Modern food processing facilities are constantly seeking innovative solutions to enhance production efficiency while maintaining product quality and consistency. Traditional cutting methods often struggle with challenging textures, create excessive waste, and require frequent blade maintenance. The emergence of advanced ultrasonic food cutters has revolutionized how manufacturers approach food processing, offering precision cutting capabilities that significantly improve operational efficiency across various production lines.

The food processing industry faces mounting pressure to deliver consistent products while minimizing waste and reducing production costs. Conventional mechanical cutting systems often result in product deformation, uneven cuts, and contamination issues that impact both quality and profitability. These challenges have driven manufacturers to explore cutting-edge technologies that can address these limitations while streamlining their operations.

Advanced Technology Behind Modern Ultrasonic Cutting Systems

High-Frequency Vibration Mechanics

Ultrasonic food cutters operate through sophisticated high-frequency vibration technology that generates rapid oscillations at frequencies typically ranging from 20,000 to 40,000 Hz. This ultrasonic energy creates microscopic movements in the cutting blade that effectively reduce friction between the cutting surface and the food product. The vibrating blade moves through materials with minimal resistance, creating clean, precise cuts without the crushing or tearing effects commonly associated with traditional cutting methods.

The ultrasonic frequency can be precisely calibrated to match specific food textures and densities, ensuring optimal cutting performance across diverse product categories. This adaptability makes these systems particularly valuable for facilities processing multiple food types, as operators can adjust parameters to achieve consistent results regardless of the material being processed.

Blade Design and Material Engineering

Contemporary ultrasonic cutting systems feature specially engineered blades constructed from advanced materials that maintain sharpness longer and resist wear from continuous high-frequency operation. These blades are designed with specific geometries that maximize the transmission of ultrasonic energy while providing optimal cutting performance for various food applications.

The blade configuration often includes multiple cutting edges or specialized surface treatments that enhance cutting efficiency and reduce product adhesion. This engineering approach ensures that sticky or delicate foods maintain their structural integrity during processing while achieving the precise dimensions required for packaging and presentation.

Operational Efficiency Improvements in Food Processing

Reduced Processing Time and Increased Throughput

Implementation of ultrasonic food cutters in processing lines typically results in substantial reductions in cutting time compared to conventional methods. The smooth cutting action requires less force and creates minimal resistance, allowing for faster processing speeds without compromising cut quality. Many facilities report throughput increases of 30-50% when transitioning from traditional cutting systems to ultrasonic alternatives.

The consistent cutting speed enabled by ultrasonic technology also allows for better integration with automated packaging systems and downstream processing equipment. This synchronization reduces bottlenecks in production lines and creates more predictable workflow patterns that facility managers can optimize for maximum efficiency.

Minimized Product Waste and Material Loss

Traditional cutting methods often generate significant waste through product deformation, crumb generation, and irregular cuts that fail to meet packaging specifications. Ultrasonic food cutters dramatically reduce waste by creating clean, precise cuts that maintain product integrity and minimize material loss during processing.

The reduced waste not only improves material utilization rates but also decreases cleanup requirements and reduces disposal costs. Facilities processing high-value ingredients particularly benefit from this efficiency improvement, as even small reductions in waste can translate to significant cost savings over time.

Quality Enhancement and Product Consistency

Superior Cut Quality and Appearance

Ultrasonic cutting technology produces remarkably clean cuts with smooth surfaces that enhance product appearance and marketability. The high-frequency vibration prevents the tearing and crushing effects that often occur with conventional blades, resulting in professional-looking products that meet strict quality standards for retail and food service applications.

The consistent cut quality achieved through ultrasonic technology also improves packaging efficiency and product presentation. Uniform dimensions and clean edges allow for better stacking, reduced air gaps in packaging, and improved visual appeal that can positively impact consumer perception and sales performance.

Maintained Product Integrity and Texture

One of the most significant advantages of ultrasonic food cutters is their ability to preserve the original texture and structural characteristics of processed foods. Delicate items such as layered cakes, filled pastries, and soft cheeses maintain their internal structure and visual appeal when cut with ultrasonic technology, whereas traditional methods often cause compression or deformation.

This preservation of product integrity is particularly important for premium food products where appearance and texture directly impact consumer satisfaction and brand reputation. Manufacturers can maintain higher quality standards while achieving the production volumes necessary for commercial success.

Maintenance and Operational Cost Benefits

Reduced Blade Replacement and Sharpening Requirements

The unique cutting mechanism of ultrasonic systems significantly extends blade life compared to traditional cutting equipment. The vibrating action reduces blade wear by minimizing direct contact pressure with food products, resulting in longer intervals between blade replacements and reduced maintenance costs.

Additionally, the self-cleaning effect of ultrasonic vibration helps prevent product buildup on blade surfaces, reducing the frequency of cleaning cycles and minimizing downtime for maintenance activities. This characteristic is especially valuable in facilities processing sticky or high-fat content foods that typically cause rapid blade fouling with conventional equipment.

Lower Energy Consumption and Operating Costs

Modern ultrasonic food cutters are designed for energy efficiency, often consuming less power than comparable traditional cutting systems while delivering superior performance. The reduced cutting force requirements and optimized motor systems contribute to lower electricity consumption, which can result in meaningful cost savings for high-volume processing operations.

The combination of reduced maintenance requirements, extended equipment life, and lower energy consumption creates a compelling total cost of ownership profile that justifies the initial investment in ultrasonic cutting technology for most commercial food processing applications.

Applications Across Food Processing Industries

Bakery and Confectionery Operations

Bakery facilities have found ultrasonic food cutters particularly effective for slicing delicate products such as layer cakes, cream-filled pastries, and artisanal breads. The precise cutting action prevents filling displacement and maintains the visual appeal that is crucial for bakery products. Many commercial bakeries report improved portion control and reduced waste when processing high-value items with ultrasonic systems.

Confectionery manufacturers benefit from the clean cuts achieved when processing chocolate-coated items, nougats, and other sticky confections that traditionally challenge conventional cutting equipment. The non-stick properties of ultrasonic cutting help maintain production flow and reduce cleaning requirements in these demanding applications.

Cheese and Dairy Product Processing

Cheese processing facilities utilize ultrasonic cutting technology to achieve consistent portioning of both hard and soft cheese varieties. The technology excels at cutting through cheese without causing cracking in hard varieties or deformation in soft cheeses, maintaining product quality while improving processing efficiency.

Dairy processors also employ ultrasonic food cutters for specialty products such as frozen desserts and layered dairy products where maintaining structural integrity during cutting is essential for product quality and consumer appeal.

Implementation Considerations for Processing Facilities

Integration with Existing Production Lines

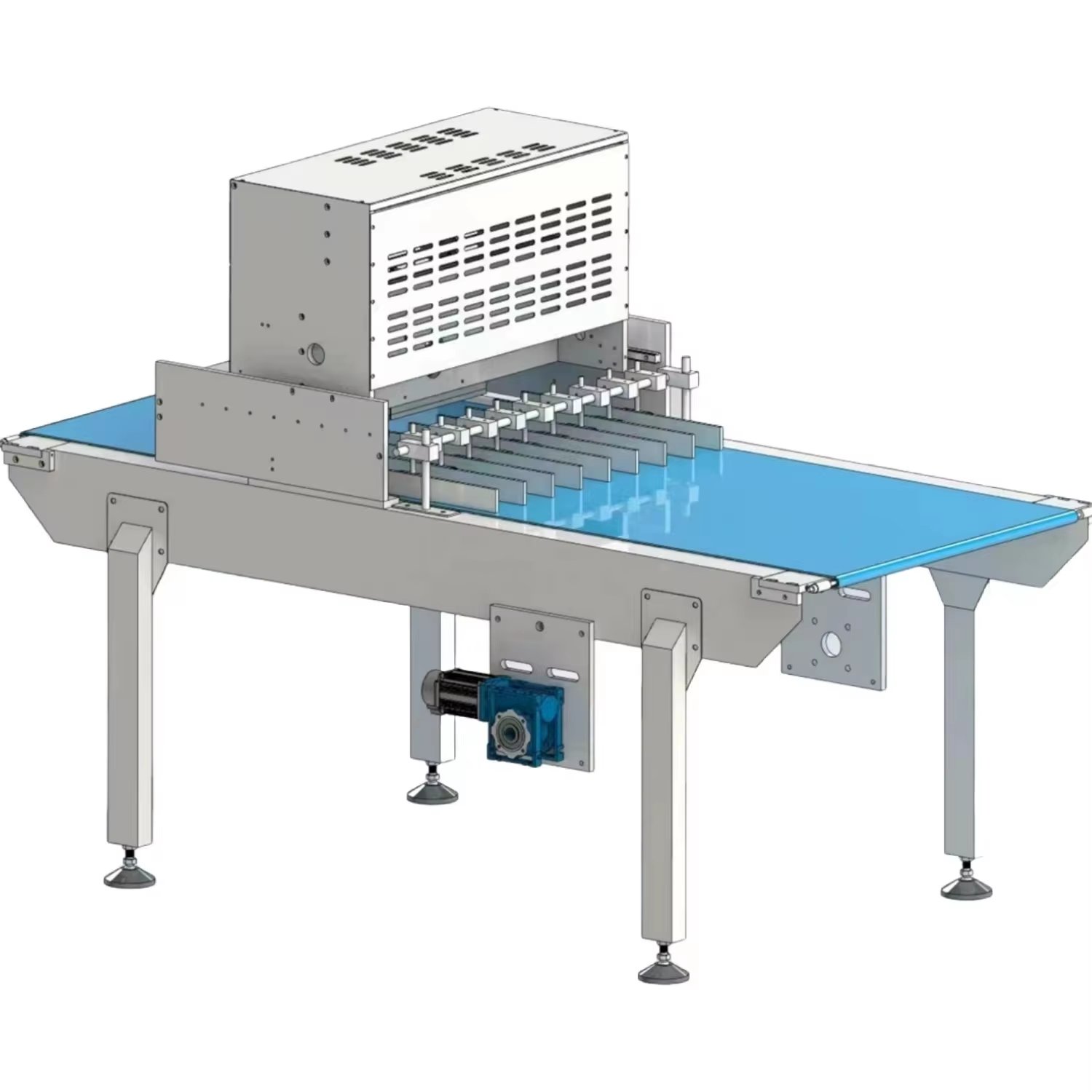

Successfully implementing ultrasonic cutting technology requires careful consideration of existing production line configurations and workflow patterns. Most modern ultrasonic systems are designed for seamless integration with conveyor systems, packaging equipment, and quality control stations, but facilities must evaluate their specific requirements to ensure optimal performance.

The flexibility of ultrasonic food cutters allows for customization to match specific production requirements, including adjustable cutting speeds, programmable cut patterns, and automated feeding systems that can accommodate varying product sizes and shapes without manual intervention.

Staff Training and Safety Protocols

While ultrasonic cutting systems are generally safer than traditional blade-based equipment, proper staff training is essential for optimal operation and safety. Operators must understand the technology principles, maintenance requirements, and safety protocols specific to ultrasonic equipment to ensure safe and efficient operation.

The reduced noise levels and elimination of sharp blade hazards associated with ultrasonic food cutters contribute to improved working conditions and reduced safety risks compared to conventional cutting systems, making them attractive options for facilities prioritizing worker safety and comfort.

FAQ

How do ultrasonic food cutters compare to traditional blade systems in terms of cutting speed

Ultrasonic food cutters typically operate 30-50% faster than traditional blade systems due to reduced friction and cutting resistance. The high-frequency vibration allows the blade to move through food products with minimal force, enabling higher processing speeds while maintaining superior cut quality and reducing product waste.

What types of food products benefit most from ultrasonic cutting technology

Delicate, sticky, or multi-layered food products benefit most from ultrasonic cutting, including layer cakes, filled pastries, soft cheeses, frozen desserts, and chocolate-coated confections. These products often suffer deformation or damage with traditional cutting methods but maintain their integrity and appearance when processed with ultrasonic technology.

Are ultrasonic food cutters more expensive to maintain than conventional cutting equipment

Ultrasonic food cutters generally have lower maintenance costs due to extended blade life, reduced cleaning requirements, and fewer mechanical wear components. While initial investment may be higher, the reduced maintenance frequency and lower operational costs typically result in better total cost of ownership compared to traditional cutting systems.

Can ultrasonic cutting systems handle high-volume commercial food processing operations

Yes, modern ultrasonic food cutters are specifically designed for high-volume commercial applications and can process thousands of units per hour depending on product size and cutting requirements. Many systems offer automated feeding, programmable cutting patterns, and integration capabilities that support continuous production in demanding commercial environments.

Table of Contents

- Advanced Technology Behind Modern Ultrasonic Cutting Systems

- Operational Efficiency Improvements in Food Processing

- Quality Enhancement and Product Consistency

- Maintenance and Operational Cost Benefits

- Applications Across Food Processing Industries

- Implementation Considerations for Processing Facilities

-

FAQ

- How do ultrasonic food cutters compare to traditional blade systems in terms of cutting speed

- What types of food products benefit most from ultrasonic cutting technology

- Are ultrasonic food cutters more expensive to maintain than conventional cutting equipment

- Can ultrasonic cutting systems handle high-volume commercial food processing operations