Ժամանակակից տորթեղենի արտադրության հետևից գալիս է հեղափոխական տեխնոլոգիան

Հացահատիկի արդյունաբերությունը գրավիչ փոփոխություններ է կրել ուլտրաձայնային տորթեղենի կտրման սարքերի ներդրման շնորհիվ տորթեղենի կտրման սարքեր այս նորարարական սարքերը հեղափոխություն են կատարել փափուկ տորթերի կտրման գործում՝ առևտրային հացահատիկի արտադրության և սննդի արտադրության կենտրոններում ապահովելով աննախադեպ ճշգրտություն և արդյունավետություն: Տեխնոլոգիան օգտագործում է բարձր հաճախականությամբ թրթռոցներ՝ ստեղծելով մաքուր և ճշգրիտ կտրվածքներ՝ առանց վնասելու փափուկ տորթերի նուրբ կառուցվածքը:

Այսօրվա մրցակցային հացաբուլկեղենի շուկայում արտադրանքի որակը պահպանելը՝ միաժամանակ ավելացնելով արտադրողականությունը, կարևոր է: Ուլտրաձայնային տորթեղենի կտրող մեքենաները լուծում են այս խնդիրը՝ ապահովելով համապատասխան և մասնագիտական արդյունքներ, որոնք ավանդական կտրման մեթոդները պարզապես չեն կարող ապահովել: Տարբեր տորթերի տեքստուրների և բաղադրությունների հետ աշխատելու հնարավորությունը դարձրել է այս տեխնոլոգիան անգնահատելի միջոց ժամանակակից հացաբուլկեղենի գործողություններում:

Ուլտրաձայնային տեխնոլոգիայի հիմնական առավելությունները տորթերի մշակման ընթացքում

Առաջին կարգի ստիպման ու ճշգրտության որոշում

Ուլտրաձայնային տորթեղենի կտրման սարքերը աշխատում են՝ առաջացնելով բարձր հաճախականությամբ թրթռումներ, որոնք կտրող սղոցի վրա առաջացնում են միկրոսկոպիկ շարժումներ: Այս եզակի մեխանիզմը թույլ է տալիս սղոցին կտրել փափուկ տորթերը՝ առաջացնելով նվազագույն ճնշում, ինչը կանխում է տորթի սեղմումը և պահպանում է տորթի սկզբնական կառուցվածքը: Արդյունքում ստացվում են արտասովոր մաքուր կտրվածքներ հարթ եզրերով, որոնք երաշխավորում են, որ յուրաքանչյուր կտորը այնքան հարուստ տեսք ունի, որքան համեղ է:

Այս սարքերի ճշգրտությունը չի սահմանափակվում միայն էսթետիկայով: Դրանք կարող են հաստատականորեն առաջադրել համաչափ կտրվածքներ՝ ճշգրիտ չափերով, ինչը կարևոր է այն առևտրային հացահատիկի թխվածքների համար, որոնք պետք է պահպանեն խիստ հատվածների վերահսկողություն: Այս մակարդակի ճշգրտությունը օգնում է ձեռնարկություններին օպտիմալացնել իրենց պաշարների կառավարումը և ապահովել հաճախորդների բավարարվածությունը՝ ստանդարտացված մատուցման չափերի միջոցով:

Արտադրության արդյունավետության բարձրացում

ՈՒլտրաձայնային տորթեղենի կտրման մեքենաների արագությունը և հուսալիությունը զգալիորեն բարձրացնում են արտադրության արդյունավետությունը: Ավանդական՝ ձեռքով կտրելու մեթոդները շատ ժամանակատար են և աշխատատար, իսկ ուլտրաձայնային տեխնոլոգիան հնարավորություն է տալիս միաժամանակ մշակել մի քանի տորթ, նվազագույն օպերատորական միջամտությամբ: Այս աճող արտադրողականությունը թույլ է տալիս հացաբուլկեղենի արտադրողներին բարձրացված պահանջարկը բավարարել՝ առանց որակից հրաժարվելու:

Ավելին, այս մեքենաները նվազեցնում են արտադրանքի կորուստը՝ վերացնելով սովորական կտրման մեթոդներին բնորոշ խնդիրները, ինչպիսիք են փշրումը և անհավասար կտրվածքները: Ճշգրիտ կտրման գործողությունը ապահովում է յուրաքանչյուր տորթից առավելագույն ելք, ինչը նպաստում է ավելի լավ շահույթի ցուցանիշներին և կայուն գործողություններին:

Տեխնիկական առավելություններ փափուկ տորթերի մշակման ընթացքում

Ավանդական հոդվածի տեխնոլոգիա

ՈՒլտրաձայնային կտրում ունեցող տապակի մեքենաներում օգտագործվող հատուկ սղոցները նախագծված են աշխատելու համատեղ, ուլտրաձայնային հաճախադարձությունների հետ: Այս սղոցները սովորաբար պատրաստված են բարձրորակ տիտանից կամ հատուկ համաձուլվածքներից, որոնք կարող են արդյունավետորեն փոխանցել ուլտրաձայնային թրթռոցներ: Սղոցի նախագիծը նվազագույնի է հասցնում շփման ուժը և կանխում է արտադրանքի կպչելը, ապահովելով համապես կատարում՝ նույնիսկ երկարատև արտադրական շարքերի ընթացքում:

Այս առաջադեմ սղոցների կպչունությունը բացառող հատկությունները վերացնում են հաճախադարձ մաքրման կամ սղոցի փոխարինման անհրաժեշտությունը, ինչը կրճատում է սպասարկման դադարը և երկարաձգում սարքավորումների շահագործման կյանքը: Այս տեխնոլոգիական առաջընթացը ներկայացնում է զգալի բարելավում ավանդական կտրող գործիքների նկատմամբ, որոնք հաճախ պահանջում են կանոնավոր սպասարկում և փոխարինում:

Կարգավորվող կտրման պարամետրեր

Ժամանակակից ուլտրաձայնային տորթեղենի կտրող մեքենաները ընդգրկում են հնարավորություններ տարբեր տեսակի տորթերի համար՝ հաշվի առնելով կտրման արագությունը, լայնությունը և դանակի ջերմաստիճանը՝ օպտիմալ արդյունքներ ստանալու համար։ Այս ճկունությունը ապահովում է լավագույն աշխատանք տարբեր տեքստուրների տորթերի համար՝ սկսած խիտ ֆունտային տորթերից մինչև թեթև և օդային սուֆլեներ։

Տարբեր ապրանքների համար կտրման պրոֆիլներ պահպանելու և վերականգնելու հնարավորությունը պարզեցնում է արտադրության փոփոխությունները և ապահովում համա consistency ամբողջ արտադրային շարքում: Այս կառավարման մակարդակը հատկապես կարևոր է հացահատիկի արտադրության համար, որոնք արտադրում են տարբեր տեսակի տորթեր և պետք է պահպանեն բարձր որակի ստանդարտներ ամբողջ արտադրանքի շարքում:

Իրականացման և շահագործման համար համապատասխան դիտարկումներ

Գոյություն ունեցող արտադրական գծերի ինտեգրում

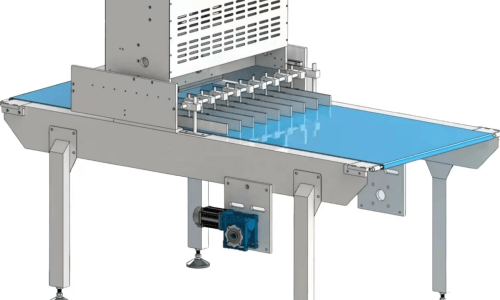

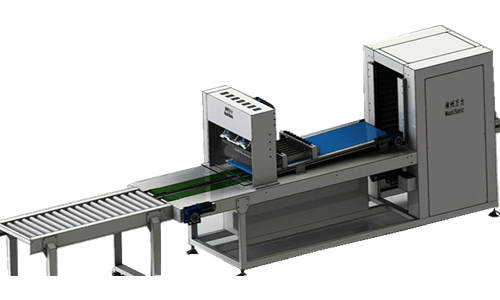

ՈՒլտրաձայնային տորթեղենի կտրող մեքենաների ներդրումը գոյություն ունեցող արտադրական սարքավորումներում հիանալի ձևով պարզ է: Այս մեքենաները նախագծված են մոդուլային կառուցվածքով, որը հեշտությամբ կարող է ինտեգրվել ավտոմատացված արտադրական գծերի մեջ կամ աշխատել որպես առանձին միավորներ: Լճական կառուցվածքը թույլ է տալիս հացահատիկային արտադրություններին աստիճանաբար մասշտաբավորել իրենց գործողությունները՝ պահպանելով արդյունավետությունը:

Ժամանակակից ուլտրաձայնային տորթեղենի կտրող մեքենաների մեծամասնությունն ունի օգտատիրոջ հարմար ինտերֆեյսներ և ինտուիտիվ ղեկավարում, որը նվազագույնի է հասցնում օպերատորների ուսուցման ընթացքը: Օգտագործման հեշտությունը ապահովում է հարթ անցումային շրջաններ և տեխնոլոգիայի արագ ընդունում արտադրական միջավայրում:

Պահպանման և հիգիենայի ստանդարտներ

ՈՒլտրաձայնային տորթեղենի կտրող մեքենաների կառուցվածքը առաջնահերթություն է տալիս հիգիենային և հեշտ պահպանմանը: Հարթ մակերեսները և կնքված մասերը կանխում են սննդամթերքի մասնիկների կուտակումը և հեշտացնում են հիմնական մաքրումը: Կանոնավոր պահպանման պահանջները նվազագույնի են հասցված համեմատած ավանդական կտրող սարքավորումների հետ, ինչը նպաստում է շահագործման ծախսերի կրճատմանը:

Այս մեքենաները հաճախ ներառում են ինքնաշխատ մաքրման ցիկլեր և հանվող մասեր, որոնք պարզեցնում են սանիտարական մաքրման գործընթացը: Այս նախագծման մոտեցումը թույլ է տալիս հացի թխվածքներին պահպանել խիստ սննդի անվտանգության ստանդարտներ՝ նվազագույնի հասցնելով արտադրության ընդհատումները մաքրման և սպասարկման համար:

Ապագայի միտումներ և նորարարություններ

Խելացի տեխնոլոգիաների ինտեգրումը

Ուլտրաձայնային տորթի կտրման մեքենաների ապագան ավելի շատ կենտրոնանում է ինտելեկտուալ տեխնոլոգիաների ինտեգրման վրա: Արտադրողները մշակում են IoT հնարավորություններ ունեցող համակարգեր, որոնք թույլ են տալիս հեռակա հսկողություն, կանխատեսվող սպասարկում և իրական ժամանակում արդյունավետության օպտիմալացում: Այս նվաճումները կբարելավեն տորթի կտրման գործողությունների արդյունավետությունն ու հուսալիությունը:

Ավելի ուշադիր արդյունքներ ստանալու և օպերատորի միջամտությունը կրճատելու համար ավտոմատ կերպով կտրման պարամետրերը օպտիմալացնելու համար ներառվում են առաջադեմ անալիտիկա և մեքենայական ուսուցման ալգորիթմներ՝ հիմնված արտադրանքի բնութագրերի և արտադրության պայմանների վրա:

Կայուն զարգացումներ

Շրջակա միջավայրի նկատմամբ հաշվի առնելը խթանում է ալտրաձայնային տորթեղենի կտրման տեխնոլոգիայում նորարարությունների մշակումը: Նոր մոդելները ստեղծված են էներգախնայող բաղադրիչներով և էկոլորտ նյութերով: Այս մշակումները համապատասխանում են արդյունաբերության աճող կենտրոնացմանը՝ կայուն արտադրական մեթոդների և շրջակա միջավայրի վրա ազդեցության նվազեցման ուղղությամբ:

Արտադրողները նաև աշխատում են լուծումների վրա, որոնք նվազեցնում են ջրի օգտագործումը մաքրման ցիկլերի ընթացքում և ընդհանուր ռեսուրսների սպառումը: Այս բարելավումները օգնում են հացահատիկի թխվածքներին հասնել կայունության նպատակներին՝ պահպանելով բարձր արտադրական ստանդարտներ:

Հաճախ տրվող հարցեր

Ինչպե՞ս են ալտրաձայնային տորթեղենի կտրման մեքենաները վերաբերվում տարբեր տորթերի կոնսիստենցիաներին:

Ալտրաձայնային տորթեղենի կտրման մեքենաները կարող են կարգավորվել՝ հարմարեցնելով տարբեր տորթերի կոնսիստենցիաներին՝ հաճախականության, լայնության և կտրման արագության ընտրելի կարգավորումների միջոցով: Տեխնոլոգիան հատկապես արդյունավետ է փափուկ տորթերի հետ, քանի որ բարձր հաճախականությամբ տատանումները կանխում են սեղմումը և պահպանում են սկզբնական կոնսիստենցիայի ամբողջականությունը:

Ինչ սպասարկում է պահանջվում ալտրաձայնային տորթեղենի կտրման մեքենաների համար:

Այս սարքերը պահանջում են նվազագույն սպասարկում՝ համեմատած ավանդական կտրող սարքավորումների հետ: Սովորաբար բավարար է կանոնավոր մաքրում, պարբեշտաբար կտրիչի ստուգում և երբեմն ուլտրաձայնային գեներատորի ստուգում: Շատ համակարգեր ներառում են ինքնաստուգման հատկություններ, որոնք զգուշացնում են օպերատորներին, երբ անհրաժեշտ է սպասարկում:

Արդյո՞ք ուլտրաձայնային տորթի կտրման սարքերը հարմար են փոքր հացաբուլկեղենի արտադրության համար

Այո, ուլտրաձայնային տորթի կտրման սարքերը հասանելի են տարբեր չափերով և կոնֆիգուրացիաներով՝ հարմարեցված տարբեր արտադրական մասշտաբներին: Փոքր հացաբուլկեղենի արտադրությունները կարող են օգտվել կոմպակտ, առանձին սարքերից, որոնք առաջարկում են նույն ճշգրտությունն ու արդյունավետությունը, ինչ խոշոր արդյունաբերական համակարգերը, սակայն զբաղեցնում են նվազագույն տեղ և պահանջում են նվազագույն ներդրումներ:

Բովանդակության աղյուսակ

- Ժամանակակից տորթեղենի արտադրության հետևից գալիս է հեղափոխական տեխնոլոգիան

- Ուլտրաձայնային տեխնոլոգիայի հիմնական առավելությունները տորթերի մշակման ընթացքում

- Տեխնիկական առավելություններ փափուկ տորթերի մշակման ընթացքում

- Իրականացման և շահագործման համար համապատասխան դիտարկումներ

- Ապագայի միտումներ և նորարարություններ

- Հաճախ տրվող հարցեր