ข้อมูลติดต่อ

ยูนิต 1011, ปิงหนิง อินดัสเตรียล, เขตหลงไฮ, เมืองจางโจว, มณฑลฝูเจี้ยน

นิวยอร์ก

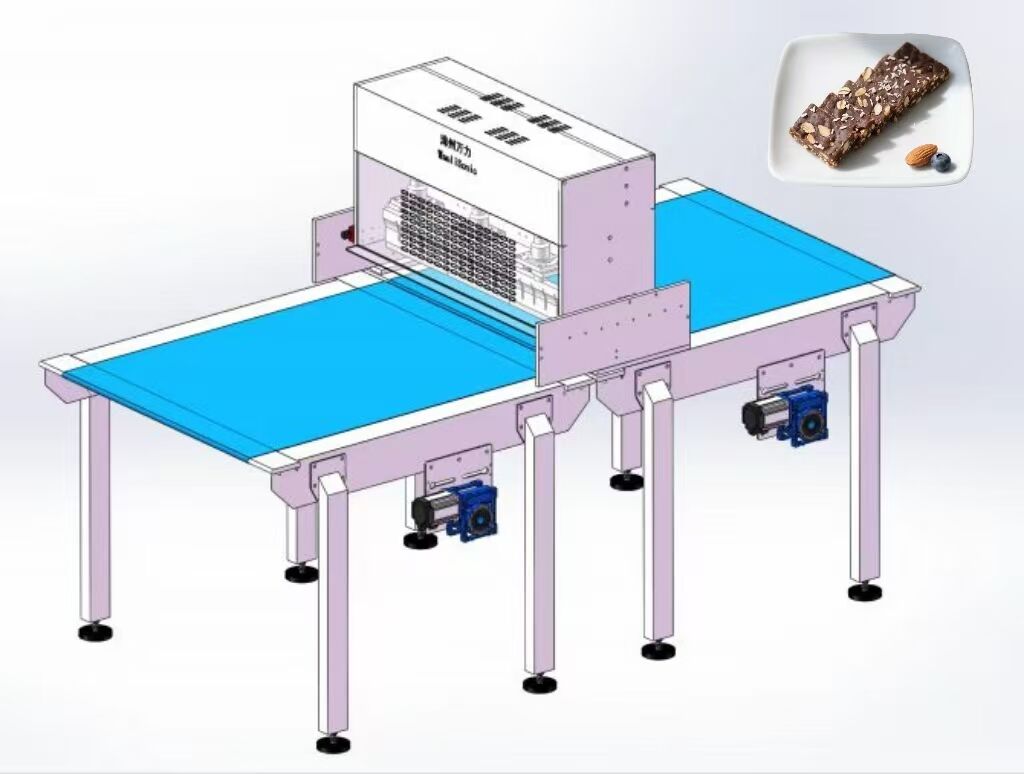

สำหรับผู้ผลิตขนมหวานทั่วโลก ขั้นตอนการตัดผลิตภัณฑ์เช่นนูการ์ต ซึ่งมีพื้นผิวเหนียวและยืดหยุ่น มานานแล้วที่ถือเป็นจุดคับขันที่ส่งผลต่อทั้งประสิทธิภาพการผลิตและคุณภาพของผลิตภัณฑ์ เทคนิคการตัดแบบดั้งเดิมมักก่อให้เกิดปัญหาเนื้อติด มีขอบขรุขระ และขนาดไม่สม่ำเสมอ ส่งผลให้วัสดุสูญเสียไปและภาพลักษณ์ของผลิตภัณฑ์ด้อยลง จางโจว หว่านหลี่ แนะนำ เครื่องตัดทอฟฟี่ด้วยคลื่นอัลตราโซนิก Wanli ที่ได้รับการออกแบบมาโดยเฉพาะเพื่อแก้ไขปัญหาเหล่านี้ โดยใช้เทคโนโลยีขั้นสูง เทคโนโลยี Wanlisonic , มันได้กำหนดมาตรฐานการตัดใหม่สำหรับผลิตภัณฑ์ที่เหนียว ช่วยให้ธุรกิจสามารถผลิตได้อย่างมีประสิทธิภาพและแม่นยำ

การตัดด้วยคลื่นอัลตราโซนิก: เทคโนโลยีที่เปลี่ยนเกม

เพื่อเข้าใจถึงความโดดเด่นของ เครื่องตัดทอฟฟี่ด้วยคลื่นอัลตราโซนิก Wanli , ผู้ใช้จำเป็นต้องเข้าใจเทคโนโลยีหลักที่ขับเคลื่อนมันก่อน นั่นคือ การตัดด้วยคลื่นเสียงอัลตราโซนิก เทคโนโลยีนี้ไม่ได้อาศัยแรงกดกลไกหรือความคมของใบมีดแบบดั้งเดิม แต่จะใช้ เครื่องกำเนิดอัลตราโซนิก แปลงพลังงานไฟฟ้าเป็นการสั่นสะเทือนเชิงกลความถี่สูงนับหมื่นครั้งต่อวินาที การสั่นสะเทือนนี้จะถูกส่งผ่านไปยัง "ใบมีดอัลตราโซนิก" ทำให้เกิดการสั่นในระดับจุลภาค

เมื่อใบมีดที่สั่นสะเทือนอย่างรวดเร็วนี้สัมผัสกับเนื้อทอฟฟี่ มันจะใช้พลังงานการสั่นสะเทือนในการแยกพันธะระหว่างโมเลกุลของลูกกวาดออกทันทีและอย่างอ่อนโยน แทนที่จะเป็นการ "กดผ่าน" หรือ "ฉีกขาด" วัสดุ ซึ่งให้ข้อได้เปรียบที่ปฏิวัติวงการ: การตัดที่ปราศจากแรงกด ซึ่งป้องกันไม่ให้ลูกกวาดนุ่มถูกบีบและเสียรูปอย่างสิ้นเชิง พื้นผิวการตัดที่เรียบเนียนสมบูรณ์แบบเหมือนกระจก โดยไม่มีเศษหลุดร่วง และการกำจัดปัญหาใบมีดติดลูกกวาดอย่างสิ้นเชิง เนื่องจากการสั่นสะเทือนความถี่สูงจะสร้างช่องว่างในระดับไมโครระหว่างใบมีดกับลูกกวาดที่มีความเหนียวสูง ทำให้เกิดการแยกตัวอัตโนมัติหลังจากการตัดแต่ละครั้ง เพื่อให้มั่นใจถึงการดำเนินงานอย่างต่อเนื่อง นี่คือพื้นฐานทางเทคโนโลยีที่ทำให้ เครื่องจักรและอุปกรณ์ Wanli , ภายใต้ ว่านลี่ กรุ๊ป , สามารถรับประกันความสม่ำเสมอของผลิตภัณฑ์และคุณภาพระดับพรีเมียม

เครื่องตัดทอฟฟี่อัลตราโซนิก Wanli: เกิดมาเพื่อลูกกวาดเหนียว

ต่อยอดจาก เทคโนโลยีอัลตราโซนิกหลักนี้ , ทีมวิศวกรที่ ว่านลี่ กรุ๊ป ได้พัฒนาโซลูชันการตัดแนวตั้งนี้อย่างพิถีพิถัน โดยออกแบบให้เหมาะสมกับคุณสมบัติทางกายภาพของนูการ์ต

1. การตัดด้วยความแม่นยำ ปรับนิยามใหม่ให้กับรูปลักษณ์ของผลิตภัณฑ์

เป้าหมายหลักของ เครื่องตัดทอฟฟี่ด้วยคลื่นอัลตราโซนิก Wanli คือการแก้ไขปัญหาสองประการ ได้แก่ ปัญหา "ติด" และ "เสียรูป" โดย ใบมีดอัลตราโซนิก ซึ่งทำงานที่ความถี่ 20kHz หรือสูงกว่า สร้างความร้อนและแรงดึงทางกลที่ต่ำมากในระหว่างการตัด ทำให้มั่นใจได้ว่าชิ้นนูการ์ตทุกชิ้นจะคงรูปร่างที่ตั้งใจไว้อย่างสม่ำเสมอ พร้อมขอบที่เรียบและสะอาด และหน้าตัดที่ชัดเจนน่าดึงดูด ความใส่ใจอย่างพิถีพิถันต่อรูปลักษณ์ของผลิตภัณฑ์นี้ ส่งผลโดยตรงต่อการเพิ่มความน่าสนใจบนชั้นวางสินค้า และเพิ่มมูลค่าแบรนด์

2. มีประสิทธิภาพสูงและเปี่ยมด้วยปัญญาประดิษฐ์ ช่วยยกระดับประสิทธิภาพของสายการผลิต

เครื่องนี้สะท้อนถึงการผสานรวมระหว่างความอัจฉริยะและความมีประสิทธิภาพสูง ในฐานะอุปกรณ์แบบเรียงต่อ (in-line) สามารถรวมเข้ากับสายการผลิตขนมได้อย่างไร้รอยต่อ ทำให้กระบวนการทำงานอัตโนมัติอย่างต่อเนื่องตั้งแต่ขั้นตอนการขึ้นรูป การตัด ไปจนถึงการบรรจุหีบห่อ โดยมีหน้าจอสัมผัสสีที่ใช้งานง่าย ผู้ปฏิบัติงานสามารถตั้งค่าและจัดเก็บพารามิเตอร์ต่างๆ เช่น ความหนาของการตัด และความเร็ว สำหรับผลิตภัณฑ์แต่ละชนิด พร้อมเปลี่ยนโหมดการผลิตด้วยการแตะเพียงครั้งเดียว

ทำงานที่ความถี่คงที่ในช่วง 30-40 ครั้งต่อนาที ช่วยเพิ่มผลผลิตอย่างมาก ลดแรงงาน และให้ความสม่ำเสมอของปริมาณต่อหน่วยที่เหนือระดับ ควบคุมอย่างแม่นยำไม่เพียงแต่ช่วยลดของเสียจากวัสดุ แต่ยังสร้างประหยัดต้นทุนและความก้าวหน้าด้านประสิทธิภาพให้กับธุรกิจได้อย่างมีนัยสำคัญ

3. แข็งแรง ทนทาน และบำรุงรักษาง่าย

ยึดมั่นใน พันธสัญญาอันแน่วแน่ของกลุ่มบริษัท Wanli ต่อคุณภาพที่เชื่อถือได้ เครื่องตัดทอฟฟี่ด้วยคลื่นอัลตราโซนิก Wanli ใช้โครงสร้างหลักจากสแตนเลสเหล็กที่แข็งแรง และชิ้นส่วนที่ปลอดภัยสำหรับอาหาร พร้อมด้วย ระบบใบมีดอัลตราโซนิก ได้รับการประมวลผลด้วยกระบวนการพิเศษเพื่อยืดอายุการใช้งานและเพิ่มความต้านทานต่อการสึกหรอ โดยเฉพาะอย่างยิ่งการออกแบบที่ให้ความสำคัญกับประสบการณ์การบำรุงรักษาในชีวิตประจำวันของผู้ใช้งาน คุณสมบัติการตัดแบบไม่ติดนี้ช่วยลดความจำเป็นในการทำความสะอาดอย่างมาก เมื่อรวมกับการออกแบบแบบโมดูลาร์ งานต่างๆ เช่น การเปลี่ยนหัวใบมีดและการบำรุงรักษารวมๆ จึงกลายเป็นเรื่องง่ายและรวดเร็วเป็นพิเศษ ช่วยลดเวลาหยุดทำงานที่ไม่ได้วางแผนไว้

เหตุใดจึงควรเลือกกลุ่มบริษัท Wanli

การเลือก เครื่องตัดทอฟฟี่ด้วยคลื่นอัลตราโซนิก Wanli หมายถึงการเลือกพันธมิตรทางเทคโนโลยีที่เชื่อถือได้ กลุ่มบริษัท Wanli มีความชำนาญทางเทคนิคลึกซึ้งและมีประสบการณ์อุตสาหกรรมที่กว้างขวางในด้าน การประยุกต์ใช้อัลตราโซนิก - ไม่ มัน แบรนด์เทคโนโลยี Wanlsonic ได้กลายเป็นสัญลักษณ์ของความแม่นยำ ความน่าเชื่อถือ และนวัตกรรม ฐานการผลิตที่ จางโจว หว่านหลี่ ผสานการวิจัยและพัฒนา การผลิต และการควบคุมคุณภาพเข้าด้วยกัน เพื่อให้มั่นใจว่าเครื่องจักรทุกเครื่องจะเป็นไปตามมาตรฐานสากล

เราเข้าใจดีว่าทุกธุรกิจมีความต้องการที่แตกต่างกัน ดังนั้น เราไม่เพียงแต่จัดหาอุปกรณ์ประสิทธิภาพสูงที่ได้มาตรฐาน แต่ยังทุ่มเทให้บริการสนับสนุนอย่างครบวงจร—ตั้งแต่การประเมินสายการผลิตและโซลูชันแบบเฉพาะเจาะจง ไปจนถึงการติดตั้ง การเดินเครื่อง และการฝึกอบรมเชิงเทคนิค

สรุป

ในอุตสาหกรรมขนมหวานที่มีการแข่งขันสูงขึ้นเรื่อยๆ ในปัจจุบัน การใส่ใจอย่างพิถีพิถันต่อประสิทธิภาพการผลิต คุณภาพผลิตภัณฑ์ และการควบคุมต้นทุน คือกุญแจสำคัญของความสำเร็จ ด้วยเทคโนโลยีที่ทันสมัย การออกแบบอัจฉริยะ และสมรรถนะที่เชื่อถือได้ เครื่องตัดทอฟฟี่ด้วยคลื่นอัลตราโซนิก Wanli กำลังกลายเป็นเครื่องมือที่ทรงพลังสำหรับผู้ผลิตขนมหวานทั่วโลกในการปรับปรุงสายการผลิตและสร้างขีดความสามารถหลัก มาทำงานร่วมกันเพื่อใช้เทคโนโลยีเปิดเส้นทางสู่อนาคตที่หวานมากยิ่งขึ้นและมีประสิทธิภาพสูงขึ้น

คำถามที่พบบ่อย

คำถามที่ 1: นอกจากทอฟฟี่แล้ว เครื่องนี้สามารถตัดขนมชนิดอื่นได้อีกไหม

คำตอบที่ 1: ได้อย่างแน่นอน เครื่องตัดทอฟฟี่ด้วยคลื่นอัลตราโซนิก Wanli ออกแบบมาสำหรับลูกกวาดที่ยึดติดได้ดีและเปลี่ยนรูปร่างได้ง่าย โดยสามารถใช้กับผลิตภัณฑ์ที่มีคุณสมบัติทางกายภาพคล้ายกัน เช่น ทอฟฟี่ และลูกกวาดนมเนื้อนิ่มบางชนิด โดยต้องปรับค่าพารามิเตอร์เพียงเล็กน้อย

คำถามที่ 2: การตัดด้วยคลื่นเสียงอัลตราโซนิก สามารถป้องกันการติดของใบมีดได้จริงทั้งหมดหรือไม่? ต้องทำความสะอาดบ่อยแค่ไหน?

คำตอบที่ 2: ใช่ หลักการทำงานของ การสั่นสะเทือนอัลตราโซนิกความถี่สูง ช่วยป้องกันการยึดติดของวัสดุได้โดยตรง ซึ่งเป็นข้อได้เปรียบทางเทคนิคหลัก เมื่อเทียบกับอุปกรณ์แบบดั้งเดิม ความถี่ในการทำความสะอาดลดลงอย่างมาก ในการผลิตตามปกติอาจต้องการทำความสะอาดผิวเพียงเล็กน้อยเท่านั้น และช่วงเวลาที่ต้องทำความสะอาดลึกก็ยืดออกไปอย่างมาก

คำถามที่ 3: การใช้งานอุปกรณ์ซับซ้อนหรือไม่? ต้องใช้ผู้ปฏิบัติงานเฉพาะหรือไม่?

คำตอบที่ 3: การใช้งานง่ายมาก เรามีการออกแบบอินเทอร์เฟซหน้าจอสัมผัสแบบกราฟิกที่ใช้งานง่าย มีขั้นตอนที่ชัดเจน พนักงานสายการผลิตทั่วไปสามารถเรียนรู้การปฏิบัติงานประจำวันและการตั้งค่าพารามิเตอร์ได้หลังการฝึกอบรมเบื้องต้น

คำถามที่ 4: การใช้พลังงานและค่าใช้จ่ายในการดำเนินงานของเครื่องสูงหรือไม่?

A4: ในทางตรงกันข้าม นี่คือหนึ่งในข้อได้เปรียบที่สำคัญของมัน การตัดด้วยคลื่นเสียงอัลตราโซนิก เป็นกระบวนการที่มีประสิทธิภาพในการใช้พลังงานสูง เนื่องจากพลังงานหลักถูกใช้เพื่อสร้างการสั่นสะเทือนความถี่สูง แทนที่จะใช้แรงกล ทำให้โดยรวมใช้พลังงานน้อยลง เมื่อรวมกับประโยชน์อื่นๆ ที่ช่วยประหยัดแรงงานและลดของเสีย จึงช่วยลดต้นทุนการดำเนินงานในระยะยาวของคุณได้อย่างมีประสิทธิภาพ

Q5: หากสายการผลิตของฉันต้องการการปรับแต่งพิเศษ บริษัทสามารถให้การสนับสนุนได้หรือไม่ ว่านลี่ ให้การสนับสนุนได้หรือไม่

A5: ได้อย่างแน่นอน การให้โซลูชันที่ปรับแต่งได้คือบริการหลักของ Wanli Machinery ทีมวิศวกรของเราสามารถจัดทำแผนการติดตั้งและปรับแต่งอย่างมืออาชีพ ตามรูปแบบการจัดวางสายการผลิต ข้อกำหนดของผลิตภัณฑ์ และเป้าหมายการผลิตที่คุณต้องการ ทำให้มั่นใจได้ว่าอุปกรณ์จะสอดคล้องกับความต้องการการผลิตของคุณอย่างสมบูรณ์แบบ

ข่าวเด่น

ข่าวเด่น2025-12-14

2025-12-13

2025-12-12

2025-12-11

2025-12-10

2025-12-08