การทำงานของเทคโนโลยีการตัดด้วยคลื่นเสียงความถี่สูงสำหรับชิ้นเค้กที่สมบูรณ์แบบ

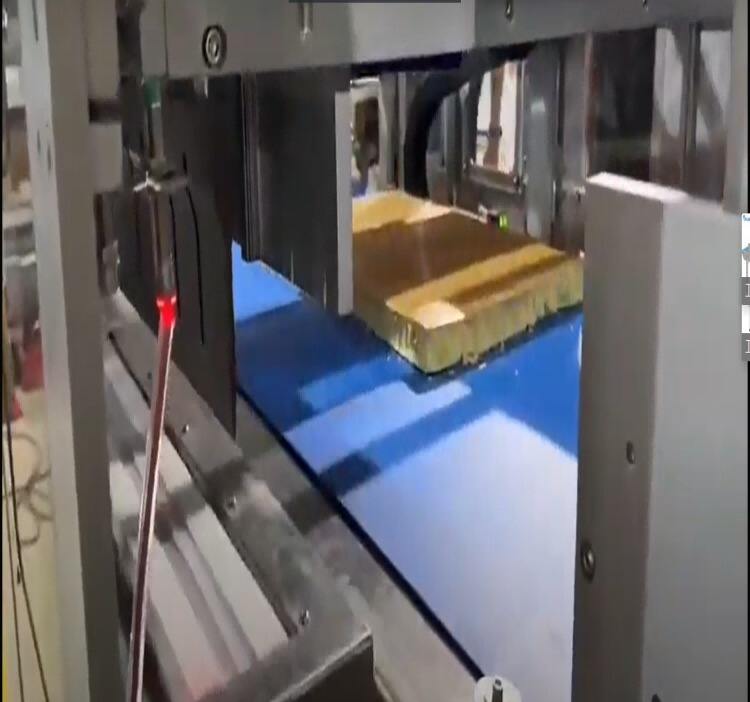

เทคโนโลยีการตัดด้วยคลื่นอัลตราโซนิกเป็นการเปลี่ยนแปลงครั้งใหญ่ในอุตสาหกรรมการตัดเค้ก ช่วยให้มั่นใจได้ว่าทุกแผ่นเค้กจะตัดออกมาสมบูรณ์แบบเสมอ วิธีการนี้ใช้คลื่นเสียงความถี่สูงเพื่อสร้างการสั่นสะเทือนอย่างรวดเร็ว ซึ่งช่วยให้การตัดมีความรวดเร็วและแม่นยำโดยไม่ทำลายโครงสร้างของเค้ก การศึกษาทางวิทยาศาสตร์แสดงให้เห็นว่าคลื่นอัลตราโซนิกสามารถลดแรงยึดเหนี่ยวระหว่างชั้นของเค้กได้อย่างมีประสิทธิภาพ เพิ่มความแม่นยำและความคมชัดของการตัด ทำให้ได้แผ่นเค้กที่สะอาดและสม่ำเสมอ โดยปกติแล้ว ความถี่ที่ใช้ในการตัดเค้กจะอยู่ระหว่าง 20 kHz ถึง 40 kHz ซึ่งมอบสมดุลที่เหมาะสมระหว่างประสิทธิภาพและความคุ้มค่า เพื่อให้ได้ผลลัพธ์ที่สมบูรณ์แบบเสมอ การนำเทคโนโลยีขั้นสูงเช่นนี้มาใช้ จะช่วยให้ร้านเบเกอรี่รักษาความสวยงามและความแข็งแรงของผลงานการทำอาหารไว้ได้

วิทยาศาสตร์เบื้องหลังการสั่นสะเทือนแบบอัลตราโซนิก

หลักการทางวิทยาศาสตร์ของความสั่นสะเทือนอัลตราโซนิกมีรากฐานมาจากฟิสิกส์ โดยใช้คลื่นเสียงความถี่สูงเพื่อสร้างการสั่นสะเทือนอย่างรวดเร็วสำหรับการตัดเค้กให้เนียนเรียบ เมื่อคลื่นเสียงเหล่านี้ถูกส่งไปยังเครื่องมือตัด การสั่นสะเทือนจะช่วยให้ตัดได้อย่างแม่นยำโดยไม่ทำให้เค้กถูกทุบหรือแตกเป็น vụn งานวิจัยแสดงให้เห็นว่าคลื่นอัลตราโซนิกช่วยลดแรงยึดเกาะระหว่างชั้นของเค้ก ส่งผลให้การตัดมีความแม่นยำและคุณภาพมากขึ้น ช่วงความถี่ทั่วไปที่ใช้คือ เครื่องตัดเค้กอัลตราโซนิก 20 kHz ถึง 40 kHz ซึ่งถูกปรับแต่งอย่างละเอียดเพื่อให้ได้ผลลัพธ์การตัดที่ดีที่สุดโดยไม่ทำลายเนื้อสัมผัสของเค้ก เทคโนโลยีนี้กำลังปฏิวัติวิธีการตัดเค้ก ทำให้กระบวนการนี้เร็วและมีประสิทธิภาพมากขึ้นสำหรับคนอบขนมที่ต้องการความสมบูรณ์แบบ

ส่วนประกอบสำคัญของเครื่องตัดอัลตราโซนิก

เครื่องตัดด้วยคลื่นอัลตราโซนิกประกอบด้วยส่วนประกอบหลักหลายอย่างที่เป็นรากฐานของเทคนิคการตัดขั้นสูงนี้ โดยเฉพาะอย่างยิ่ง เครื่องมีจีเนเรเตอร์ ทรานสดิวเซอร์ และใบมีดตัด ซึ่งแต่ละชิ้นมีบทบาทสำคัญในการสนับสนุนกระบวนการตัด ทรานสดิวเซอร์มีความสำคัญเพราะมันแปลงพลังงานไฟฟ้าเป็นพลังงานกล สร้างการสั่นสะเทือนแบบอัลตราโซนิกที่ถูกถ่ายโอนไปยังใบมีด การสั่นสะเทือนเหล่านี้ทำให้ใบมีดสามารถเลื่อนผ่านเค้กได้อย่างลื่นไหล ผลิตชิ้นส่วนที่สะอาดและแม่นยำ เครื่องขั้นสูงยิ่งเพิ่มความยืดหยุ่นโดยการรวมตัวเลือกปรับความถี่ มอบความยืดหยุ่นในการรองรับประเภทและเนื้อสัมผัสของเค้กที่แตกต่างกัน เพื่อให้แน่ใจว่าแต่ละชิ้นตรงตามมาตรฐานที่ผู้อบขนมต้องการ

เพื่อศึกษาลึกซึ้งเกี่ยวกับวิธีการตัดเค้กด้วยคลื่นอัลตราโซนิก ลองสำรวจตัวเลือก เช่น Cheersonic's Inline-UFM8000 Ultrasonic Cutter ซึ่งสนับสนุนการผลิตความเร็วสูงสำหรับสถานที่เชิงพาณิชย์

ประโยชน์ของการใช้เครื่องตัดเค้กด้วยคลื่นอัลตราโซนิก

การตัดที่แม่นยำสำหรับการนำเสนอที่สมบูรณ์แบบ

เครื่องตัดเค้กด้วยคลื่นอัลตราโซนิกมอบความแม่นยำที่ไม่มีใครเทียบได้ ช่วยให้ขอบเค้กเรียบเนียนและสะอาด ทำให้การนำเสนอเค้กสมบูรณ์แบบ เทคโนโลยีนี้มีความสำคัญอย่างยิ่งสำหรับงานระดับสูงและร้านเบเกอรี่โกศมเมอร์ที่ความสวยงามมีความสำคัญเป็นพิเศษ การศึกษาแสดงให้เห็นว่าการตัดด้วยคลื่นอัลตราโซนิกลดความจำเป็นในการแก้ไขของผู้ตกแต่งลงอย่างมากเนื่องจากคุณภาพของการตัดที่ยอดเยี่ยม นอกจากนี้ยังช่วยเพิ่มความสวยงามของเค้กและเพิ่มประสิทธิภาพในการดำเนินงานของร้านเบเกอรี่ ทำให้กระบวนการทำงานลื่นไหลขึ้น

ลดของเสียและเพิ่มความสะอาด

หนึ่งในข้อดีเด่นของการใช้เทคโนโลยีอัลตราโซนิกในการตัดเค้กคือความสามารถในการลดของเสีย โดยการให้ชิ้นที่สม่ำเสมอและแม่นยำ เครื่องจักรเหล่านี้ช่วยให้ควบคุมสัดส่วนได้อย่างเหมาะสม ซึ่งเป็นสิ่งสำคัญสำหรับการบริหารงบประมาณและการจัดการทรัพยากร นอกจากนี้ การตัดด้วยอัลตราโซนิกที่ละเอียดช่วยลดการเกิด vụนและเศษขยะ ทำให้สภาพแวดล้อมการทำงานสะอาดขึ้นและปฏิบัติตามมาตรฐานด้านอนามัยได้ดียิ่งขึ้น ด้านนี้มีความสำคัญมากขึ้นเรื่อย ๆ ในการรักษา มาตรฐานสุขภาพที่คาดหวังในโรงงานผลิตอาหาร

ความหลากหลายในการจัดการกับเนื้อสัมผัสของเค้กที่แตกต่างกัน

เครื่องอัลตราโซนิกมีความสามารถในการจัดการกับเนื้อสัมผัสของเค้กที่หลากหลาย ตั้งแต่เค้กฟองนุ่มเบาจนถึงชีสเค้กที่หนักและแน่น เซียนี้ทำให้คนอบขนมสามารถทำงานกับสไตล์การทำขนมปังหลายแบบโดยไม่เสียคุณภาพหรือความแม่นยำ ความหลากหลายเช่นนี้เป็นประโยชน์ในครัวขนาดเล็กที่เน้นความสร้างสรรค์ และสภาพแวดล้อมเชิงพาณิชย์ที่เน้นการผลิตอย่างต่อเนื่อง โดยการรองรับการออกแบบของหวานที่ซับซ้อนและเนื้อสัมผัสที่ละเอียดอ่อน เครื่องอัลตราโซนิกช่วยให้คนอบขนมขยายตัวเลือกของพวกเขาโดยไม่ลดคุณภาพลง

การปรับแต่งความถี่อัลตราโซนิกสำหรับประเภทเค้กต่างๆ

การปรับตั้งค่าสำหรับเค้กนุ่มและเค้กหนาแน่น

การปรับความถี่อัลตราโซนิกให้เหมาะสมสำหรับความหนาแน่นที่แตกต่างกันของเค้กเป็นสิ่งสำคัญในการได้มาซึ่งชิ้นเค้กที่เนียนเรียบ เค้กที่นุ่ม เช่น เค้กฟองน้ำ ต้องการพลังงานน้อยกว่าสำหรับการตัดที่ดีที่สุด ในขณะที่เค้กที่หนาแน่น เช่น เค้กชีส จะได้รับประโยชน์จากความถี่และแอมปลิจูดที่เพิ่มขึ้น การปรับแต่งนี้จะช่วยเพิ่มความแม่นยำของการตัดและรักษาความสมบูรณ์ของเค้ก ป้องกันไม่ให้เกิดการพังทลายหรือผิดรูประหว่างการตัด ความคิดเห็นจากเชฟและผู้ปฏิบัติงานแสดงให้เห็นอย่างต่อเนื่องว่า เมื่อตั้งค่าอัลตราโซนิกอย่างละเอียด คุณภาพของชิ้นเค้กจะดีขึ้นอย่างชัดเจน ส่งผลให้ลูกค้าพอใจมากขึ้นเนื่องจากการนำเสนอชิ้นเค้กที่สม่ำเสมอ

การเลือกใบมีดสำหรับขนมหวานเฉพาะทาง

การเลือกออกแบบใบมีดที่เหมาะสมเป็นสิ่งสำคัญเมื่อทำงานกับขนมหวานเฉพาะทาง เช่น เค้กชั้นหรือมูส เค้กประเภทนี้มีโครงสร้างที่บอบบางซึ่งสามารถถูกทำลายได้ง่ายหากใช้ใบมีดผิดประเภท วัสดุของใบมีดต่าง ๆ เช่น ไทเทเนียมหรือสเตนเลส ส่งผลต่อความทนทานและการทำงาน โดยให้ข้อดีที่แตกต่างกันขึ้นอยู่กับเนื้อสัมผัสและระดับความซับซ้อนของเค้ก การเลือกใบมีดที่เหมาะสมสำหรับขนมหวานที่ละเอียดอ่อนเหล่านี้ จะช่วยให้ชั้นของเค้กยังคงสมบูรณ์ ทำให้ผลิตภัณฑ์สุดท้ายมีลักษณะสวยงามและประณีต การเลือกเครื่องมือที่เหมาะสมสำหรับขนมหวานแต่ละประเภทจึงเป็นสิ่งสำคัญเพื่อรักษาความสวยงามและความแข็งแรงของแต่ละชิ้น

ค้นพบประโยชน์ของการใช้เครื่องตัดอัลตราโซนิกความเร็วสูงออนไลน์จาก Cheersonic

เพื่อเพิ่มประสิทธิภาพในการดำเนินงานของร้านเบเกอรี่ของคุณ ควรพิจารณาใช้เครื่องตัดด้วยคลื่นเสียงความถี่สูงรุ่นล่าสุดจาก Cheersonic เช่น รุ่น "UFM8000" ซึ่งสามารถปรับปรุงประสิทธิภาพและความแม่นยำของการตัดได้อย่างมาก เครื่องเหล่านี้ทำงานโดยใช้การสั่นสะเทือนความถี่สูง ช่วยให้ตัดได้อย่างแม่นยำและรักษาความสมบูรณ์ของขนมและรสชาติไว้ได้ เหมาะสำหรับผู้เชี่ยวชาญที่ต้องการความเร็วและความแม่นยำในกระบวนการผลิต!

เคล็ดลับการบำรุงรักษาเพื่อสมรรถนะที่คงที่

แนวทางการขัดและเปลี่ยนใบมีด

การบำรุงรักษาเป็นประจำของใบมีดตัดแบบอัลตราโซนิกเป็นสิ่งสำคัญเพื่อรักษาประสิทธิภาพและความแม่นยำในการตัด ใบมีดที่ขุนไม่เพียงแต่จะทำให้ชิ้นงานตัดไม่สม่ำเสมอเท่านั้น แต่ยังเพิ่มเศษวัสดุทิ้ง ซึ่งอาจกระทบต่อคุณภาพของผลิตภัณฑ์สำเร็จรูป การเจียรใบมีดอย่างสม่ำเสมอมีส่วนช่วยในการรักษาประสิทธิภาพในการตัด ทำให้ทุกครั้งที่ตัดสมบูรณ์แบบ นอกจากนี้ การสร้างตารางตรวจสอบใบมีดสามารถยืดอายุการใช้งานของเครื่องตัดได้อย่างมาก โดยการตรวจสอบความเสียหายเป็นระยะๆ ผู้ปฏิบัติงานสามารถเปลี่ยนใบมีดได้ทันเวลา ทำให้การผลิตมีประสิทธิภาพและน่าเชื่อถืออย่างต่อเนื่อง

การใช้น้ำมันหล่อลื่นที่ปลอดภัยสำหรับอาหารเพื่อความคงทน

เพื่อเพิ่มอายุการใช้งานของเครื่องตัดด้วยคลื่นเสียงความถี่สูง การใช้น้ำมันหล่อลื่นที่ปลอดภัยสำหรับอาหารกับชิ้นส่วนที่เคลื่อนที่เป็นสิ่งสำคัญ น้ำมันหล่อลื่นเหล่านี้ช่วยลดแรงเสียดทานและป้องกันการสึกหรอ ซึ่งช่วยให้เครื่องทำงานอย่างต่อเนื่องในระยะยาว นอกจากนี้ การปฏิบัติเช่นนี้ยังช่วยเพิ่มอายุการใช้งานของเครื่องจักร และสนับสนุนให้ปฏิบัติตามมาตรฐานความปลอดภัย รับรองว่าผลิตภัณฑ์จะไม่ปนเปื้อน การตรวจสอบบำรุงรักษาควรทำเป็นประจำ และควรมีกำหนดการหล่อลื่นที่บันทึกไว้เพื่อให้เป็นไปตามข้อกำหนด มาตรการเชิงรุกเหล่านี้สามารถป้องกันการเสียหายที่อาจเกิดขึ้น และขยายอายุการใช้งานของเครื่อง เพื่อรักษาสายการผลิตให้ไม่มีข้อขัดข้อง

แนวทางปฏิบัติที่ดีที่สุดสำหรับผู้ปฏิบัติงานในการตัดอย่างมีประสิทธิภาพ

การเรียนรู้เทคนิคการกดด้วยแรงคงที่

เพื่อให้ได้มาซึ่งการตัดที่สม่ำเสมอโดยใช้เครื่องตัดเค้กแบบอัลตราโซนิก ผู้ปฏิบัติงานจำเป็นต้องเชี่ยวชาญในศิลปะของการใช้แรงกดอย่างคงที่ การฝึกอบรมผู้ปฏิบัติงานให้สามารถใช้แรงกดที่เท่ากันระหว่างการตัดเป็นสิ่งสำคัญ เนื่องจากความแปรปรวนอาจทำให้ผลลัพธ์ไม่สม่ำเสมอและคุณภาพของผลิตภัณฑ์ลดลง โดยการจัดการฝึกฝนเป็นประจำ ผู้ปฏิบัติงานสามารถพัฒนาทักษะและความสามารถในการค้นหาแรงกดที่เหมาะสมสำหรับประเภทเค้กต่างๆ เพื่อให้แน่ใจว่าจะได้ชิ้นเค้กที่สมบูรณ์แบบทุกครั้ง การฝึกอบรมอย่างต่อเนื่องเป็นสิ่งสำคัญเพื่อรักษาเทคนิคการกดอย่างคงที่ และทำให้แต่ละชิ้นเค้กดูมืออาชีพที่สุด

โปรแกรมฝึกอบรมเพื่อควบคุมคุณภาพ

การนำโปรแกรมฝึกอบรมที่มีโครงสร้างมาใช้เป็นสิ่งสำคัญในการเสริมสร้างความสามารถให้ผู้ปฏิบัติงานสามารถใช้งานเครื่องตัดด้วยคลื่นอัลตราโซนิกได้อย่างมีประสิทธิภาพ ซึ่งช่วยลดข้อผิดพลาดและเพิ่มคุณภาพของผลผลิต การฝึกอบรมเหล่านี้ควรเน้นไปที่การศึกษาผู้ปฏิบัติงานเกี่ยวกับเทคโนโลยีอัลตราโซนิกอย่างครอบคลุม และติดตามความก้าวหน้าใหม่ ๆ เพื่อรักษามาตรฐานที่สูงในสภาพแวดล้อมการแปรรูปอาหาร โดยการให้ความรู้แก่พนักงานอย่างต่อเนื่องเกี่ยวกับแนวทางปฏิบัติที่ดีที่สุดและความก้าวหน้าทางเทคโนโลยีล่าสุด ธุรกิจสามารถรับรองการควบคุมคุณภาพอย่างสม่ำเสมอและการผลิตที่มีประสิทธิภาพ ซึ่งจะช่วยเพิ่มความพึงพอใจของลูกค้าและเพิ่มประสิทธิภาพในการดำเนินงาน

คำถามที่พบบ่อย

เทคโนโลยีการตัดแบบอัลตราโซนิกคืออะไร?

เทคโนโลยีการตัดด้วยคลื่นอัลตราโซนิกใช้คลื่นเสียงความถี่สูงเพื่อทำการตัดเค้กอย่างแม่นยำ ลดการเกาะติดระหว่างชั้นเพื่อให้ได้แผ่นตัดที่สมบูรณ์แบบ

คลื่นอัลตราโซนิกช่วยเพิ่มประสิทธิภาพในการตัดเค้กอย่างไร?

การสั่นสะเทือนด้วยคลื่นอัลตราโซนิกใช้การสั่นสะเทือนอย่างรวดเร็วซึ่งช่วยให้ตัดได้อย่างสะอาดโดยไม่มีการบดหรือแตกหัก ทำให้คุณภาพและความสม่ำเสมอของการตัดดีขึ้น

องค์ประกอบสำคัญของเครื่องตัดแบบอัลตราโซนิกมีอะไรบ้าง?

องค์ประกอบหลักของเครื่องตัดแบบอัลตราโซนิกประกอบด้วย เครื่องกำเนิดสัญญาณ เซนเซอร์แปลงสัญญาณ และใบมีดตัด ทำงานร่วมกันเพื่อสร้างชิ้นเค้กที่แม่นยำ

การตัดแบบอัลตราโซนิกช่วยอะไรให้กับร้านเบเกอรี่?

การตัดแบบอัลตราโซนิกช่วยร้านเบเกอรี่โดยการให้การตัดที่แม่นยำ ลดขยะ เพิ่มความสะอาด และจัดการกับเนื้อสัมผัสของเค้กที่หลากหลายได้อย่างมีประสิทธิภาพ

ทำไมการเลือกใบมีดถึงสำคัญในกระบวนการตัดเค้กด้วยระบบอัลตราโซนิก?

การเลือกใบมีดมีความสำคัญเพราะการออกแบบและวัสดุของใบมีดเฉพาะจะเหมาะกับเนื้อสัมผัสของเค้กแต่ละประเภท ช่วยรักษาโครงสร้างและความสวยงามของชิ้นเค้ก

Table of Contents

- การทำงานของเทคโนโลยีการตัดด้วยคลื่นเสียงความถี่สูงสำหรับชิ้นเค้กที่สมบูรณ์แบบ

- วิทยาศาสตร์เบื้องหลังการสั่นสะเทือนแบบอัลตราโซนิก

- ส่วนประกอบสำคัญของเครื่องตัดอัลตราโซนิก

- ประโยชน์ของการใช้เครื่องตัดเค้กด้วยคลื่นอัลตราโซนิก

- การปรับแต่งความถี่อัลตราโซนิกสำหรับประเภทเค้กต่างๆ

- เคล็ดลับการบำรุงรักษาเพื่อสมรรถนะที่คงที่

- แนวทางปฏิบัติที่ดีที่สุดสำหรับผู้ปฏิบัติงานในการตัดอย่างมีประสิทธิภาพ

- คำถามที่พบบ่อย