Razumevanje osnova ultrazvučnog secanja šećera

Kako ultrazvučna vibracija poboljšava secanje šećera

Ultrasoničko sečenje slatkiša je najnovija tehnologija koja značajno povećava efikasnost sečenja slatkiša. Vibrate na visokim brzinama, što omogućava čisto sečenje bez oštećenja strukturne integriteta slatkiša. To smanjuje trenje i time otpor prilikom sečenja, a rezultat je vrlo precizno sečenje sa malo otpada. Neke studije su izvele da ultrasoničko sečenje, kada se odgovarajuće koristi, može smanjiti vreme proizvodnje za 20-30% u odnosu na ručne metode. Pregledano u Sjedinjenim Državama 10. februara 2020. Dostupno je kod Amazona kroz izvornog prodavca; Otkriveno je da kapacitet od 6 šalica Rosewill RHKT 15001, na Amazonu je promenjen u 1,8 L u mikrovalnom sigurnom loncu, ali je promenjen u 5,5 L kada je prodavac video vanjske sajtove. U krizi, ultrasonička agitacija pruža proizvođačima slatkiša mogućnost poboljšanja kvaliteta i brzine proizvodnje.

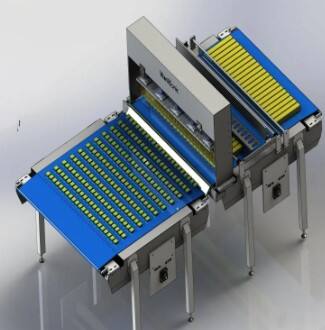

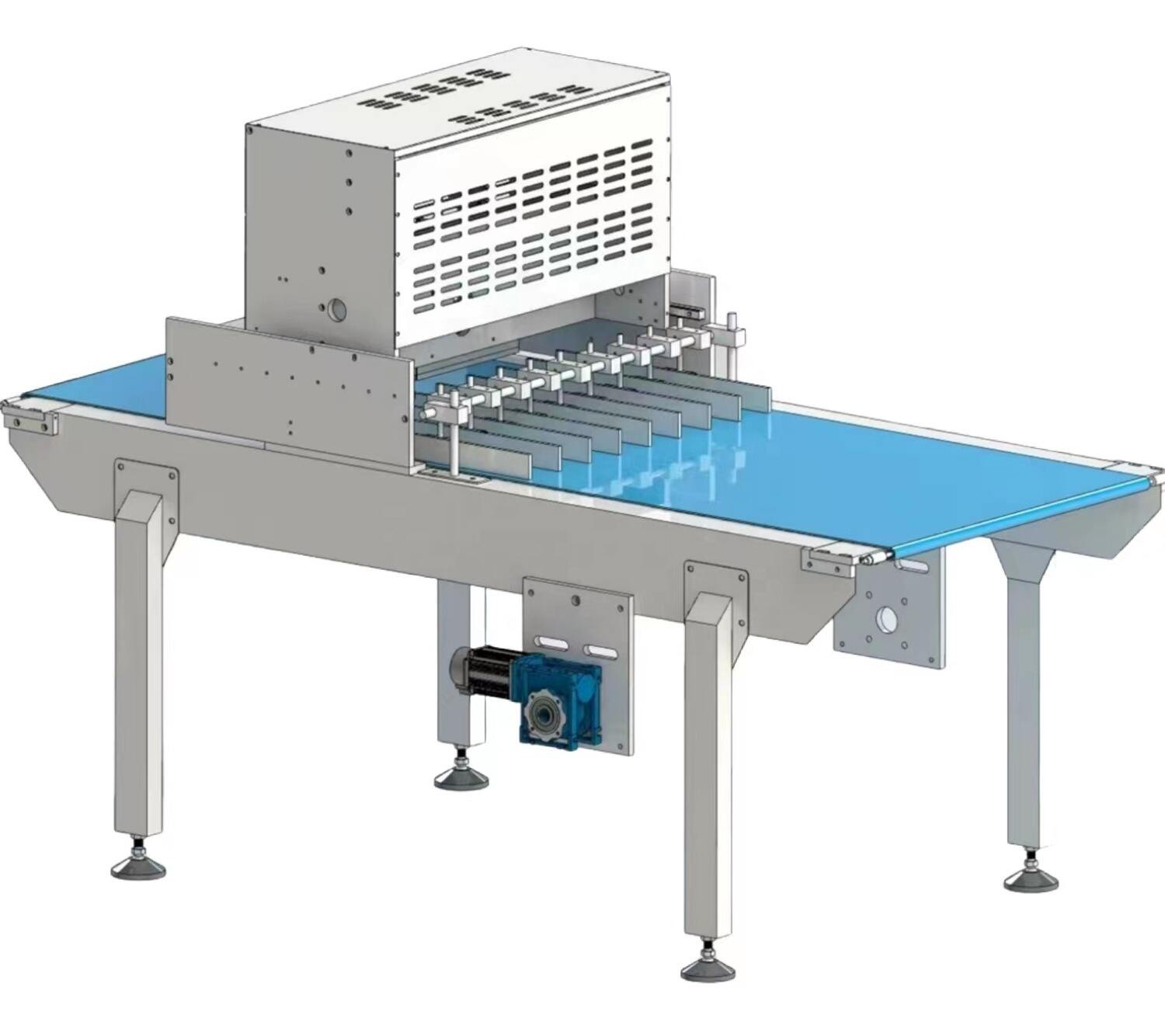

Ključni komponenti mašina za secanje šećera

Ultrasoničke mašine za secanje šećera imaju nekoliko ključnih delova koji omogućavaju njihov odličan rad. Na primer, ultrasonički pretvarač služi da prebaci električnu energiju u mehaničku vibraciju, što je neophodno za precizno secanje. Noževe za secanje prilagođavaju se različitim vrstama šećera i igraju osnovnu ulogu u postizanju najboljih performansi; pravi izbor materijala i oblika tih noževa je odlučujući za efikasnost. Takođe, upravljački sistemi održavaju frekvenciju i amplitudu, čime se osigurava jednoliko secanje pri različitim vrstama šećera. Dobro kalibriranje ovih sistema osigurava konstantnu i visoku proizvodnju te širok spektar upotrebe za proizvodnju šećera. Uvođenjem ovih elemenata poboljšavaju se performanse i dostižu se bolji rezultati.

Top 5 grešaka pri korišćenju ultrazvukovnog sečenja slatkiša koje treba izbeći

Netačno poravnanje i kalibracija noževa

Za kvalitetne sečeve slatkiša je vrlo važno da se češlje drže poravnate i kalibrisane tačno. Pogrešna registracija koja uzrokuje da se nepoželjne dijelovi osekuju ili diru, štedruljući kvalitet proizvoda i uzrokujući otpad, takođe se spominje. Morate da osigurate da se testiraju i kalibrišu redovito kako biste minimizovali greške pri secanju — prema preporukama većine proizvođača sečalica, to treba raditi barem jednom nedeljno. Čuvanjem ovog rasporeda, faktor transporta je zadovoljen i efikasnost proizvodnje ne pada zbog sastava slatkiša.

Заборављавање контроле температуре у зонама за сечење

Upravljanje temperingom/temperaturom prilikom ultrazvukovog secanja u slatkisištu takođe utiče na lepljivost slatkiše kada se seče. Više temperature rezultuju prelomljenim, neuređenim ili toplim slatkicama, što ih čini manje željenim. 'Optimalni' opsezi temperature treba odrediti za povećano sposobnost secanja i bolji stan slatkice. Dobrom kontrolom temperature, ono što ćete dobiti je uvijek savršeni proizvod koji ispunjava očekivanja potrošača.

Korišćenje nošenih ili oštećenih sečnih željeza

Pokretanje starih ili oštećenih sečnih žileva je jedna od najčešćih grešaka koje mogu povećati produktivnost i ukupnu kvalitetu secanja. Lošo održavane žileve prave nejednake sečeve i mogu dovesti do skupih zaustava mašine koji će zaustaviti produktivnost vaše linije proizvodnje. Važno je da jedinice redovno provere i zamene žileve kako bi mašina nastavila da radi na vrhunskom nivou i kako bi pojedinačne komade bile konzistentne.

Neposledovno čišćenje koje dovodi do nagomilavanja ostataka

Važno je da se čistočne procedure drže konzistentnim kako bi se izbeglo nagomilavanje ostataka, poput preostalog šećera, što može uzrokovati probleme sa lepljenjem i uticati na izgled krajnjeg proizvoda. Ako se rezna mašina ne čisti odgovarajuće, to može uzrokovati higijenske probleme i smanjiti životni vek opreme. Redovne čiscenja su neophodna da bi se mašine držale u dobroj radnoj uslovu i proizvodile savršene slatice svaki put.

Loša upravljanja brzinom režanja za različite slatke

Poznavanje i prilagođavanje brzine režanja za različite vrste slatkiša je neophodno kako bi se izbegle greške kao što su ružni ivici i neprecizno režanje. Slatkiši se mnogo razlikuju u odnosu na brzinu režanja pri kojoj se dobija željeni rezultat, a primena ove metode na brzini znatno višoj ili nižoj od optimalne će rezultirati manje odličnim radnim rezultatima. Istraživanje i dokumentovanje najboljih brzina za svaki tip slatkiša može biti ključan faktor uspeha u operacijama i kvalitetu krajnjeg proizvoda. Stizanjem do optimalne brzine, proizvođači slatkiša će biti u mogućnosti da proizvedu slatkiše koji uvijek ispunjavaju najviša standarda industrijalnog sektora.

Optimizacija podešavanja mašine za proizvodnju slatkiša

Kalibriranje podešavanja frekvencije i amplitude

Važno je pravilno prilagoditi frekvenciju i amplitudu u ultrazvučnim mašinama za sekanje šećera, jer će u suprotnom vibracija isklizati i postati će teško pravilno seci. "Obično je pravilo da ćete želeli promeniti to periodično, zavisno od vrste šećera koji je u pitanju," rekao je Ratliff. Na primer, različite formulacije mogu biti najefikasnije sečene na različitim frekvencijama. Čuvanjem ovih podešavanja u dobrom stanju, možete da osigurate da vaš ultrazvučni uređaj izbacuje odgovarajući tip i količinu energije da bi se sačuvala brzina i tačnost secanja.

Poravnavanje žileza za precizna rezanja

Pravilno praćenje noža ključ je za maksimalnu efikasnost secanja u velikim fabrikama šećera. Dobro poravnjani nož smanjuje preterano nosnju, što bi bilo uzrok većim troškovima i više otpada kao rezultat otpadne materije. Kvalitet proizvoda se poboljšava, budući da se tokom secanja održava preciznost, što dovodi do manje gubitka materije i povećanja proizvodnog izlaza kompanija.

Stvaranje stabilnih environskih uslova

Budući da tako mnogo iz procesa zavisi od kontrolisanih okruženja, prava kontrola okruženja je ključna u pogledu sastava slatkiša, vlažnosti i temperature. Konstantni nadzor i kontrola temperature utiče na masu slatkiša, osiguravajući jednoliko sečenje slatkiša i izbjegavajući varijacije u efikasnosti proizvodnje. Na primer, regulisanje ambijentalne temperature može uticati na viskoznost mešavine slatkiša, a kontrola vlažnosti može uticati na vreme zrelosti. Stoga, kada su postavljene stabilne uslove okruženja, dobra upravljanja opštom progresijom proizvodnje je osigurana.

Strategije preventivnog održavanja

Planirani postupci dubinskog čišćenja

Imajte na umu da, ako koristite ultrazvukovu mašinu za sečenje šećera, redovito duboko čišćenje je neophodno za održavanje te mašine u dobroj formi i visokoefikasnom stanju. Redovito čišćenje nagomilanih materijala osigurava dugogodišnji život i maksimalnu performansu opreme. Postoji stalna rasprava o frekvenciji čišćenja unutrašnjosti mašine za vrele piće, pri čemu mnogi u industriji smatraju da je dvoednevni pristup najboljom praksom - što znači da smanjuje problematike u radu i poboljšava efikasnost mašine. Izvršavanjem redovnih postupaka čišćenja, proizvođači će održati svoju opremu u vrhunskom radnom stanju, time smanjujući neaktivno vreme i povećavajući produktivnost.

Provere vibracionog sistema

Redovne provere vibracijske jedinice su važne kako bi se uhvatile sve one skrivene probleme prije nego što postanu veliki problem. Mogućnost identifikacije i reagiranja na probleme u ranoj fazi može rezultirati značajnim štednjama u odnosu na održavanje — do 15%-20% prema industrijalnim izveštajima. Održavanje vibracijskog sistema može dužiti korisni život opreme, a korisno je za poboljšanje glatkog tijeka reza, što je ključno kada je cilj proizvodnja kvalitetnog PdCcUt.

Метрике за снимање перформанси

Pratite performanse kao značajno sredstvo za prepoznavanje rada ultrazvučnih mašina za sečenje slatkiša. Pratiti ove podatke na dnevnom nivou ne samo što pomaže u identifikovanju oblasti koje mogu da se unaprede, već i vodi do značajne štednje vremena na dužem roku. Analitičari savetuju jaču dokumentaciju, jer će omogućiti brzu procenu odstupanja u performansama i olakšati reagovanje u odgovarajućem vremenskom periodu, čime doprinosi proaktivnoj disciplini održavanja koja drži proizvodnju na cilju dok maksimizuje ukupnu performansu alata.

Rešavanje uobičajenih problema secanja

Razrešavanje problema deformacije slatkiša

Deformacije šećera često se dešavaju i mogu značajno uticati na kvalitet krajnjeg proizvoda. Prilikom rešavanja problema, neophodno je imati znanje o tome šta je uzrokovalo probleme (bilo da su to prekomerna toplina ili pritisak) kako bi se problemi mogli rešiti. Kada dođe do deformacije, često će vam savetovati da prilagodite postavke topline ili zamijenite otuple žile kako biste rešili ove probleme. Takve promene su neophodne kako bi se održao struktura šećera, kao i kako bi se povećao ekonomski učinak proizvodnje. Ne gubеći iz bunе ovih razmatrаnjа vodi do stаbilnog i kваlitetnog rezultаtа, smanjenje otpаdа i efikаsnо korisćenje vremеnа proizvodnje.

Rešavanje izazova lepljenja željezaka

Prilaganje kliznog štapa može biti ozbiljan problem, posebno u procesu proizvodnje, i neizbežno uzrokuje zaustavljanje linije. Ovaj problem se može prevzeti izborom odgovarajućeg mašinskog ulja ili promenom brzine rada. Takođe, ne zaboravite da pregledate mašinske priručnike za preporučene načine mašinske smaživanja kako biste spreventovali skuplje štete ili lošu performansu mašine. Klizni štapovi koji se slobodno kreću bez veće otpornosti ne štede samo vaše vreme, već održavaju stalnu radnju proizvodnje – manje stajanja, bolji rezultat.

Popravljanje neravnomjernih rezanih uzoraka

Takve prekidane linije reza obično su rezultat neuskladjenosti ili neprecizne kalibracije žileva ili povezanih uređaja i često moraju biti ispravljeni skoro odmah da bi se izbeglo zaustavljanje rada. Revizije i provere kalibracije na redovitim intervalima su ključne kako bi se ove probleme istaknule i ispravile prije nego što dođu do eskalacije. Redovna kalibracija osigurava da mašina radi sa svojom maksimalnom sposobnošću, stvarajući ravne reze koji odgovaraju industrijskim standardima. Proaktivni pristup omogućava proizvođačima da smanje defektne proizvode i optimiziraju operativnu učinkovitost, što vodi do povećane zadovoljnosti kupaca i većih dobiti na dugom roku.

Česta pitanja o ultrazvučnom sečenju šećera

Šta je ultrazvučna vibracija u sečenju šećera?

Ultrazvučna vibracija u sečenju šećera podrazumева koristenje visokofrekventnih zvučnih talasa kako bi se omogućilo precizno i čisto sečenje, smanjujući trenje i održavajući strukturnu integritet šećera.

Zašto je poravnanje žile važno u mašinama za sečenje šećera?

Tačna poravnanja češlja je ključna zato što osigurava jednolike sečeve i smanjuje otpad, pomagajući u održavanju visokog kvaliteta proizvodnje slatkiša i poboljšavajući operativnu efikasnost.

Kako temperatura utiče na ultrazvučno sečenje slatkiša?

Temperatura utiče na lepljivost slatkiša tijekom sečenja. Potrebna je odgovarajuća kontrola kako bi se održao oblik i izgled slatkiša, sprečavajući deformacije tijekom procesa sečenja.

Šta su uobičajene prakse u održavanju mašina za ultrazvučno sečenje slatkiša?

Uobičajena praksa održavanja uključuje redovito duboko čišćenje, inspekcije vibracijskog sistema i praćenje performansi metrika kako bi se osigurala optimalna efikasnost i dugotrajnost mašine.

Kako riješiti probleme sa lepljenjem češlja u proizvodnji slatkiša?

Lepljenje češlja se često može riješiti koristeći odgovarajuće lužnjake i prilagođavajući brzinu rada, kao i osiguravajući redovite provjere održavanja i kalibracije.

Садржај

- Razumevanje osnova ultrazvučnog secanja šećera

- Top 5 grešaka pri korišćenju ultrazvukovnog sečenja slatkiša koje treba izbeći

- Optimizacija podešavanja mašine za proizvodnju slatkiša

- Strategije preventivnog održavanja

- Rešavanje uobičajenih problema secanja

-

Česta pitanja o ultrazvučnom sečenju šećera

- Šta je ultrazvučna vibracija u sečenju šećera?

- Zašto je poravnanje žile važno u mašinama za sečenje šećera?

- Kako temperatura utiče na ultrazvučno sečenje slatkiša?

- Šta su uobičajene prakse u održavanju mašina za ultrazvučno sečenje slatkiša?

- Kako riješiti probleme sa lepljenjem češlja u proizvodnji slatkiša?