensures consistent cutting quality under various environmental conditions. Motor-driven rotating ultrasonic blades achieve high-speed precision cutting at 30 to 40 cycles per minute.

Remote Monitoring System

Integrated Ethernet remote access function allows for real-time equipment status monitoring. The intelligent diagnostic system provides early warnings for equipment abnormalities, ensuring maximum production continuity.

Outstanding Performance

The Wanli Fully Automatic Ultrasonic Toast Production Line delivers significant production benefits:

High Production Efficiency

Cutting speed of 30 to 40 cycles per minute substantially improves production efficiency.

Excellent Output Quality

Product integrity rate exceeds 99%, effectively reducing raw material waste.

Energy Saving and Environmental Protection

Energy consumption is reduced by 35%compared to traditional equipment, significantly optimizing operational costs.

Hygienic and Safe Design

Zhangzhou Wanli always prioritizes hygiene and safety in design:

· Full stainless steel structure and food-grade plastic materials, compliant with food safety standards.

· Equipped with ultraviolet sterilization function, ensuring production environment hygiene and safety.

· Safety protection grating design comprehensively ensures operator safety.

· Modular structure allows for easy cleaning and maintenance of core components.

Professional Technical Support

Wanli Group has established a comprehensive global service system:

· Provides personalized customized solutions.

· Professional technical team offers full guidance.

· 24-hour rapid response mechanism.

FAQ

1. What types of toast products is the equipment suitable for?

The Wanli Fully Automatic Ultrasonic Toast Production Line is suitable for various toast products, including white toast, whole wheat toast, and multigrain toast. The special ultrasonic cutting technology perfectly handles toast products containing ingredients such as nuts and dried fruits.

2. How long does it take to change production specifications?

With the intelligent memory system, specification changes can be completed within 2 minutes. The equipment supports storage of multiple process parameter sets, ensuring production flexibility.

3. What should be noted for daily cleaning and maintenance?

Routine cleaning checks are recommended per shift. The equipment provides intelligent maintenance reminders. The modular design allows quick disassembly of core components, with routine cleaning taking only 20 minutes.

4. What are the environmental requirements for the equipment?

It is suitable for standard food-grade production environments. Specific installation requirements can be confirmed through on-site guidance by professional technicians.

5. Does it support special cutting requirements?

It supports various custom needs. Wanli Group provides professional technical consultation and sampling services.

Wanli Machinery is always committed to providing innovative ultrasonic cutting solutions for global food enterprises. The Wanli Fully Automatic Ultrasonic Toast Production Line, with its excellent performance and intelligent design, sets a new technological benchmark for the baking industry. We look forward to collaborating with you to jointly promote innovative development in the baking industry.

Hot News

Hot News2025-12-14

2025-12-13

2025-12-12

2025-12-11

2025-12-10

2025-12-08