What Is the Function of a Bread and Cake Depanner Machine

In the modern baking industry, efficiency, precision, and consistency are the keys to success. Commercial bakeries produce thousands of loaves of bread and cakes every day, and each product must not only taste good but also look visually appealing. One of the critical stages in the production line is the removal of baked goods from their pans or trays. This process might sound simple, but when scaled to industrial production, it becomes a complex challenge. This is where the Cake Depanner Machine plays an essential role.

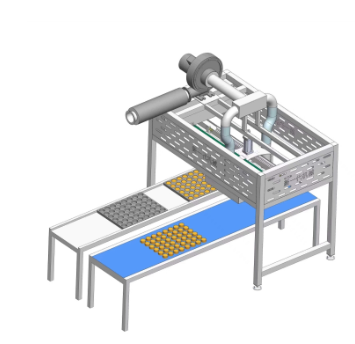

A Cake Depanner Machine is a specialized piece of equipment designed to automate the removal of baked goods such as bread, cakes, muffins, and pastries from baking pans or molds. It ensures that delicate products are removed without damage, maintaining both product quality and production speed. For bakeries that handle large volumes, the Cake Depanner Machine is not just a convenience—it is a necessity.

This article explores the function of a Cake Depanner Machine, its importance in modern bakeries, the types of depanners available, and the benefits it provides to manufacturers who want to achieve consistency and efficiency in their production lines.

Why the Cake Depanner Machine Is Essential

In small-scale baking, removing cakes and bread from pans may be as simple as tapping the pan or using a spatula. However, in industrial baking, where thousands of products are produced per hour, manual depanning is not practical. Human labor is not only slow but also inconsistent, leading to issues such as:

Damaged products due to rough handling.

Inconsistent production speeds.

Increased labor costs.

Hygiene concerns from excessive handling.

The Cake Depanner Machine solves these issues by providing a fast, hygienic, and reliable method of removing products from pans. It ensures uniformity, reduces waste, and increases the efficiency of the overall production line.

How a Cake Depanner Machine Works

The Cake Depanner Machine uses suction, vibration, or mechanical lifting to remove products from pans without causing structural damage. Depending on the type of baked goods and the production requirements, different technologies may be used.

Suction Depanners

These machines use vacuum suction cups to grip the surface of the baked product gently and lift it out of the pan. Suction depanners are ideal for delicate products like sponge cakes, muffins, or cupcakes, where structural integrity must be maintained.

Needle or Pin Depanners

Needle depanners use fine pins or needles that gently insert into the product’s surface to lift it out. This type is commonly used for products with firmer textures, such as bread rolls or pound cakes.

Belt and Roller Depanners

In this system, belts or rollers help transfer products out of the pan. They are well-suited for bread loaves or products baked in standardized trays.

Hybrid Systems

Some Cake Depanner Machines combine multiple technologies, such as suction and vibration, to handle a wide range of baked goods in the same production line.

Each method is designed to maximize product quality, reduce damage, and increase speed, making the depanning process seamless.

Functions of a Cake Depanner Machine

The primary function of a Cake Depanner Machine is to automate the depanning process, but this involves several key tasks:

Gentle Product Removal

The machine ensures cakes, bread, or muffins are removed carefully without breaking, crumbling, or sticking to the pan.Maintaining Product Consistency

By applying the same depanning method across thousands of items, the Cake Depanner Machine ensures consistent results in terms of shape, structure, and appearance.Increasing Production Speed

With the ability to depan hundreds or thousands of items per hour, the machine drastically speeds up production compared to manual labor.Improving Hygiene

Automated depanning minimizes human contact, reducing contamination risks and helping bakeries meet food safety standards.Reducing Waste

By preventing damage, fewer products are wasted, which improves overall profitability.Supporting Downstream Processes

Depanned products can be easily transferred to cooling conveyors, packaging lines, or decorating stations. This integration ensures smooth workflow within the bakery.

Benefits of Using a Cake Depanner Machine

Efficiency Gains

Automating depanning allows bakeries to handle larger production volumes without increasing labor costs. This efficiency is particularly vital in large-scale commercial bakeries.

Product Quality Preservation

The machine’s gentle handling ensures that products maintain their intended shape and structure. This is especially critical for cakes and delicate items that are easily damaged.

Labor Cost Reduction

Instead of employing multiple workers to manually remove items, bakeries can rely on a single machine to handle the process continuously.

Enhanced Food Safety

Minimizing human handling reduces the chances of contamination, helping bakeries maintain high hygiene standards required in the food industry.

Versatility

Modern Cake Depanner Machines are adjustable and can handle a variety of products, from bread loaves to delicate sponge cakes.

Consistency and Reliability

Unlike manual methods, machines do not tire or make mistakes. This consistency ensures uniform product presentation for customers.

Applications of a Cake Depanner Machine

Cake Depanner Machines are widely used in commercial and industrial bakeries worldwide. Common applications include:

Bread loaves produced in tins.

Muffins, cupcakes, and sponge cakes baked in molds.

Specialty cakes with delicate textures.

Pastries and desserts requiring precise handling.

Gluten-free or alternative baked goods that are prone to crumbling.

Whether for mass-production factories or medium-sized bakeries, these machines are critical to ensuring that baked goods move efficiently from baking to packaging.

Factors to Consider When Choosing a Cake Depanner Machine

Product Type

Different baked goods require different depanning methods. Soft cakes need suction depanners, while firmer breads may work better with needle depanners.

Production Volume

High-output bakeries should invest in larger, automated depanners with faster cycle times. Smaller bakeries may opt for compact or semi-automatic models.

Flexibility

If your bakery produces a wide variety of products, a hybrid depanner capable of handling different textures is a smart investment.

Integration with Production Line

Modern depanners can be integrated with conveyor systems, cooling racks, and packaging machinery, ensuring seamless operation.

Maintenance and Cleaning

Machines with easily removable parts and simple cleaning systems save time and reduce downtime.

Cost and ROI

While Cake Depanner Machines require significant upfront investment, the long-term savings from reduced labor and waste quickly justify the cost.

Maintenance of a Cake Depanner Machine

To ensure longevity and consistent performance, regular maintenance is essential.

Clean suction cups, pins, or belts after every shift to prevent buildup.

Lubricate moving parts as recommended by the manufacturer.

Inspect components for wear and replace them promptly.

Conduct regular performance checks to ensure proper functioning.

Train operators on proper usage and basic troubleshooting.

By maintaining the equipment properly, bakeries can maximize the return on investment and minimize downtime.

Future Trends in Cake Depanner Machines

The baking industry continues to innovate, and depanning technology is no exception. Future advancements are likely to include:

Improved automation: Smarter machines that can adjust settings based on product type.

Robotics integration: Robotic arms for precision handling of complex shapes.

Energy efficiency: Machines designed to consume less power while maintaining performance.

Hygiene-focused designs: More parts made from antimicrobial materials and easier-to-clean surfaces.

Data monitoring: Sensors that track performance, efficiency, and maintenance needs.

These advancements will further streamline bakery operations and ensure even higher product quality.

Conclusion

The Cake Depanner Machine is one of the unsung heroes of the baking industry. It performs the essential function of removing baked goods from their pans with speed, precision, and care. By automating what was once a manual, labor-intensive process, it enhances efficiency, preserves product quality, reduces waste, and upholds food safety standards.

From small bakeries to massive industrial operations, the Cake Depanner Machine is indispensable in modern production lines. It allows bakers to focus on creativity and flavor while ensuring that the logistics of high-volume baking run smoothly. As technology evolves, these machines will only become more advanced, offering greater flexibility, efficiency, and reliability.

FAQ

What types of products can a Cake Depanner Machine handle?

It can handle a wide range of baked goods, including bread, cakes, muffins, cupcakes, pastries, and more.

Is a Cake Depanner Machine suitable for small bakeries?

Yes, smaller models are available for bakeries with lower production volumes, though they may not have the speed of large industrial machines.

How does a Cake Depanner Machine improve hygiene?

By reducing direct human contact with baked goods, it minimizes contamination risks and helps meet food safety standards.

What is the difference between suction and needle depanners?

Suction depanners use vacuum cups to lift delicate items, while needle depanners insert fine pins into firmer products to remove them from pans.

Are Cake Depanner Machines difficult to maintain?

No, with proper cleaning and regular inspections, they are relatively easy to maintain and can last for many years.

Table of Contents

- What Is the Function of a Bread and Cake Depanner Machine

- Why the Cake Depanner Machine Is Essential

- How a Cake Depanner Machine Works

- Functions of a Cake Depanner Machine

- Benefits of Using a Cake Depanner Machine

- Applications of a Cake Depanner Machine

- Factors to Consider When Choosing a Cake Depanner Machine

- Maintenance of a Cake Depanner Machine

- Future Trends in Cake Depanner Machines

- Conclusion

- FAQ