Contact Info

Unit 1011, Pingning Industrial, Longhai District, Zhangzhou City, Fujian Province

New York.

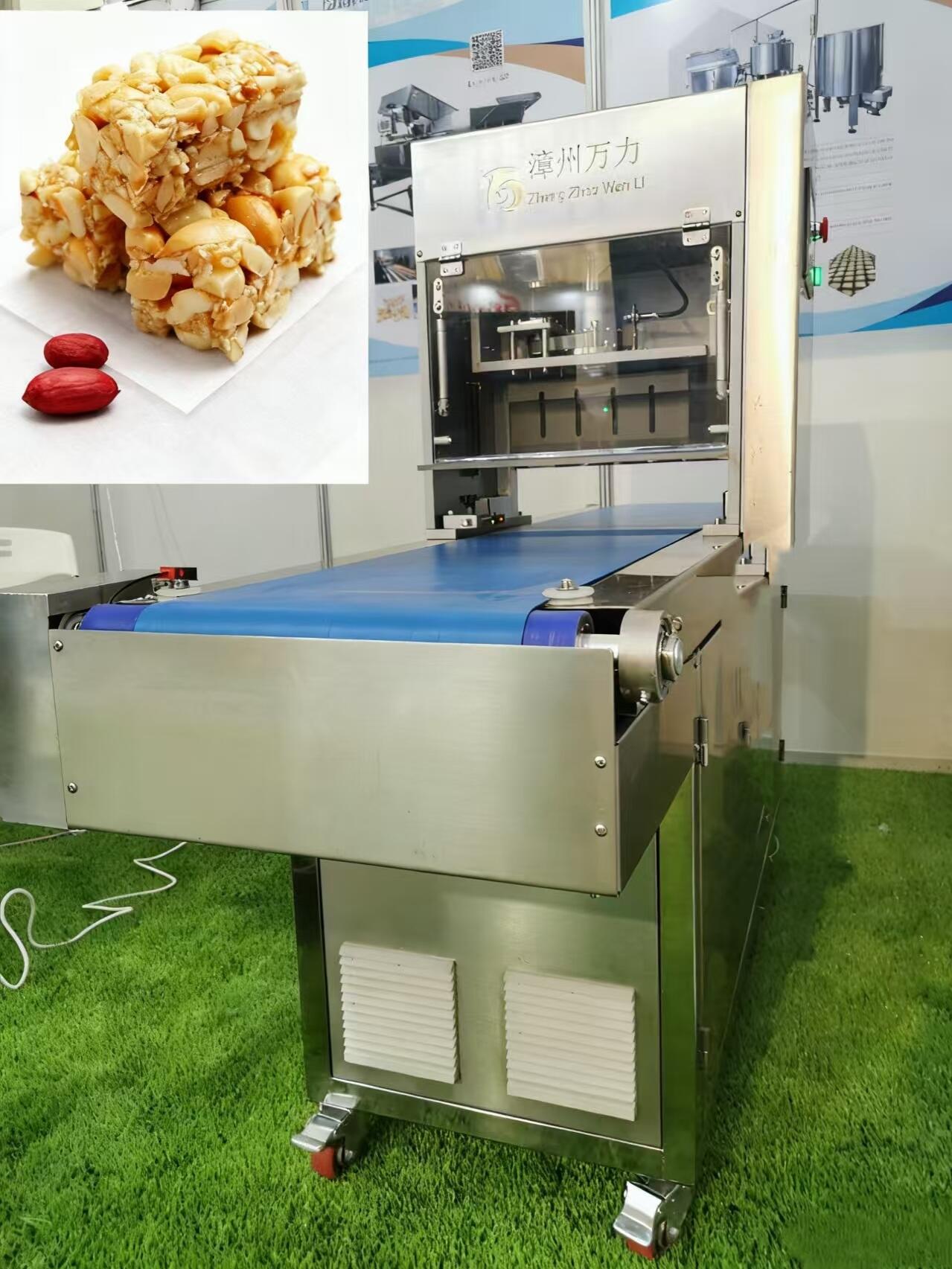

In today's rapidly developing confectionery manufacturing sector, cutting precision and production efficiency directly impact product market competitiveness and enterprise profitability. Zhangzhou Wanli, through its innovative ultrasonic cutting technology, introduces the industry-leading Wanli Ultrasonic Adjustable Peanut Brittle Cutter, providing intelligent cutting solutions for global confectionery manufacturers.

Innovative Ultrasonic Cutting Technology

Traditional candy cutting methods often encounter challenges such as product breakage, blade sticking, and low efficiency when processing peanut brittle. The Wanli Ultrasonic Adjustable Peanut Brittle Cutter utilizes high-frequency vibration technology, achieving non-contact cutting through 20,000-40,000 precise vibrations per second. This innovative cold-cutting process perfectly preserves the texture and structure of peanut brittle, ensuring smooth and even surfaces on every piece while effectively avoiding sugar splatter and raw material waste associated with traditional cutting methods.

Compared to conventional cutting techniques, this technology offers significant advantages:

· Pressure-Free Cutting: Avoids compression damage to brittle candies.

· Precision Adjustability: Cutting parameters can be flexibly adjusted based on product characteristics.

· Self-Cleaning: High-frequency vibration effectively prevents syrup adhesion to the blade.

· Hygienic and Efficient: Fully enclosed design complies with international food safety standards.

Intelligent System Design

The Wanli Ultrasonic Adjustable Peanut Brittle Cutter integrates multiple innovative technologies, demonstrating exceptional performance characteristics:

Adaptive Control System

Utilizing smart sensing technology, it monitors product hardness and thickness in real-time, automatically adjusting cutting parameters. The equipment supports an adjustable cutting speed of up to 60 cycles per minute, effortlessly handling peanut brittle products of various specifications.

User-Friendly Interface

Equipped with a high-definition touchscreen, the graphical interface is intuitive and easy to understand. The system supports three-level access management, ensuring the security and professionalism of production parameters. Operators can become proficient after brief training, significantly reducing the technical barrier.

Precision Adjustment System

The unique adjustable blade holder design allows for quick replacement of cutting dies in different specifications. The smart memory function can store multiple sets of product parameters, enabling rapid switching between different production requirements.

Outstanding Performance

The Wanli Ultrasonic Adjustable Peanut Brittle Cutter delivers significant benefits to users:

High-Efficiency Production Capacity

Adjustable cutting speeds meet varying production capacity needs, increasing production efficiency by over 50%.

Superior Product Yield

Product integrity rate exceeds 99%, effectively reducing raw material loss and optimizing operational costs.

Cost Optimization

Automated production can reduce labor costs by up to 70%,enhancing overall profitability.

Hygiene and Safety Design

Zhangzhou Wanli consistently upholds hygiene and safety as core design principles:

· Full stainless steel construction ensures equipment durability and hygiene.

· Modular design facilitates quick cleaning and maintenance.

· Comprehensive safety protection system fully safeguards operator safety.

· Compliance with international food machinery safety standards.

Intelligent Maintenance System

Wanli Group's innovative intelligent maintenance solutions include:

· Automatic operational status monitoring and early warning.

· Modular components designed for quick replacement.

· Remote technical support and fault diagnosis.

· Preventive maintenance reminder function.

Professional Technical Support

Wanli Group has established a comprehensive global service network:

· Personalized custom solutions.

· Professional operational training and guidance.

· 24-hour rapid response mechanism.

· Global spare parts supply guarantee.

FAQ

1. What types of peanut brittle products is the equipment suitable for?

The Wanli Ultrasonic Adjustable Peanut Brittle Cutter is suitable for various peanut brittle products, including traditional peanut brittle and sesame candy, offering excellent raw material adaptability. The adjustable design perfectly handles products with different hardness levels and thicknesses.

2. How long does it take to adjust the cutting specifications?

Utilizing the smart memory system, specification changes can be completed within 1 minute. The equipment supports storage for multiple sets of process parameters, ensuring production flexibility.

3. What should be noted for daily cleaning and maintenance?

Routine cleaning is recommended per shift, and the equipment provides smart maintenance reminders. The modular design allows core components to be disassembled quickly, with routine cleaning taking approximately 10 minutes.

4. What are the environmental requirements for the equipment?

It is suitable for standard food-grade production environments. Specific installation requirements can be confirmed on-site by professional technical personnel.

5. Is customization for special shapes supported?

Yes, customization for various special-shaped cuts is supported. Wanli Group provides professional design services to ensure personalized customer requirements are met.

Wanli Machinery is committed to providing innovative ultrasonic cutting solutions for global food enterprises. The Wanli Ultrasonic Adjustable Peanut Brittle Cutter, with its exceptional adaptability and intelligent design, sets a new technological benchmark for the confectionery manufacturing industry. We look forward to collaborating with you to jointly promote technological innovation and development in the confectionery sector.

Hot News

Hot News2025-12-14

2025-12-13

2025-12-12

2025-12-11

2025-12-10

2025-12-08