Contact Info

Unit 1011, Pingning Industrial, Longhai District, Zhangzhou City, Fujian Province

New York.

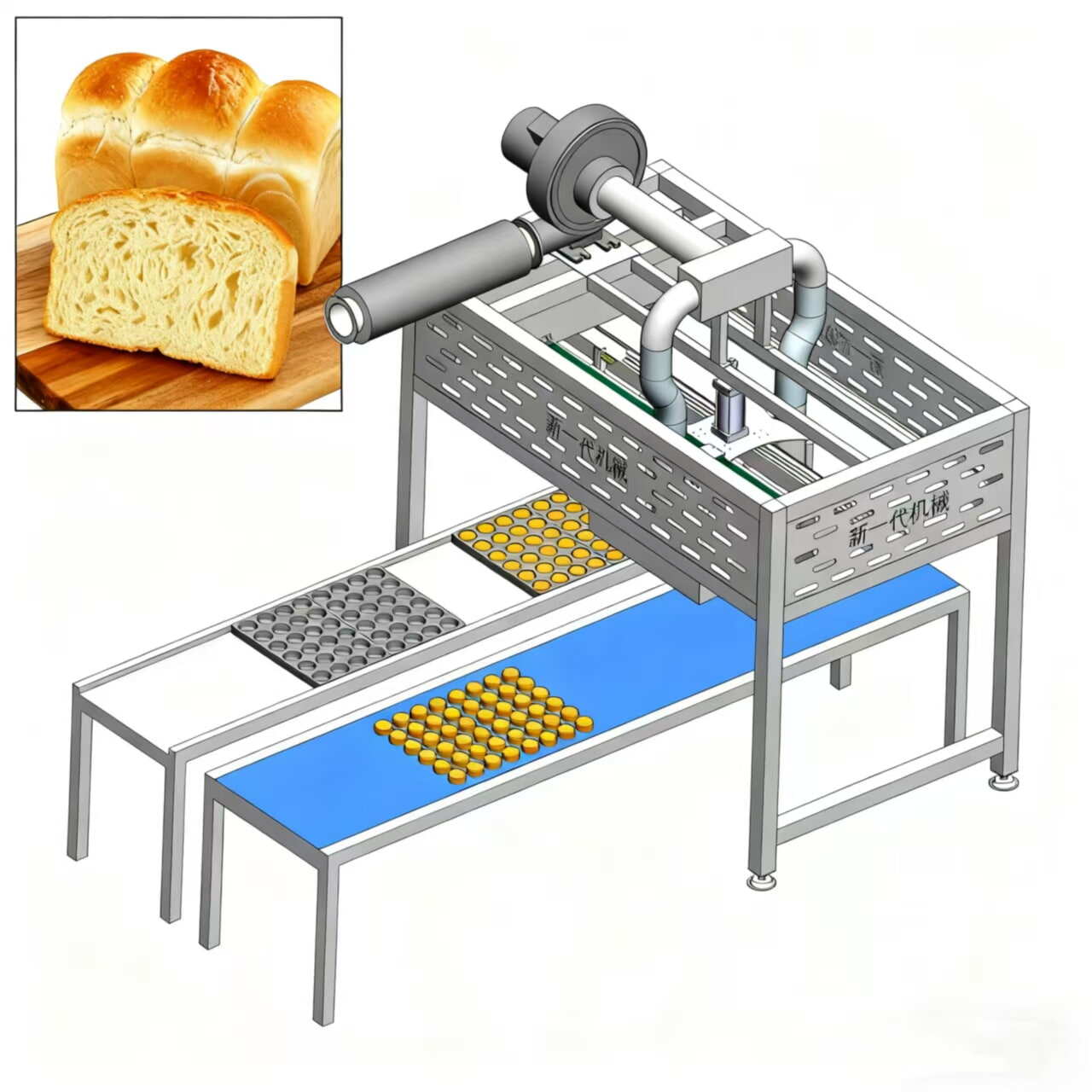

Traditional manual demolding methods often face challenges such as high product damage rates, significant hygiene risks, and low efficiency. The Wanli Bread and Cake Demolding Machine utilizes an advanced PLC programmable control system, achieving efficient and non-destructive demolding through precision vibration control and mechanical structure design. This innovative demolding method perfectly maintains the integrity of baked goods, ensuring each product achieves ideal demolding results.

Compared to traditional demolding methods, this technology offers significant advantages:

· Precision Control: Demolding success rate reaches 99.99%, substantially reducing product loss.

· Hygiene and Safety: Fully enclosed design minimizes direct human-food contact, complying with international food safety standards.

· High Efficiency and Stability: Demolding speed of 1-5 cycles per minute ensures smooth production flow.

· Energy Saving and Eco-Friendly: Electric or gas drive options available to meet different production environment needs.

Intelligent System Design

The Wanli Bread and Cake Demolding Machine integrates multiple intelligent technologies, showcasing exceptional performance characteristics:

Intelligent Control System

Utilizes advanced PLC and touchscreen coordinated control, featuring an intuitive and user-friendly interface. The system supports quick switching between various product parameters. Operators can become proficient after minimal training, significantly lowering the technical barrier.

Adaptive Adjustment System

Automatically adjusts demolding parameters based on product characteristics, easily handling molds of different materials and specifications. The unique vibration control system ensures stable demolding quality under various production conditions.

Data Management Platform

Integrates real-time production data recording,optimizing production processes through intelligent analysis. Equipment operational status is monitored in real-time, providing early warnings for potential issues to ensure production continuity.

Outstanding Performance

The Wanli Bread and Cake Demolding Machine delivers significant production benefits to users:

High Production Efficiency

Stable demolding rhythm ensures efficient production line operation, effectively boosting overall capacity.

Excellent Output Quality

Product integrity rate is significantly improved, with raw material waste substantially reduced.

Cost Optimization

Automated production reduces labor requirements by 60%, while simultaneously extending mold service life.

Hygiene and Safety Design

Zhangzhou Wanli always prioritizes hygiene and safety in design:

· Bright, clean equipment exterior; full stainless steel structure complies with food-grade standards.

· Enclosed operation effectively isolates external contamination.

· Automatic cleaning system ensures the equipment maintains a hygienic state long-term.

· Comprehensive safety protection devices fully ensure operator safety.

Intelligent Operation and Maintenance

Wanli Group adheres to a user-centric design philosophy:

· Simple, intuitive graphical operation interface for quick mastery.

· Intelligent diagnostic system monitors equipment status in real-time.

· Modular structural design for convenient and efficient maintenance.

· Remote technical support for rapid problem resolution.

Professional Technical Support

Wanli Group has established a comprehensive global service system:

· Personalized customized solutions.

· Professional operation training and guidance.

· 24-hour rapid response mechanism.

· Global spare parts supply network.

Frequently Asked Questions

1. Which product types is the equipment suitable for?

The Wanli Bread and Cake Demolding Machine is suitable for various baked products, including bread, cake, and pastries, offering excellent product adaptability. The special demolding technology perfectly handles molds of various materials.

2. How long does it take to change production specifications?

Utilizing the intelligent memory system, specification changes can be completed within 2 minutes. The equipment supports storage of multiple process parameter sets, ensuring production flexibility.

3. What should be noted for daily cleaning and maintenance?

Routine cleaning checks are recommended per shift. The equipment provides intelligent maintenance reminders. The modular design allows quick disassembly of core components, with routine cleaning taking only 15 minutes.

4. What are the environmental requirements for the equipment?

It is suitable for standard food-grade production environments. Specific installation requirements can be confirmed through on-site guidance by professional technicians.

5. Does it support custom mold requirements?

It supports various customization needs. Wanli Group provides professional technical consultation and sampling services.

Wanli Machinery is consistently committed to providing innovative automated solutions for global food enterprises. The Wanli Bread and Cake Demolding Machine, with its exceptional performance and intelligent design, sets a new technological benchmark for the baking industry. We look forward to collaborating with you to jointly promote the intelligent upgrade and development of the baking industry.

Hot News

Hot News2025-12-14

2025-12-13

2025-12-12

2025-12-11

2025-12-10

2025-12-08