Ultrasonic Cake Cutting Machine: Tips for Flawless and Efficient Slicing

Achieving perfect slices of cakes and pastries can be challenging with traditional cutting methods. Wanlisonic, with over 20 years of experience in the bakery industry, offers advanced Ultrasonic Cake Cutting Machines that enable flawless, precise, and efficient slicing for bakeries and food production facilities worldwide. Committed to innovation, Wanlisonic focuses on enhancing ultrasonic technology to provide high-end, reliable cutting solutions that improve productivity and maintain product quality.

Using an Ultrasonic Cake Cutting Machine allows bakeries to maintain consistent slice thickness, reduce waste, and enhance the visual appeal of their products. With precision control, ease of operation, and hygienic design, these machines have become essential tools in modern bakeries.

Understanding Ultrasonic Cake Cutting Machines

What an Ultrasonic Cake Cutting Machine Does

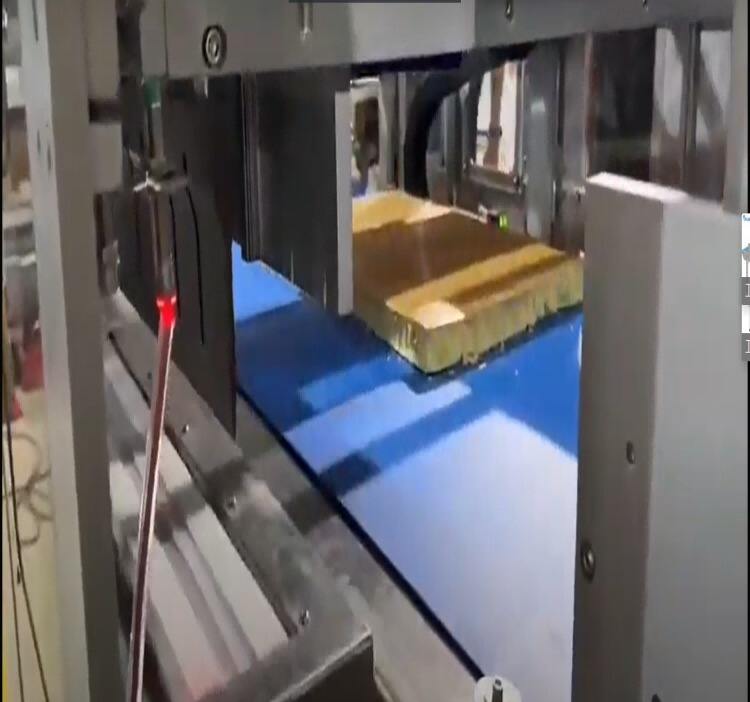

Ultrasonic Cake Cutting Machines utilize high-frequency vibrations to cut through cakes, pastries, and other baked goods cleanly and efficiently. The ultrasonic blade minimizes sticking, ensures smooth edges, and allows faster slicing compared to conventional knives.

How It Differs from Traditional Cutting Methods

Unlike manual cutting or standard electric slicers, ultrasonic machines provide precise, uniform cuts without compressing or deforming the product. Wanlisonic machines also reduce the need for frequent blade cleaning and maintenance, increasing productivity.

Advantages of Ultrasonic Cake Cutting Machines

These machines improve efficiency, maintain product quality, minimize waste, and enhance safety for bakery staff. Consistent, attractive slices improve customer satisfaction and support premium branding.

Key Features to Consider

Precision and Slice Consistency

High-quality Ultrasonic Cake Cutting Machines allow adjustable slice thickness and ensure uniform cuts for all products. Wanlisonic machines offer precision control for diverse bakery items, from soft sponge cakes to dense cheesecakes.

Hygiene and Food Safety

Ultrasonic blades prevent sticking and cross-contamination. Machines are made of stainless steel and other food-grade materials, complying with hygiene standards and making cleaning straightforward.

Speed and Efficiency

Ultrasonic technology allows rapid slicing, reducing manual labor and improving workflow in busy bakery environments. Wanlisonic machines combine speed with precision for optimal operational efficiency.

Durability and Reliability

Robust construction, high-quality components, and long-lasting ultrasonic blades ensure machines operate consistently under high-volume production conditions. Wanlisonic emphasizes quality-first manufacturing for extended service life.

Tips for Flawless Slicing with Ultrasonic Cake Cutting Machines

Proper Machine Setup

Ensure the Ultrasonic Cake Cutting Machine is properly calibrated for the type and size of the cake. Adjust blade vibration frequency and slicing speed for best results.

Choosing the Right Blade

Select ultrasonic blades suitable for specific cake textures. Wanlisonic provides blades designed for soft, medium, or dense baked goods to maintain smooth and clean cuts.

Regular Cleaning and Maintenance

Routine cleaning prevents buildup on the blade and maintains hygiene. Wanlisonic machines are designed for easy disassembly and cleaning to minimize downtime.

Operator Training

Proper training ensures safe operation and optimal performance. Skilled operators can adjust settings, handle different cake types, and maintain machines efficiently.

Consistent Product Preparation

Evenly baked and properly cooled cakes slice better with ultrasonic machines. Preparing products consistently ensures precise cuts and minimizes waste.

Benefits of Using Ultrasonic Cake Cutting Machines in Bakeries

Increased Productivity

Machines can slice more cakes in less time, reducing labor costs and improving bakery output.

Improved Product Quality

Consistent, smooth slices enhance presentation and maintain structural integrity, improving customer satisfaction.

Reduced Waste

Minimizing tearing, crumbling, and deformation results in less product waste and better profit margins.

Enhanced Safety

Ultrasonic cutting reduces manual handling of knives, lowering the risk of workplace injuries.

Versatility Across Products

From sponge cakes and layer cakes to cheesecakes and pastries, ultrasonic machines handle diverse bakery items with ease.

Best Practices for Maintaining Ultrasonic Cake Cutting Machines

Scheduled Maintenance

Follow manufacturer guidelines for routine inspections, blade replacement, and ultrasonic system checks.

Proper Storage

Store machines in dry, clean environments to prevent corrosion and maintain longevity.

Monitor Performance

Track slicing efficiency, blade wear, and vibration consistency to ensure optimal operation.

Upgrading Technology

Consider enhancements such as automated feeding systems or adjustable cutting tables to improve workflow. Wanlisonic continues to innovate to meet modern bakery demands.

FAQ

What is an Ultrasonic Cake Cutting Machine

An Ultrasonic Cake Cutting Machine uses high-frequency vibrations to slice cakes and pastries cleanly and efficiently, reducing waste and improving consistency.

How does Wanlisonic support bakery operations

Wanlisonic provides machines with precise control, hygienic design, robust construction, and operator training to maximize efficiency and product quality.

Can ultrasonic machines improve productivity in bakeries

Yes, they allow faster slicing, consistent cuts, and reduce manual labor, significantly enhancing overall bakery productivity.

What maintenance is required for ultrasonic cake cutting machines

Regular cleaning, blade inspection, vibration system checks, and proper storage ensure consistent performance and long service life.

Table of Contents

- Ultrasonic Cake Cutting Machine: Tips for Flawless and Efficient Slicing

- Understanding Ultrasonic Cake Cutting Machines

- Key Features to Consider

- Tips for Flawless Slicing with Ultrasonic Cake Cutting Machines

- Benefits of Using Ultrasonic Cake Cutting Machines in Bakeries

- Best Practices for Maintaining Ultrasonic Cake Cutting Machines

- FAQ

-

What is an Ultrasonic Cake Cutting Machine

- An Ultrasonic Cake Cutting Machine uses high-frequency vibrations to slice cakes and pastries cleanly and efficiently, reducing waste and improving consistency.

- How does Wanlisonic support bakery operations

- Can ultrasonic machines improve productivity in bakeries

- What maintenance is required for ultrasonic cake cutting machines