Contact Info

Unit 1011, Pingning Industrial, Longhai District, Zhangzhou City, Fujian Province

New York.

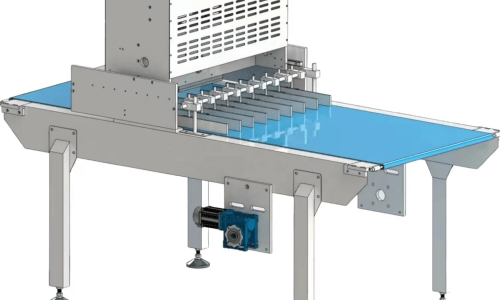

If you’ve ever enjoyed a perfectly shaped gummy bear or a chewy candy that looks identical to the others in the pack, chances are ultrasonic cutting technology was involved. The Wanli ultrasonic gummy candy cutting machine is one of the most advanced solutions in the confectionery industry today. It ensures consistency, speed, and precision that traditional cutting methods simply can’t match.

But what exactly is it, and why does it matter so much to candy makers worldwide? Let’s dive in.

|

|

Understanding Ultrasonic Cutting Technology

Ultrasonic cutting uses high-frequency vibrations to slice through food products with minimal resistance. Unlike knives that drag and stick, ultrasonic blades move so fast that they glide effortlessly through sticky, gummy, or soft materials.

Why it’s revolutionary:

Zero sticking to blades.

Smooth, clean edges.

Works with sticky, soft, and delicate products.

What Makes Wanli Different?

Wanli has earned its reputation by combining innovation, durability, and efficiency. Unlike generic machines, Wanli focuses on precision engineering and user-friendly designs that cater specifically to the confectionery industry.

Their ultrasonic cutters are built to handle large-scale candy production without compromising on quality.

Key Features of Wanli Ultrasonic Gummy Candy Cutting Machin|

High precision cutting: Every candy is uniform in shape and size.

Non-stick blades: No more gummy residues stuck to the cutter.

Automation: Supports large-scale, continuous production.

Custom configurations: Adjustable blade sizes and shapes.

Durable build: Designed for heavy-duty industrial use.

How It Works

Candies move along the conveyor.

Ultrasonic blades vibrate at high frequencies.

Blades cut through gummies smoothly, without crushing or distorting them.

Finished pieces are neatly separated and ready for packaging.

The process integrates seamlessly with modern candy production lines, saving time and labor.

Applications in the Confectionery Industry

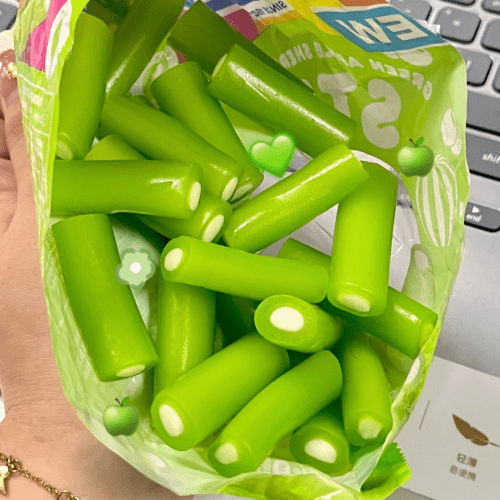

While the machine is primarily used for gummy candy, it’s not limited to just one sweet treat. Manufacturers use it for:

Jelly candies,Marshmallows,Fruit snacks,Chewy bars

Advantages for Manufacturers

Faster production: Handle thousands of gummies per minute.

Better consistency: Identical pieces every time.

Less waste: Clean cuts mean no misshaped rejects.

Improved hygiene: Non-stick blades minimize contamination risks.

Comparing Ultrasonic Cutting vs. Traditional Cutting

Aspect Traditional Cutting Ultrasonic Cutting (Wanli)

Speed Slower Faster, continuous

Blade sticking Common issue Non-stick technology

Product quality Uneven edges Smooth, precise cuts

Maintenance Higher wear/tear Longer blade life

Customization Options

Manufacturers can choose:

Blade sizes for different candy dimensions.

Conveyor speed adjustments.

Full automation or semi-automatic versions.

This flexibility makes Wanli ideal for both large factories and smaller candy makers.

Hygiene and Food Safety Standards

Food safety is a top priority. Wanli machines are

Easy to disassemble for cleaning.

Made of food-grade stainless steel.

Designed to comply with FDA, CE, and other global food standards.

Energy Efficiency and Sustainability

Wanli ultrasonic machines are engineered to reduce energy use while improving productivity. By minimizing waste and maximizing output, they contribute to a more sustainable candy-making process.

Who Uses Wanli Ultrasonic Candy Cutting Machines?

Large confectionery brands producing millions of gummies weekly.

Medium-sized candy companies expanding into automation.

Innovative startups looking for high-quality candy production tools.

ROI and Cost Benefits

Though the initial investment might seem high, companies quickly recover costs through:

Lower waste production.,Faster output,Reduced labor expenses.Many manufacturers report ROI within the first year of adoption.

Customer Testimonials and Case Studies

Across the globe, candy makers praise Wanli for boosting efficiency. A European candy brand, for example, reported a 30% increase in production speed after switching to Wanli ultrasonic machines.

Future of Ultrasonic Cutting in Confectionery

The future is clear: ultrasonic cutting will continue shaping the confectionery industry. With AI-driven production lines, IoT integration, and even smarter machines, Wanli is leading the way toward more efficient, automated candy-making solutions.

The Wanli ultrasonic gummy candy cutting machine is more than just a piece of equipment—it’s a game-changer for the candy industry. By offering precision, speed, hygiene, and efficiency, Wanli has set the benchmark for confectionery automation.

Whether you’re a global candy manufacturer or a local sweet shop aiming to scale up, investing in this technology could be the sweetest decision you’ll ever make.

|

|

Hot News

Hot News2025-12-14

2025-12-13

2025-12-12

2025-12-11

2025-12-10

2025-12-08