Ultrasonic Շոկոլադային Սահմանման Հիմնական Սկզբունքների Կարგավորում

Ինչպես Ultrasonic Տատանումը Ավելացնում է Շոկոլադային Սահմանման

Քաղցրավենիքների ուլտրաձայնային կտրումը ժամանակակից տեխնոլոգիա է, որը զգալիորեն բարձրացնում է քաղցրավենիքի կտրման արդյունավետությունը: Այն թրթռում է բարձր արագությամբ, ուստի նպաստում է կոկիկ կտրվածքներին՝ առանց վնասելու քաղցրավենիքի կառուցվածքային ամբողջականությունը: Սա նվազեցնում է շփումը և, հետևաբար, կտրման դիմադրությունը, և հանգեցնում է բարձր ճշգրտության կտրման՝ քիչ թափոններով: Որոշ ուսումնասիրություններ ցույց են տվել, որ ուլտրաձայնային կտրումը, երբ օգտագործվում է ճիշտ, կարող է կրճատել արտադրության ժամանակը 20-30%-ով՝ ձեռքի մեթոդների համեմատ: Ավելի քիչ: Վերանայվել է Միացյալ Նահանգներում 2020 թվականի փետրվարի 10-ին: Հասանելի է Amazon-ում՝ սկզբնական վաճառողի միջոցով. պարզվել է, որ Rosewill RHKT 15001-ի 6 բաժակ տարողությունը Amazon-ում փոխվել է 1,8 լիտրի՝ միկրոալիքային վառարանում օգտագործելու համար անվտանգ տարայի մեջ, բայց փոխվել է 5,5 լիտրի, երբ վաճառողը տեսել է արտաքին հատվածները: Ամփոփելով՝ ուլտրաձայնային խառնումը քաղցրավենիքի արտադրողներին հնարավորություն է տալիս բարելավել արտադրության որակը և արագությունը:

Քաղցկերի Կտրման Մաքինաների Հիմնական Komponentner

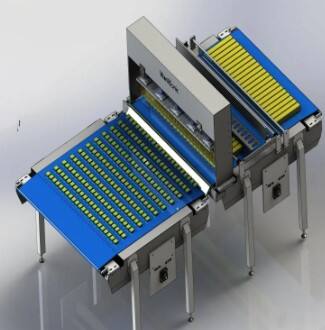

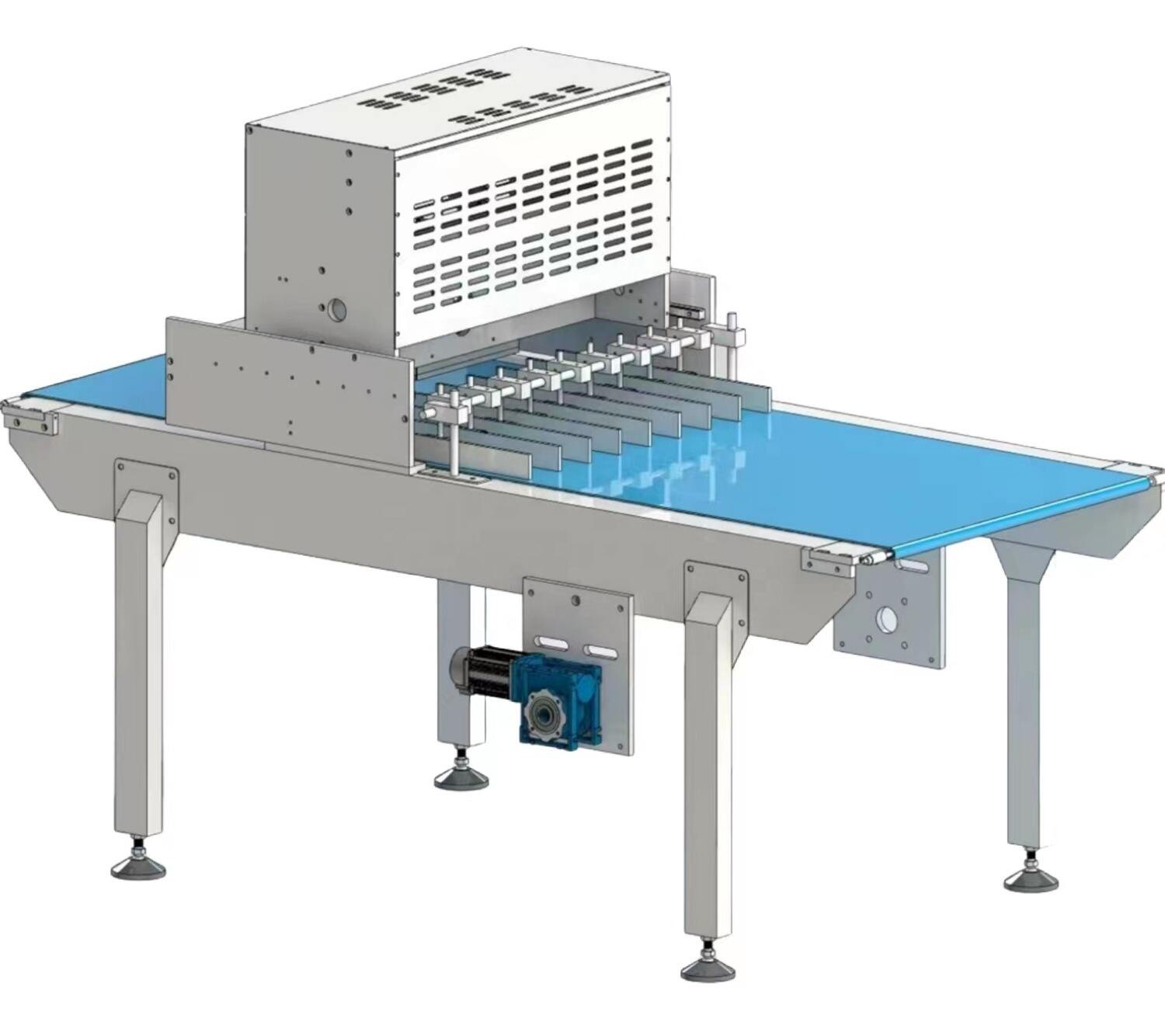

Ուլտրաձայնային քաղցրավենիքի կտրող մեքենաներն ունեն մի քանի կարևոր մասեր, որոնք թույլ են տալիս դրանց այդքան լավ աշխատել: Օրինակ՝ ուլտրաձայնային փոխարկիչը ծառայում է էլեկտրական էներգիան մեխանիկական թրթռման վերածելուն, որն անփոխարինելի է ճշգրիտ կտրելու համար: Կտրող շեղբերը հատուկ են տարբեր տեսակի քաղցրավենիքի համար և հիմնարար դեր են խաղում լավագույն արդյունքներ ստանալու համար. նյութի և շեղբերի ձևի ճիշտ ընտրությունը կարևոր դեր են խաղում արդյունավետության առումով: Ավելին, կառավարման համակարգերը պահպանում են հաճախականությունը և ամպլիտուդը, հետևաբար՝ կտրման միատարրությունը՝ քաղցրավենիքի տարբեր տեսակների միջև: Այս համակարգերում լավ կարգաբերումը ապահովում է հաստատուն և բարձր մակարդակի արտադրողականություն և քաղցրավենիքի արտադրության լայն կիրառություն: Այս տարրերի ընդունումը բարելավում է արտադրողականությունը և ապահովում ավելի լավ արդյունքներ:

Վերջին 5 սխալ սանդվիչ սահքի ultrasonic տեխնոլոգիայի մեջ՝ որոնց հեռացումը պետք է խուսափել

Սխալագործված կոտորակի համակարգում և կալիբրացիայում

Քաղցրավենիքի որակյալ կտրվածքների համար շատ կարևոր է շեղբերը ճիշտ դասավորված և կարգավորված պահելը: Նաև նշվում է սխալ գրանցումը, որը հանգեցնում է ոչ նախշավոր մասերի կտրման կամ պատռման, վատթարացնելով ապրանքի որակը և հանգեցնելով թափոնների կրճատման: Դուք պետք է համոզվեք, որ դրանք պարբերաբար ստուգվում և կարգավորված են՝ կտրման սխալները նվազագույնի հասցնելու համար. կտրիչների արտադրողների մեծ մասի առաջարկություններում դա առնվազն շաբաթը մեկ անգամ է: Այս ժամանակացույցին հետևելով՝ փոխադրման գործոնը բավարարվում է, և արտադրության արդյունավետությունը չի նվազում քաղցրավենիքի բաղադրության հաշվին:

Տեմպերատուրային կառավարման անհամարժեքություն սառչափման โซնաներում

Քաղցրավենիքի բիզնեսում ուլտրաձայնային կտրման ժամանակ կոփումը/ջերմաստիճանի կարգավորումը նույնպես ազդում է քաղցրավենիքի մածուցիկության վրա կտրման ժամանակ: Բարձր ջերմաստիճանները հանգեցնում են կոտրված, ձևափոխված կամ հալված քաղցրավենիքի, ինչը այն դարձնում է պակաս ցանկալի: Կտրման ունակության բարձրացման և քաղցրավենիքի ավելի լավ վիճակի համար պետք է որոշվեն «օպտիմալ» ջերմաստիճանային միջակայքեր: Լավ ջերմաստիճանի կարգավորման դեպքում դուք միշտ կստանաք կատարյալ արտադրանք, որը կբավարարի սպառողի սպասելիքները:

Օգտագործում են արդեն անձրևացած կամ վարդագրված կտրող սանդղակներ

Հին կամ վնասված կտրող շեղբերի օգտագործումը ամենատարածված սխալներից մեկն է, որը կարող է բարձրացնել արտադրողականությունը և կտրվածքների ընդհանուր որակը: Վատ պահպանված շեղբերը անհավասար կտրվածքներ են առաջացնում և կարող են հանգեցնել մեքենայի թանկարժեք անջատումների, ինչը կկանգնեցնի ձեր արտադրական գծի արտադրողականությունը: Կարևոր է, որ սարքավորումները պարբերաբար ստուգեն և փոխարինեն շեղբերը, որպեսզի մեքենան շարունակի աշխատել առավելագույն արդյունավետությամբ, և առանձին մասերը համապատասխանեն միմյանց:

Անհամարեցված լքում, որը նำում է մնացորդների ավելացմանը

Կարևոր է պահպանել մաքրման ընթացակարգերի հետևողականությունը՝ մնացորդային շաքարի, օրինակ՝ մնացորդային մնացորդների կուտակումից խուսափելու համար, որոնք կարող են կպչունության խնդիրներ առաջացնել և ազդել վերջնական արտադրանքի տեսքի վրա: Եթե կտրող մեքենան պատշաճ կերպով չի մաքրվում, դա կարող է սանիտարական խնդիրներ առաջացնել և կրճատել սարքավորումների կյանքը: Մեքենաները լավ աշխատանքային վիճակում պահելու և ամեն անգամ կատարյալ կոնֆետներ ստանալու համար անհրաժեշտ են կանոնավոր մաքրումներ:

Սխալ կառուցվածքի վարումը տարբեր սառույցների համար

Տարբեր տեսակի քաղցրավենիքի կտրման արագությունները իմանալը և կարգավորելը պարտադիր է՝ սխալներից, ինչպիսիք են կոպիտ եզրերը և սխալ կտրվածքները, խուսափելու համար: Քաղցրավենիքները մեծապես տարբերվում են կտրման այն կոնկրետ արագությամբ, որով ստացվում է ցանկալի կտրման արդյունք, և գյուտի կիրառումը այդ օպտիմալ արագությունից զգալիորեն բարձր կամ ցածր արագությամբ կհանգեցնի օպտիմալից ցածր շահագործման արդյունքների: Քաղցրավենիքի յուրաքանչյուր տեսակի համար լավագույն արագությունների ուսումնասիրությունը և փաստաթղթավորումը կարող է լինել գործողությունների և վերջնական արտադրանքի որակի հաջողության գրավականը: Համընթաց քայլել՝ սովորելով, թե ինչպես արդյունավետորեն վերահսկել կտրման արագությունը, քաղցրավենիքի արտադրողները կկարողանան արտադրել քաղցրավենիք, որը միշտ համապատասխանում է արդյունաբերության ամենաբարձր չափանիշներին:

Համարժեք մեքենային սահմանափակումը քաղցալի արտադրության համար

Քաiasi և ամպլիտուդի կարգավորումների սահմանում

Կարևոր է ճիշտ կարգավորել ուլտրաձայնային քաղցրավենիք կտրող մեքենաների հաճախականությունը և ամպլիտուդը, հակառակ դեպքում թրթռումը կվերանա, և դժվար կլինի ճիշտ կտրել: «Սովորաբար կանոնն այն է, որ դուք պետք է պարբերաբար փոխեք այն՝ կախված նրանից, թե ինչ տեսակի քաղցրավենիք է խոսքը», - ասաց Ռատլիֆը: Օրինակ, տարբեր բանաձևերը կարող են առավել արդյունավետ կերպով կտրվել տարբեր հաճախականություններով: Այս կարգավորումները լավ կարգավորված պահելով՝ դուք կարող եք ապահովել, որ ձեր ուլտրաձայնային սարքը արտանետում է էներգիայի աղտոտիչների ճիշտ տեսակը և քանակը՝ կտրման արագությունն ու ճշգրտությունը պահպանելու համար:

Կորերի համաչափ դիրքավորումը ճշգրտ կորուստների համար

Սայրերի ճիշտ հետևողականությունը մեծ ծավալի քաղցրավենիքի գործարաններում կտրման առավելագույն արդյունավետության գրավականն է: Սայրերի լավ դասավորվածությունը նվազեցնում է չափազանց մաշվածությունը, ինչը կարող է հանգեցնել ավելի բարձր արժեքի և ավելի շատ ջարդոնի՝ թափոնների հետևանքով: Արտադրանքի որակը բարելավվում է, քանի որ կտրման ընթացքում պահպանվում է ճշգրտությունը, ինչը հանգեցնում է նյութական կորստի նվազմանը և ընկերությունների կողմից արտադրության ծավալի աճի:

Ստաբիլ միջավայրի պայմանների ստեղծում

Քանի որ գործընթացի մեծ մասը հիմնված է վերահսկվող միջավայրի վրա, անհրաժեշտ է պատշաճ շրջակա միջավայրի վերահսկողություն՝ քաղցրավենիքի կազմի, խոնավության և ջերմաստիճանի առումով: Ջերմաստիճանի մշտական հսկողությունը և վերահսկողությունը, քանի որ այն ազդում է քաղցրավենիքի զանգվածի վրա, ապահովում է քաղցրավենիքի միատարր կտրումը և կանխում արտադրության արդյունավետության տատանումները: Օրինակ, շրջակա միջավայրի ջերմաստիճանի կարգավորումը կարող է ազդել քաղցրավենիքի խառնուրդի մածուցիկության վրա, իսկ խոնավության վերահսկողությունը կարող է ազդել կարծրացման ժամանակի վրա: Հետևաբար, երբ կայուն շրջակա միջավայրի պայմաններ են ստեղծվում, ապահովվում է արտադրության ընդհանուր առաջընթացի լավ կառավարում:

Պահպանագրական Տարբերակներ

Կարգավորված Գնահատված Մաքրություն

Հիշե՛ք, որ եթե օգտագործում եք ուլտրաձայնային քաղցրավենիք կտրող մեքենա, կանոնավոր խորը մաքրումը այդ մեքենան լավ վիճակում և բարձր արդյունավետությամբ պահելու անբաժանելի մասն է կազմում: Կուտակումների կանոնավոր մաքրումը երաշխավորում է սարքավորումների երկարակեցությունը և լավագույն աշխատանքը: Մշտական բանավեճեր կան տաք ըմպելիքների մեքենայի ներսի մաքրման հաճախականության շուրջ, երկշաբաթյա մոտեցումը համարվում է ոլորտի շատերի կողմից լավագույն պրակտիկա, ինչը նշանակում է, որ այն նվազեցնում է շահագործման խափանումները և բարելավում մեքենայի արդյունավետությունը: Կանոնավոր մաքրման պրակտիկա կատարելով՝ արտադրողները կպահպանեն իրենց սարքավորումները լավագույն աշխատանքային վիճակում, այդպիսով նվազեցնելով ցանկացած անսարքություն և բարձրացնելով արտադրողականությունը:

Վիբրացիոն համակարգի ստորագրություններ

Թրթռման համակարգի կանոնավոր ստուգումները կարևոր են բոլոր այդ թաքնված խնդիրները հայտնաբերելու համար, նախքան դրանք լուրջ խնդիր դառնալը: Խնդիրները վաղ փուլում հայտնաբերելու և դրանց վրա գործողություններ ձեռնարկելու ունակությունը կարող է հանգեցնել սպասարկման ծախսերի զգալի խնայողության՝ մինչև 15%-20%՝ ըստ արդյունաբերության հաշվետվությունների: Թրթռման համակարգի պահպանումը կարող է երկարացնել սարքավորումների օգտակար կյանքը, և այն օգտակար է կտրման գործընթացի սահուն ընթացքը բարելավելու համար, ինչը կարևոր է, երբ նպատակը որակյալ PdCcUt-ի արտադրությունն է:

Գրանցման կատարողականի չափանիշներ

Արդյունավետության մոնիթորինգը կարևոր միջոց է ուլտրաձայնային քաղցրավենիք կտրող մեքենաների աշխատանքը ճանաչելու համար: Այս տվյալների ամենօրյա հետևումը ոչ միայն օգնում է բացահայտել այն ոլորտները, որոնք կարող են բարելավման կարիք ունենալ, այլև երկարաժամկետ հեռանկարում հանգեցնում է ժամանակի մեծ խնայողության: Վերլուծաբանները խորհուրդ են տալիս ունենալ ամուր փաստաթղթավորում, քանի որ դա թույլ կտա արագ գնահատել արդյունավետության տատանումները և կհեշտացնի ժամանակին արձագանքելը, այդպիսով նպաստելով կանխարգելիչ սպասարկման կարգապահությանը, որը պահպանում է արտադրությունը նպատակային մակարդակի վրա՝ միաժամանակ առավելագույնի հասցնելով մեքենայի ընդհանուր արդյունավետությունը:

Ելակետների հանդիսացող խնդիրների լուծում

Կանդի փոխարինման խնդիրների լուծում

Քաղցրավենիքի դեֆորմացիաները հաճախ են տեղի ունենում և կարող են մեծապես ազդել վերջնական արտադրանքի որակի վրա: Խնդիրները լուծելու համար անհրաժեշտ է իմանալ, թե ինչն է առաջացրել խնդիրները (անկախ նրանից՝ դա չափազանց ջերմությունն էր, թե ճնշումը), եթե խնդիրները կարող են լուծվել: Երբ դեֆորմացիա է տեղի ունենում, նրանք հաճախ խորհուրդ են տալիս փոփոխել ջերմաստիճանի կարգավորումները կամ փոխարինել բթացած շեղբերը՝ այդ խնդիրները լուծելու համար: Նման փոփոխությունները անհրաժեշտ են ինչպես քաղցրավենիքի կառուցվածքը պահպանելու, այնպես էլ արտադրության տնտեսական արդյունավետությունը բարձրացնելու համար: Այս նկատառումները չմոռանալը հանգեցնում է կայուն և որակյալ արդյունքի, թափոնների կրճատման և արտադրական ժամանակի արդյունավետ օգտագործման:

Ստիգող սանի խնդիրների լուծում

Սայրի կպչունությունը կարող է լուրջ խնդիր լինել, հատկապես արտադրական գործընթացում, և անխուսափելիորեն հանգեցնում է գծի կանգառի: Այս խնդիրը կարելի է հաղթահարել՝ ընտրելով ճիշտ քսանյութ կամ փոխելով աշխատանքի արագությունը: Բացի այդ, մի մոռացեք ստուգել մեքենայի ձեռնարկները՝ խորհուրդ տրվող քսանյութի համար՝ թանկարժեք վնասներից կամ մեքենայի վատ աշխատանքից խուսափելու համար: Ազատ շարժվող սայրերը, որոնք մեծ դիմադրության չեն ենթարկվում, ոչ միայն խնայում են ձեր ժամանակը, այլև ապահովում են արտադրական գծի կայուն աշխատանքը՝ ավելի քիչ պարապուրդի ժամանակ, ավելի լավ արտադրողականություն:

Անկանոն սահքման արտապատկերների արտակարգում

Նման ընդհատվող կտրման գծերը սովորաբար շեղբերի կամ դրանց հետ կապված սարքավորումների անհամապատասխանության կամ սխալ տրամաչափման արդյունք են և հաճախ պետք է շտկվեն գրեթե անմիջապես, եթե ցանկանում եք խուսափել անսարքությունից: Կանոնավոր ժամանակահատվածներում աուդիտներն ու տրամաչափման ստուգումները կարևոր են այս խնդիրները բացահայտելու և շտկելու համար, նախքան դրանք սրվեն: Պարբերական տրամաչափումը ապահովում է, որ մեքենան կաշխատի իր առավելագույն հզորությամբ՝ ստեղծելով հավասար կտրվածքներ, որոնք համապատասխանում են արդյունաբերության չափանիշներին: Նախաձեռնողական մոտեցումը թույլ է տալիս արտադրողներին կրճատել թերի արտադրանքը և օպտիմալացնել գործառնական արդյունավետությունը, ինչը երկարաժամկետ հեռանկարում հանգեցնում է հաճախորդների գոհունակության բարձրացմանը և ավելի բարձր շահույթի:

Հարցերի և պատասխանների մասին .ultrasonic ստիպում կանդի:

Ինչ է ultrasonic տատանումը կանդի ստիպման ժամանակ։

Ultrasonic տատանումը կանդի ստիպման ժամանակ ներառում է high-frequency звучային ալիքների օգտագործումը՝ ճշգրիտ և կարևոր ստիպեր ստանալու համար, նվազեցնելով հարվածությունը և պահելով կանդի կառուցումը։

Դիրքի դիրքը ինչու է կարևոր կանդի ստիպման մաքինաներում։

Ճիշտ սահքի դիրքը կարևոր է, քանի որ այն garantees հավասարաչափ սահքեր և մինիմիզում է թացքի քանակը, օգնում է պահպանել բարձր որակի սանդվիչի տուգանքը և ավելացնում է գործառույթային արդյունավետությունը:

Ինչպես ազդում է ջերմությունը վերագույն հաճախությամբ սանդվիչի սահքելու վրա:

Ջերմությունը ազդում է սանդվիչի հեղուկության վրա սահքի ժամանակ: Նախատեսված կառավարումը անհրաժեշտ է սանդվիչի ձևի և մատյան պահպանման համար՝ սահքի գործողության ընթացքում դիֆորմացիաների պահում չառանց:

Ինչպես են կատարվում սովորական պահումները վերագույն հաճախությամբ սանդվիչի սահքող մաքինաների համար:

Սովորական պահումների գործողությունները ներառում են անընդհատ խորհրդային կարագում, տատանումների համակարգի ստորագրումներ և արդյունավետության մետրիկների հետ համատեղելու համար՝ ապահովելու համար մաքինայի օպտիմալ արդյունավետությունը և երկարաժամկետում պահպանելու համար:

Ինչպես լուծել սահքի կցած խնդիրները սանդվիչի տուգանքի ընթացքում:

Սայրի կպչունությունը հաճախ կարելի է լուծել համապատասխան քսանյութերի օգտագործմամբ և աշխատանքային արագությունը կարգավորելով, ինչպես նաև պարբերաբար սպասարկման և կարգաբերման ստուգումներ ապահովելով։

Բովանդակության աղյուսակ

- Ultrasonic Շոկոլադային Սահմանման Հիմնական Սկզբունքների Կարგավորում

- Վերջին 5 սխալ սանդվիչ սահքի ultrasonic տեխնոլոգիայի մեջ՝ որոնց հեռացումը պետք է խուսափել

- Համարժեք մեքենային սահմանափակումը քաղցալի արտադրության համար

- Պահպանագրական Տարբերակներ

- Ելակետների հանդիսացող խնդիրների լուծում

-

Հարցերի և պատասխանների մասին .ultrasonic ստիպում կանդի:

- Ինչ է ultrasonic տատանումը կանդի ստիպման ժամանակ։

- Դիրքի դիրքը ինչու է կարևոր կանդի ստիպման մաքինաներում։

- Ինչպես ազդում է ջերմությունը վերագույն հաճախությամբ սանդվիչի սահքելու վրա:

- Ինչպես են կատարվում սովորական պահումները վերագույն հաճախությամբ սանդվիչի սահքող մաքինաների համար:

- Ինչպես լուծել սահքի կցած խնդիրները սանդվիչի տուգանքի ընթացքում: