The precision of cake cutting operations in commercial bakeries and food processing facilities directly impacts product quality, waste reduction, and overall profitability. Traditional mechanical cutting methods often result in uneven slices, product deformation, and significant material loss, particularly when dealing with delicate frozen desserts or multi-layered confections. Modern ultrasonic cake cutting machine technology revolutionizes this process by utilizing high-frequency vibrations to achieve clean, precise cuts without the drawbacks of conventional blade systems.

Food manufacturers worldwide are increasingly adopting ultrasonic cutting technology to address the growing demand for consistent portion control and enhanced presentation quality. This advanced cutting method eliminates the friction and pressure associated with traditional knives, resulting in superior edge quality and minimal product displacement. The integration of trimming functions further enhances operational efficiency by combining multiple cutting operations into a single automated process.

Advanced Ultrasonic Technology Fundamentals

Vibration Mechanics and Cutting Principles

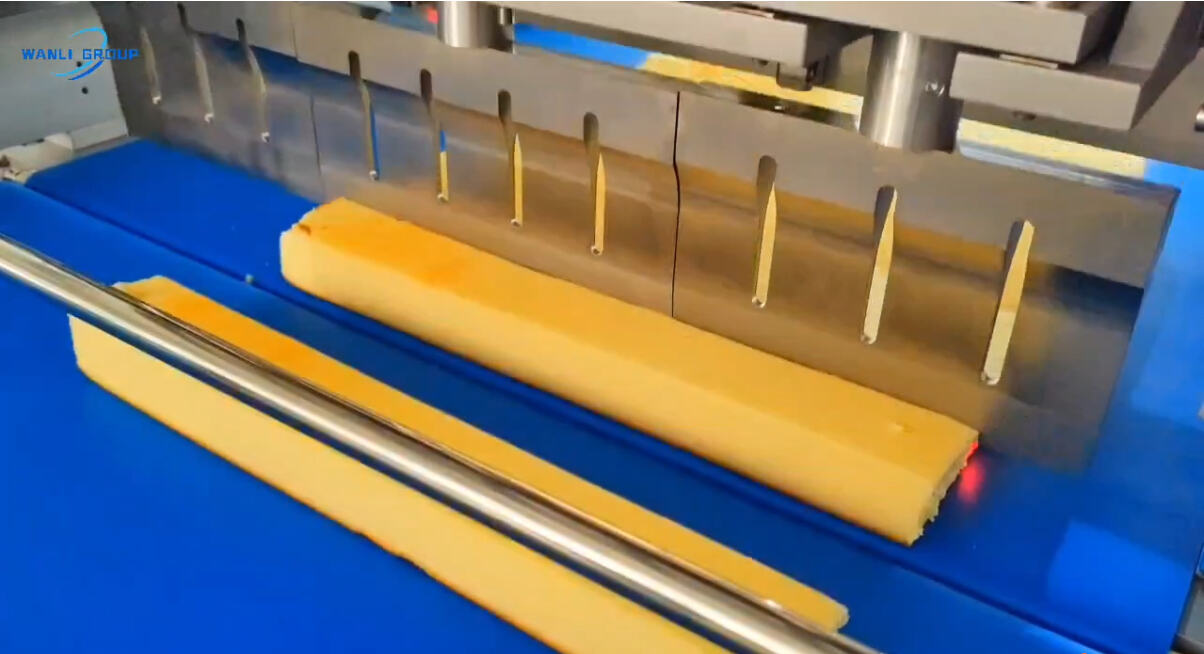

Ultrasonic cutting systems operate on the principle of high-frequency mechanical vibrations, typically ranging from 20 to 40 kilohertz. These vibrations are generated by piezoelectric transducers that convert electrical energy into mechanical motion. The ultrasonic blade oscillates at microscopic amplitudes, creating a cutting action that effectively separates materials without applying significant downward pressure. This mechanism proves particularly effective for temperature-sensitive products like frozen cakes and ice cream, where traditional cutting methods often cause cracking or melting.

The acoustic energy transmitted through the cutting blade creates a temporary reduction in the material's resistance to separation. This phenomenon allows the ultrasonic cake cutting machine to process even the most challenging textures, including hard chocolate coatings, brittle cookie layers, and soft cream fillings, all within a single cutting operation. The consistent vibration pattern ensures uniform cut quality across the entire product surface, eliminating the variations commonly seen with conventional cutting methods.

Temperature Control and Material Preservation

One of the most significant advantages of ultrasonic cutting technology lies in its ability to maintain product temperature integrity throughout the cutting process. Traditional blade cutting generates heat through friction, which can cause unwanted melting or softening of frozen desserts. Ultrasonic systems minimize heat generation while maintaining cutting efficiency, preserving the structural integrity of temperature-sensitive products.

The reduced thermal impact extends beyond frozen products to include chocolate-coated items and cream-filled pastries. Chocolate maintains its temper and glossy finish, while cream fillings retain their shape and consistency. This temperature preservation capability translates directly into improved product appearance and extended shelf life, critical factors in commercial food production environments.

Precision Engineering and Trimming Capabilities

Multi-Directional Cutting Systems

Modern ultrasonic cutting machines incorporate sophisticated multi-axis movement systems that enable precise trimming operations alongside primary cutting functions. These systems can perform complex cutting patterns, including angled cuts, curved profiles, and decorative edge treatments. The programmable nature of these machines allows operators to create custom cutting sequences tailored to specific product requirements.

The trimming function operates with exceptional accuracy, removing excess material while maintaining consistent product dimensions. This capability proves invaluable in high-volume production environments where standardization is crucial for packaging efficiency and portion control. The ability to perform multiple cutting operations in a single pass significantly reduces processing time and labor costs while improving overall product consistency.

Automated Measurement and Quality Control

Integration of advanced sensor technology enables real-time monitoring of cutting accuracy and product dimensions. Laser measurement systems and vision-based quality control ensure that each cut meets predetermined specifications. This automated approach to quality assurance reduces the likelihood of human error and maintains consistent output quality throughout extended production runs.

The feedback control systems continuously adjust cutting parameters based on material characteristics and environmental conditions. This adaptive capability ensures optimal cutting performance regardless of product variations or ambient temperature changes. Operators can monitor cutting statistics and quality metrics through integrated display systems, enabling proactive adjustments to maintain peak performance.

Industrial Applications and Production Benefits

Bakery and Confectionery Operations

Commercial bakeries utilizing ultrasonic cake cutting machine technology report significant improvements in production efficiency and waste reduction. The precision cutting capability enables consistent portion sizes, critical for cost control and customer satisfaction. Delicate products like layered cakes, cream-filled pastries, and decorated desserts maintain their structural integrity throughout the cutting process.

The clean cutting action eliminates the need for frequent blade cleaning and maintenance associated with traditional cutting methods. Cream and frosting residue that typically accumulates on conventional blades is virtually eliminated with ultrasonic technology. This reduction in cleaning requirements translates to increased uptime and improved sanitation standards in food production environments.

Ice Cream and Frozen Dessert Manufacturing

Frozen dessert manufacturers face unique challenges when cutting products that combine multiple textures and temperature-sensitive components. Ice cream cakes containing cookie crumbs, chocolate chips, and various frozen layers require cutting methods that preserve product integrity without causing structural damage. Ultrasonic cutting technology addresses these challenges by providing clean separation without the thermal effects of traditional methods.

The ability to cut frozen products directly from storage temperature eliminates the need for partial thawing, which can compromise product quality and extend processing times. This capability enables manufacturers to maintain optimal product texture and appearance while achieving precise portion control. The reduction in processing steps also minimizes handling requirements and reduces the risk of contamination.

Economic Impact and Operational Efficiency

Waste Reduction and Cost Optimization

Implementation of ultrasonic cutting technology typically results in waste reduction of 15-25% compared to conventional cutting methods. The precision cutting capability minimizes material loss from irregular cuts, cracked surfaces, and trimming waste. This reduction in waste directly impacts raw material costs and improves overall production profitability.

Labor cost savings represent another significant economic benefit of automated ultrasonic cutting systems. The reduction in manual handling requirements and simplified operation procedures enable manufacturers to optimize staffing levels while maintaining or increasing production output. The consistent quality output also reduces the need for manual sorting and quality inspection, further reducing labor costs.

Maintenance and Reliability Considerations

Ultrasonic cutting systems generally require less maintenance than traditional mechanical cutting equipment due to the absence of sharp blades and complex mechanical linkages. The solid-state nature of ultrasonic transducers provides exceptional reliability and longevity when properly maintained. Regular maintenance consists primarily of cleaning procedures and periodic calibration checks.

The modular design of modern ultrasonic cutting systems facilitates rapid component replacement and service procedures. Critical components are designed for field replacement without requiring specialized tools or extensive downtime. This serviceability design approach minimizes the impact of maintenance activities on production schedules and reduces overall equipment lifecycle costs.

FAQ

What types of products can be processed with ultrasonic cake cutting machines

Ultrasonic cake cutting machines can process a wide variety of baked goods and frozen desserts, including layered cakes, ice cream cakes, cheesecakes, brownies, bars, and multi-textured confections. The technology is particularly effective for products containing multiple components like nuts, chocolate chips, fruit pieces, or cream fillings that would typically cause issues with conventional cutting methods.

How does ultrasonic cutting compare to traditional blade cutting in terms of hygiene

Ultrasonic cutting systems offer superior hygiene benefits compared to traditional blade cutting. The vibrating blade action prevents product adhesion and buildup, reducing bacterial growth potential and eliminating the need for frequent blade cleaning during production runs. The smooth, non-stick cutting surface maintains sanitary conditions throughout extended operating periods.

What maintenance requirements are associated with ultrasonic cutting equipment

Maintenance requirements for ultrasonic cutting equipment are minimal compared to conventional systems. Regular cleaning of the cutting surface, periodic calibration of the ultrasonic generator, and inspection of electrical connections comprise the primary maintenance activities. Most systems include self-diagnostic capabilities that alert operators to potential issues before they impact production.

Can ultrasonic cutting machines handle varying product sizes and shapes

Modern ultrasonic cutting machines feature programmable control systems that accommodate various product sizes and cutting patterns. Operators can easily adjust cutting dimensions, create custom cutting sequences, and store multiple product recipes for quick changeover between different items. The flexible programming capability enables efficient processing of diverse product lines without requiring manual adjustments or tooling changes.

Table of Contents

- Advanced Ultrasonic Technology Fundamentals

- Precision Engineering and Trimming Capabilities

- Industrial Applications and Production Benefits

- Economic Impact and Operational Efficiency

-

FAQ

- What types of products can be processed with ultrasonic cake cutting machines

- How does ultrasonic cutting compare to traditional blade cutting in terms of hygiene

- What maintenance requirements are associated with ultrasonic cutting equipment

- Can ultrasonic cutting machines handle varying product sizes and shapes